Hollow-fiber membrane module of additional electric field

An additional electric field and fiber membrane technology, applied in the field of devices for removing organic matter or particles in water, can solve the problems that flat membrane devices cannot be applied to water treatment or particle separation processes, and cannot further increase the filtration area for filtration and separation, so as to reduce the concentration difference Effect of Polarization and Membrane Fouling and Efficiency Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

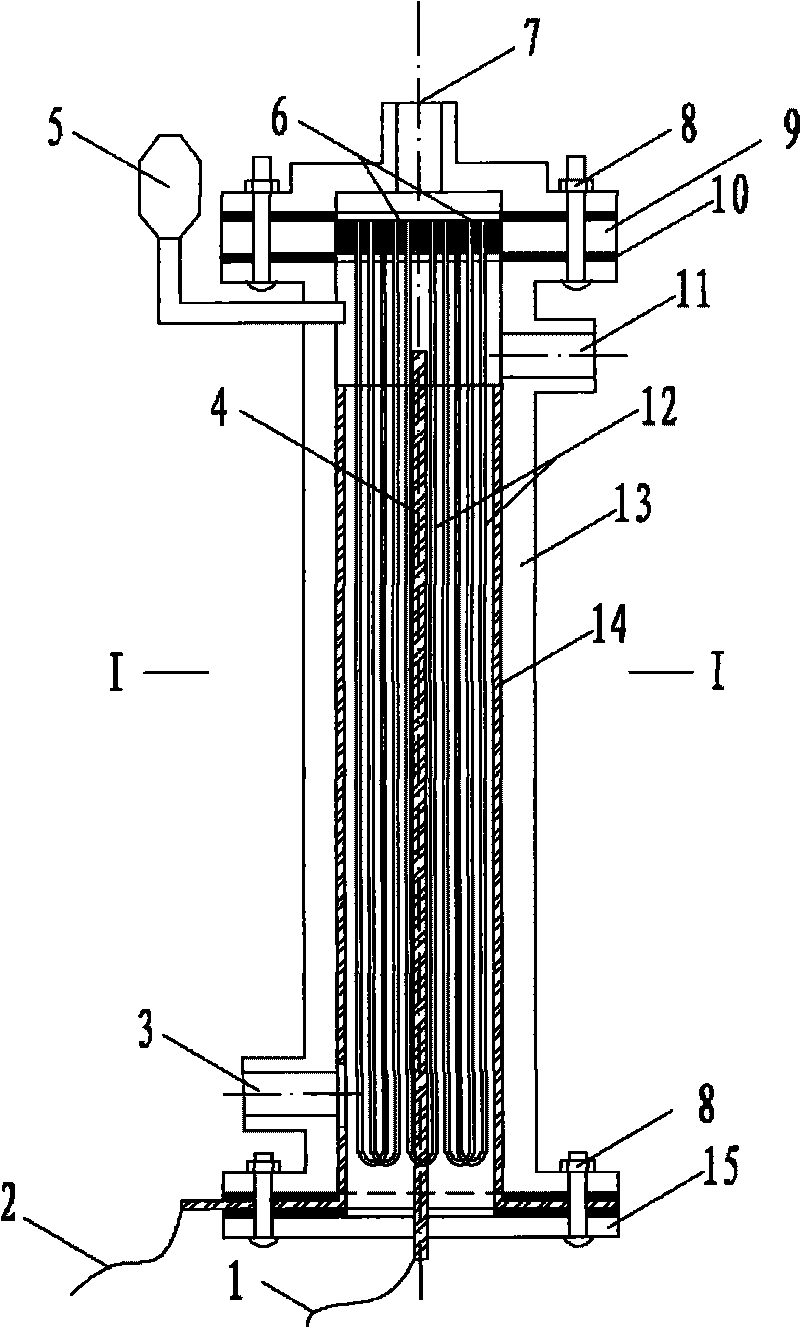

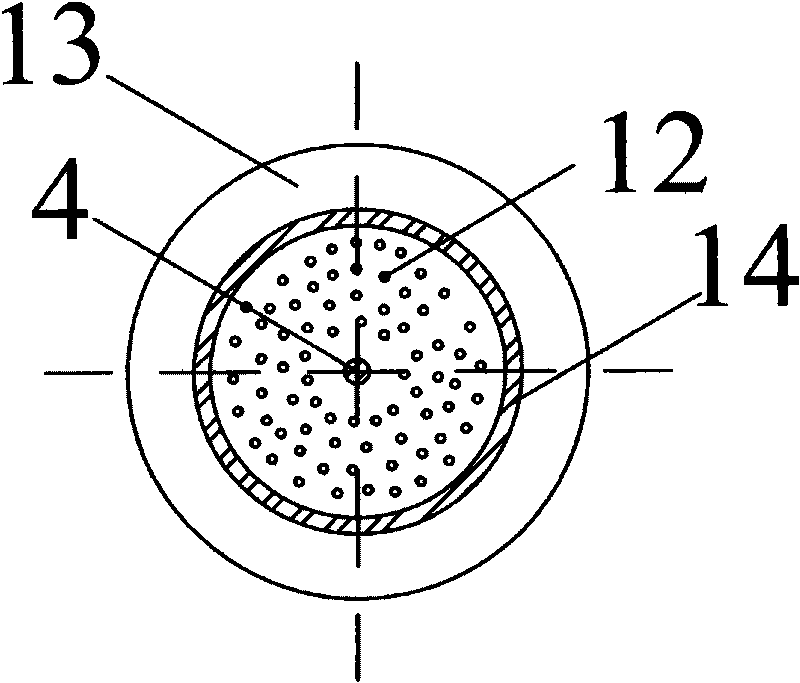

[0015] The present invention will be further described below in conjunction with the drawings and embodiments.

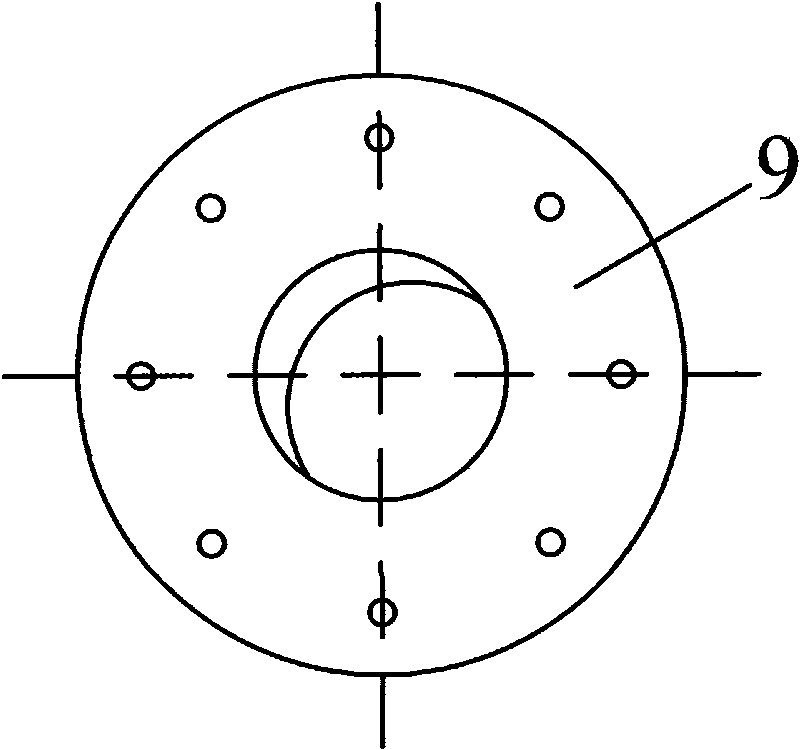

[0016] First, the commercially available hollow fiber membrane filaments 12 are bent into a “U” shape, and the water outlet end of the “U”-shaped hollow fiber membrane filaments 12 and the membrane filament fixing plate 9 are bonded with epoxy resin 6. When the epoxy resin 6 is not hardened, the film filament fixing plate 9 is quickly oscillated on the oscillator, so that the epoxy resin 6 completely penetrates into the gap between the film filaments. After the epoxy resin 6 is hardened, the epoxy resin 6 near the water outlet end of the hollow fiber membrane filament 12 is cut off, so that the water outlet end is exposed outside the epoxy resin glue 6.

[0017] The bottom plate 15 is drilled in the center, and the diameter of the hole is slightly smaller than that of the anode 4. Apply pressure to make anode 4 pass through the bottom

[0018] The small hole in the cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com