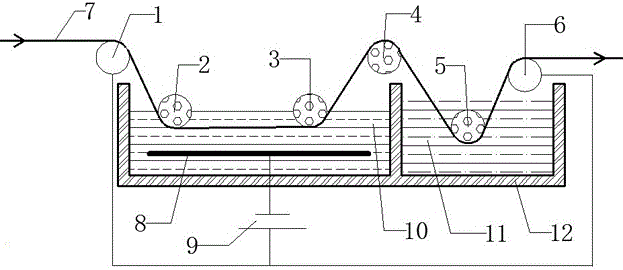

A carbon fiber surface treatment equipment, surface treatment method and application

A technology of surface treatment and carbon fiber, which is applied in the field of carbon fiber surface treatment equipment and surface treatment, can solve the problems of polluted electrolyte, non-conductive anode guide roller, and long time for carbon fiber surface treatment of anode guide roller, so as to improve electrolysis and reduce electrolysis time , Avoid the effect of metal ions contaminating the electrolyte

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Configure the ammonium dihydrogen phosphate electrolyte solution with a mass concentration of 5%, introduce the carbon fiber into the carbon fiber surface treatment equipment for electrochemical treatment, the treatment temperature is 25°C, and the electrolytic current density is controlled at 10mA / cm 2 , treatment time 10s, 100 ℃ direct drying, collect samples; samples are tested for interlayer shear strength according to GB3357-82, performance test data are shown in Table 1.

Embodiment 2

[0028] Configure ammonium dihydrogen phosphate electrolyte solution with a mass concentration of 5%, introduce carbon fiber into carbon fiber surface treatment equipment for electrochemical treatment, the treatment temperature is 25°C, and the electrolytic current density is controlled at 5mA / cm 2 , treatment time 25s, 100 ℃ direct drying, collect samples; samples are tested for interlayer shear strength according to GB3357-82, performance test data are shown in Table 1.

Embodiment 3

[0030] Configure ammonium bicarbonate electrolyte solution with a mass concentration of 2%, introduce carbon fiber into carbon fiber surface treatment equipment for electrochemical treatment, the treatment temperature is 25°C, and the electrolytic current density is controlled at 12mA / cm 2 , treatment time 60s, 100 ℃ direct drying, collected samples; samples according to GB3357-82 test interlayer shear strength, performance test data in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com