Method for preparing gold salt activator

A technology of activator and gold salt, which is applied in the direction of photographic process, instrument, photographic auxiliary process, etc., can solve the problems of terminal electronic product quality improvement, narrow application area, large loss, etc., and achieve the goal of reducing electrolysis time and purification Effect of time and frequency, reduction of mother liquor, and reduction of water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

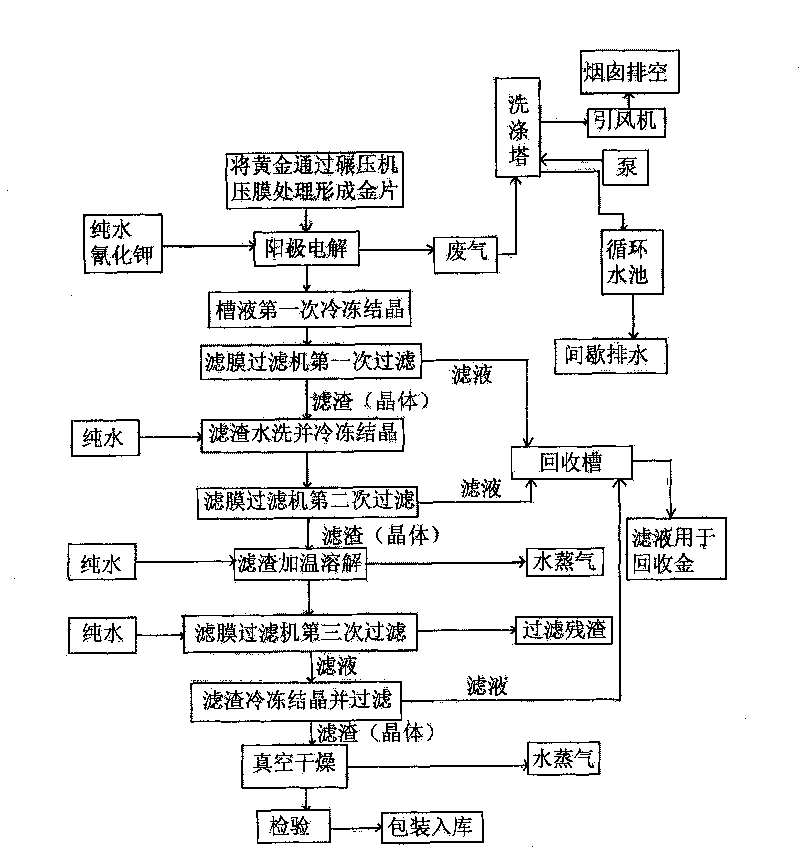

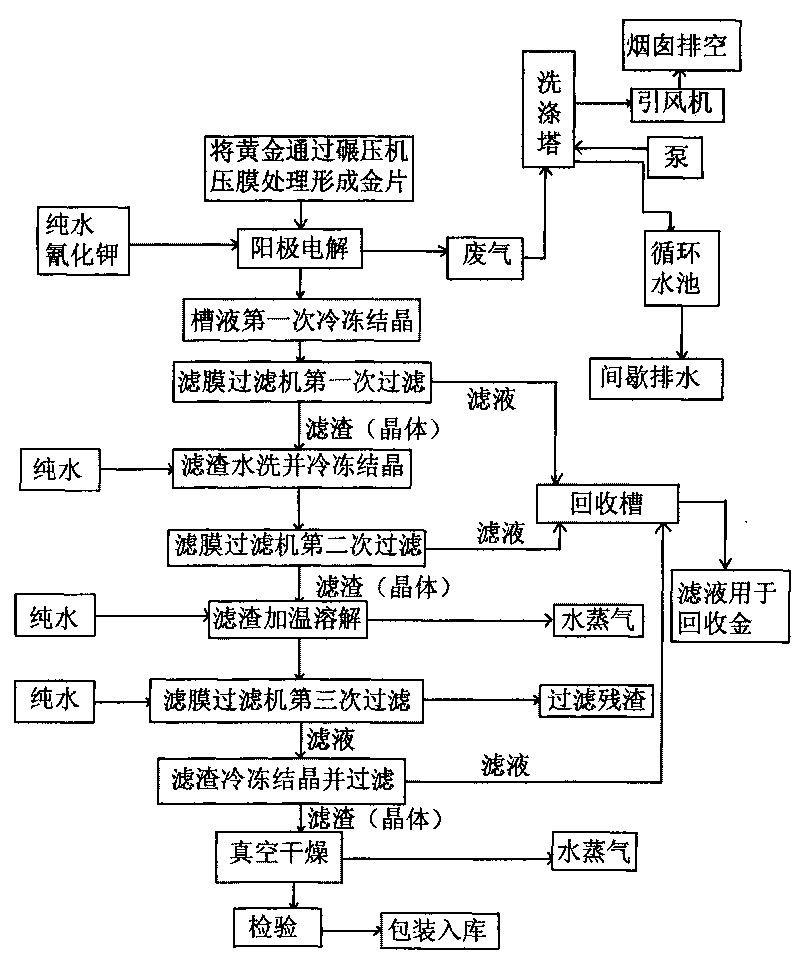

[0008] exist figure 1 Among them, the present invention is a preparation method of a gold salt activator, which includes the following steps: Step 1, first select the raw material, the raw material is gold, and the gold is processed into a gold sheet by a rolling machine; Step 2, Then put the gold sheet into the electrolytic cell with potassium cyanide solution for electrolysis, add electrolyte iron, cobalt, nickel, copper and lead during electrolysis, the amount of iron, cobalt, nickel, copper and lead added is less than or equal to the electrolytic solution 0.0005% of the mass, the initial voltage during electrolysis is 2.8-3.2 volts, the later stage voltage is 6 volts, the electrolysis current is 15-30 milliamperes, and the mass percentage of gold flakes and potassium cyanide in the electrolytic tank is 1: 1.04, gold The sheet is used as the anode, and the gold sheet at the anode is electrolyzed into KAu(CN) 2 , the exhaust gas produced after electrolysis is sent to the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com