A hydrogen reduction tio 2 Combined molten salt electrolysis ti 4 o 7 Method for preparing titanium metal

A technology of molten salt electrolysis and metal titanium, applied in the field of metallurgy, can solve the problems of long electrolysis time, low deoxidation efficiency, long process flow, etc., and achieve the effects of short time, improved current efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

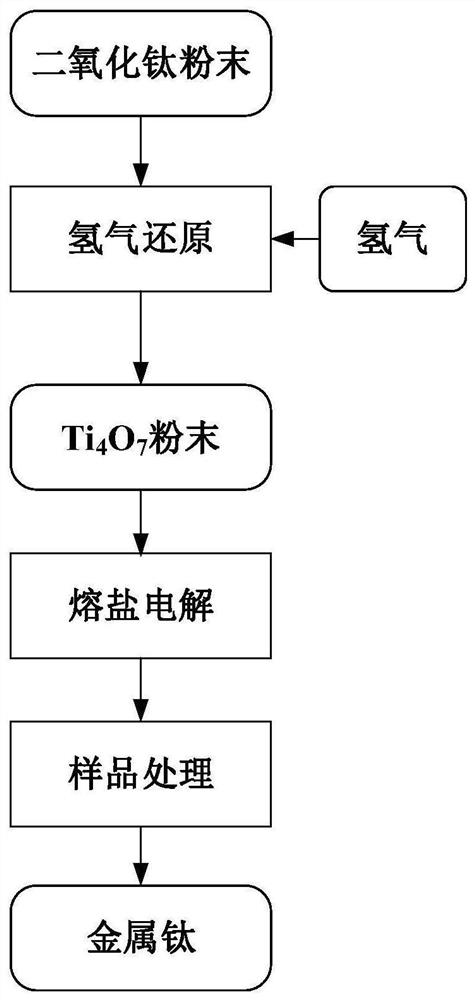

[0032] The technological process of this embodiment is as figure 1 shown. Choose TiO with a purity of ≥99.8% and pass through a 140-mesh sieve 2 powder, adopt the method of the present invention to prepare metal titanium, wherein the time of molten salt electrolysis is 1 hour, and the steps are as follows:

[0033] (1) TiO 2 The powder is spread on the corundum crucible and put into the sealed tubular heating furnace, and the thickness of the laying is controlled below 3mm. After closing the furnace cover, continuously feed argon (the flow rate of argon gas is 250ml / min) to ensure the inert atmosphere in the furnace. After 3 hours, the temperature in the furnace rises from room temperature to 1300°C.

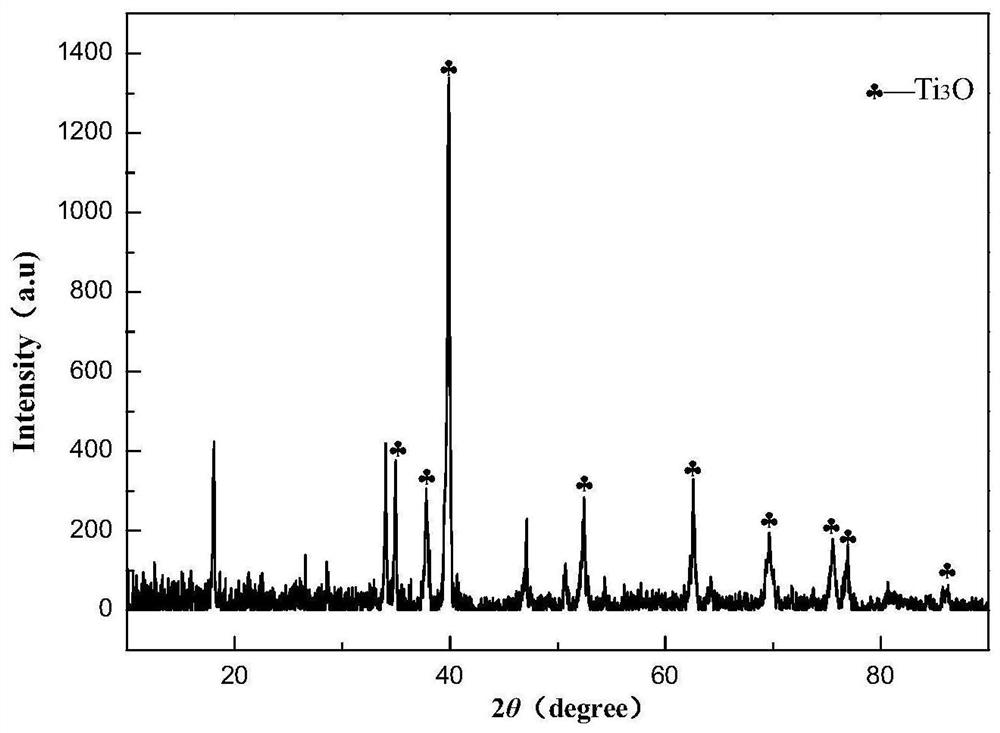

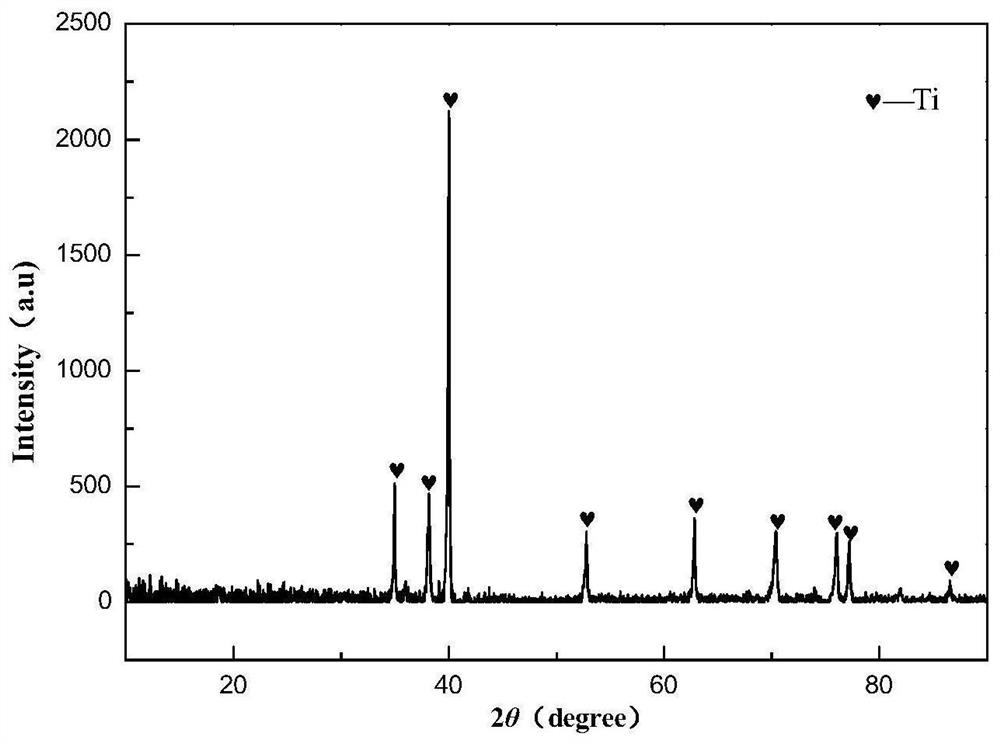

[0034] (2) After the temperature is stabilized, stop feeding argon gas and change it to hydrogen gas (hydrogen gas flow rate is 250ml / min), and keep the temperature at 1300°C for 2 hours, and the obtained Ti 4 o 7 Samples were wrapped with 400-mesh stainless steel gauze as ...

Embodiment 2

[0041] The present embodiment selects the TiO that purity is ≥ 99.8% and crosses 140 mesh sieves for use 2 powder, adopt the method of the present invention to prepare metal titanium, wherein the time of molten salt electrolysis is 6 hours, and the steps are as follows:

[0042] (1) TiO 2 The powder is spread on the corundum crucible and put into the sealed tubular heating furnace, and the thickness of the laying is controlled below 3mm. After the furnace cover is closed, argon gas is continuously introduced (the flow rate of argon gas is 250ml / min) to ensure an inert atmosphere in the furnace. After 3 hours, the temperature in the furnace rises from room temperature to 1300°C.

[0043] (2) After the temperature is stabilized, stop feeding argon gas and change it to hydrogen gas (hydrogen gas flow rate is 250ml / min), and keep the temperature at 1300°C for 2 hours, and the obtained Ti 4 o 7 Samples were wrapped with 400-mesh stainless steel gauze as the cathode raw material ...

Embodiment 3

[0050] The present embodiment selects the TiO that purity is ≥ 99.8% and crosses 140 mesh sieves for use 2 powder, adopt the method of the present invention to prepare metal titanium, wherein the time of molten salt electrolysis is 3 hours, and the steps are as follows:

[0051] (1) TiO 2 The powder is spread on the corundum crucible and put into the sealed tubular heating furnace, and the thickness of the laying is controlled below 3mm. After the furnace cover is closed, argon gas is continuously introduced (the flow rate of argon gas is 250ml / min) to ensure an inert atmosphere in the furnace. After 3 hours, the temperature in the furnace rises from room temperature to 1300°C.

[0052] (2) After the temperature is stabilized, stop feeding argon gas and change it to hydrogen gas (hydrogen gas flow rate is 250ml / min), and keep the temperature at 1300°C for 2 hours, and the obtained Ti 4 o 7 Samples were wrapped with 400-mesh stainless steel gauze as the cathode raw material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com