An electrochemical method for removing heavy metals from excess sludge

An excess sludge, electrochemical technology, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve the secondary pollution of soil, groundwater, animals and plants, acid consumption of chemical treatment methods Large, stabilizing technology solves problems such as symptoms but not the root cause, and achieves the effect of small secondary pollution risk, reliable performance and good removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

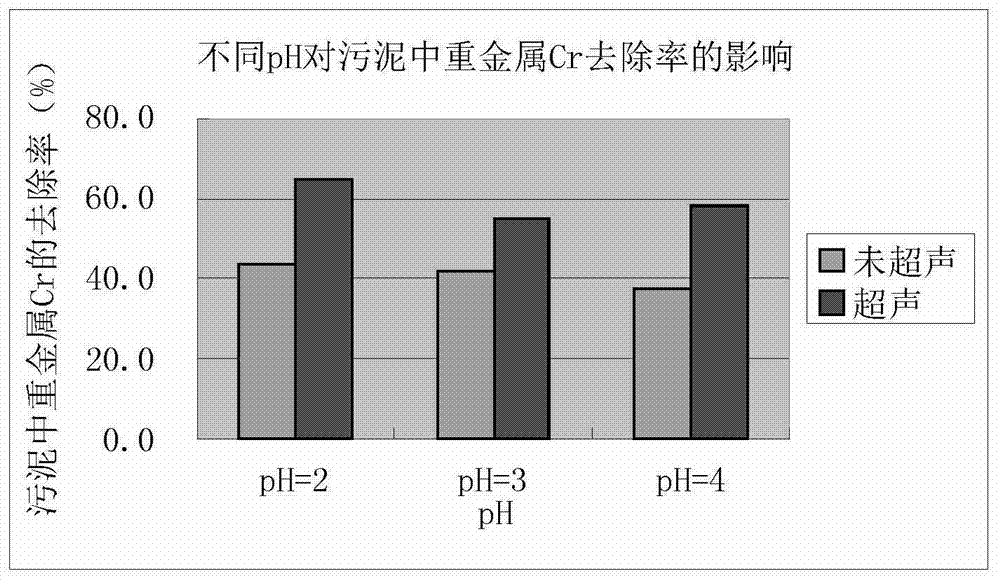

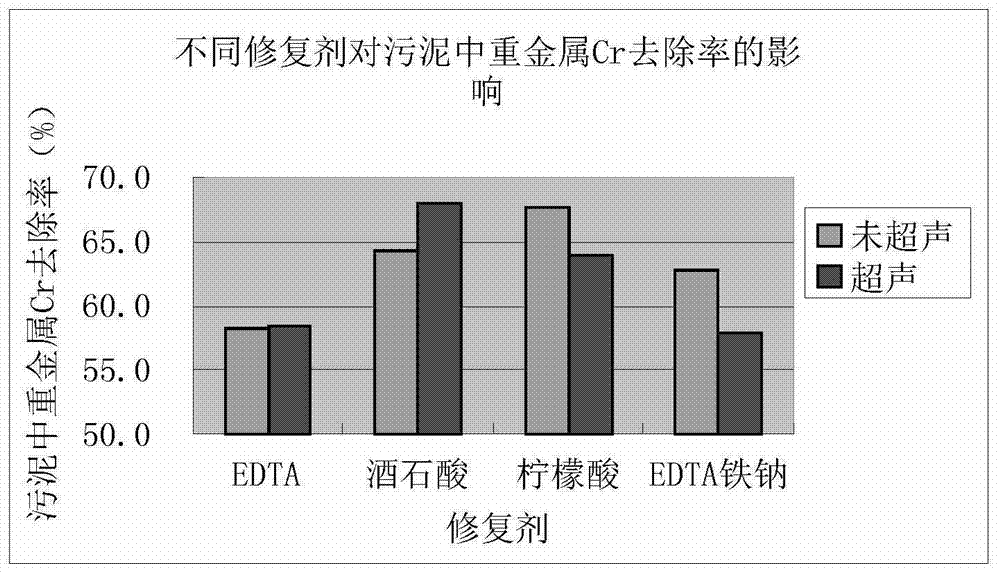

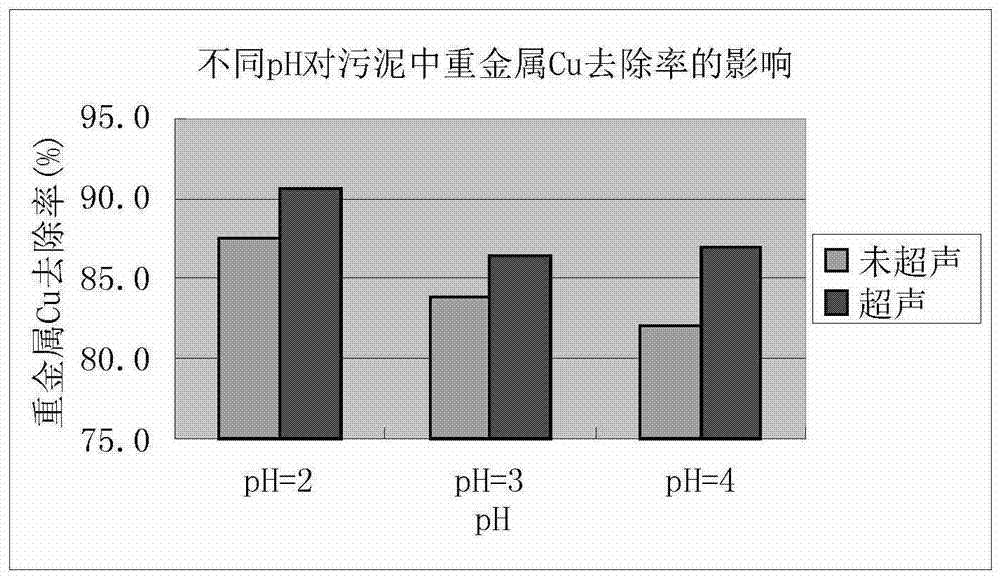

[0035] The contents of heavy metals Cr and Cu in the excess sludge of an urban sewage treatment plant in a certain place were 896 and 10313mg / kg respectively. Weighed 20g of dry sludge and put them into 120ml of 0.1mol / L EDTA, citric acid, tartaric acid and sodium iron EDTA respectively. Ultrasonic oscillation for 7 hours, adjust the pH value to 2-4 with hydrochloric acid, enter the electrochemical device with graphite as the electrode, the voltage is 3.5V, the distance between the plates is 14cm, after 12 hours of electrochemical treatment, the sample is dried and digested, and the detected The remaining heavy metal Cr and Cu contents in the sludge were all within the limit, which met the agricultural standard of sludge. See the specific removal effect Figure 1 ~ Figure 4 .

Embodiment 2

[0037] The contents of heavy metals Ni and Zn in the excess sludge of an urban sewage treatment plant in a certain place were 284 and 1648mg / kg respectively. Weighed 20g of dry sludge and put them into 120ml of 0.1mol / L EDTA, citric acid, tartaric acid and sodium iron EDTA respectively. Ultrasonic oscillation for 7 hours, after adjusting the pH value to 2-4 with hydrochloric acid, enter the electrochemical device with graphite as the electrode, the voltage is 3.5V, the distance between the plates is 14cm, after 12 hours of electrochemical treatment, the sample is dried and digested, and the detection The contents of remaining heavy metals Ni and Zn in the sludge are all within the limit, which meets the agricultural standard of sludge. See the specific removal effect Figure 5 ~ Figure 8 .

Embodiment 3

[0039] The contents of heavy metals Cr, Cu, Ni, and Zn in the excess sludge of an urban sewage treatment plant in a certain place were 896, 1031, 284, and 1648mg / kg respectively. Weighed 20g of dry sludge and put them into 120ml of 0.1mol / L EDTA, lemon Acid, tartaric acid, ultrasonic vibration for 7 hours, after adjusting the pH value to 2 and 3 with hydrochloric acid, enter the electrochemical device with graphite as the electrode, the voltage is 3.5V, the distance between the plates is 14cm, after 12 hours of electrochemical treatment, the sample is dried After digestion, it was detected that the contents of residual heavy metals Cr, Cu, Ni, and Zn in the sludge were all within the limit, which met the agricultural standards for sludge. See the specific removal effect Figure 9 ~ Figure 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com