Electrochemical method for removing heavy metal cadmium in silkworm excrement

An electrochemical and heavy metal technology, applied in the direction of solid waste removal, etc., can solve the problems of different migration speed of heavy metal cations, heavy metals cannot achieve the treatment effect, and different removal rates of heavy metals, etc., to save electrolysis time, improve electrolysis efficiency, and treat fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

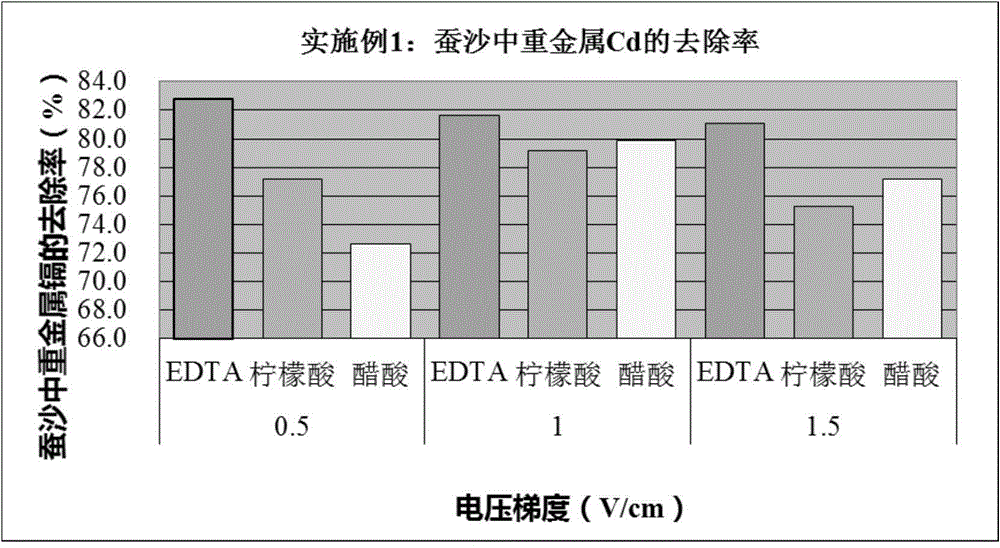

Embodiment 1

[0028] The concentration of Cd contained in silkworm excrement in a certain place is 0.67mg / kg, and 0.1mol / L EDTA, citric acid and acetic acid are used as extractants respectively, and the pH value is adjusted to 2 with hydrochloric acid, and then enters the electrochemical device with graphite as the electrode. After 10h electrochemical treatment, when the voltage gradient is 0.5V / cm, the removal rates of Cd in silkworm excrement are 82.0, 77.2 and 72.6% respectively; when the voltage gradient is 1.0V / cm, the removal rate of Cd in silkworm excrement The removal rates of Cd in silkworm excrement were 81.1, 75.3 and 77.2% respectively at a voltage gradient of 1.5V / cm. The concentration of remaining Cd in silkworm excrement is all lower than the limit value of 0.3mg / kg, which meets the green industry standard of foreign trade and economic cooperation of medicinal plants and preparations (green Chinese medicine standard WM / T2-2004).

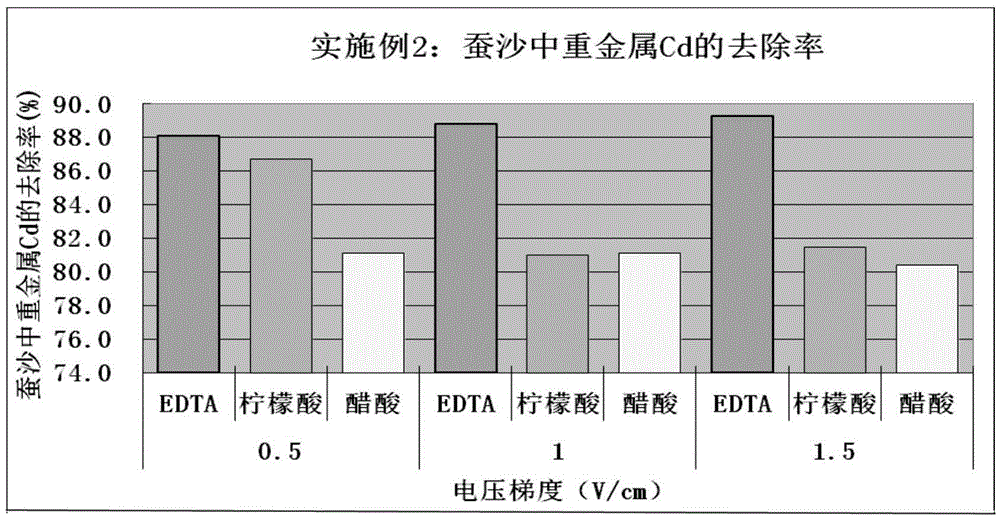

Embodiment 2

[0030] The concentration of Cd in silkworm excrement in a certain place is 1.67mg / kg, and 0.1mol / L EDTA, citric acid and acetic acid are used as extractants respectively, and after adjusting the pH value to 4 with hydrochloric acid, it enters the electrochemical device with graphite as the electrode, and the voltage gradient is 0.5~1.5V / cm, the electrode plate spacing is 14cm, after 10h electrochemical treatment, when the voltage gradient is 0.5V / cm, the removal rates of Cd in silkworm excrement are 88.1, 86.7 and 81.1%; the voltage gradient is 1.0V / cm, the removal rates of Cd in silkworm excrement were 88.8, 81.0 and 81.1%; the voltage gradient was 1.5V / cm, and the removal rates of Cd in silkworm excrement were 89.3, 81.5 and 80.4%. The concentration of remaining Cd in silkworm excrement is all lower than the limit value of 0.3mg / kg, which meets the green industry standard of foreign trade and economic cooperation of medicinal plants and preparations (green Chinese medicine s...

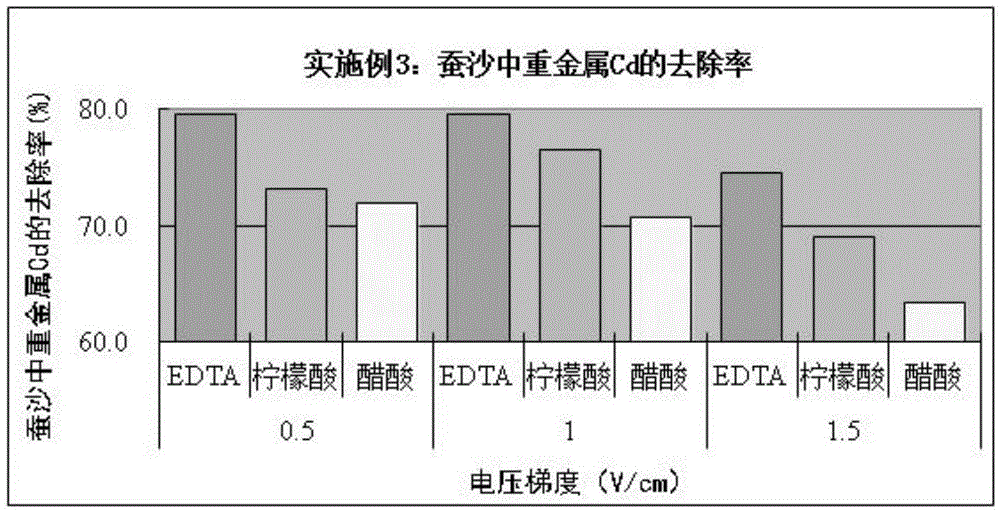

Embodiment 3

[0032] The concentration of Cd contained in silkworm excrement in a certain place is 0.67mg / kg. 0.1mol / L EDTA, citric acid and acetic acid were used as extractants respectively. After adjusting the pH value to 6 with hydrochloric acid, it entered the electrochemical device with graphite as the electrode. The spacing is 14cm, after 10h electrochemical treatment, when the voltage gradient is 0.5V / cm, the removal rates of Cd in silkworm excrement are 79.6, 73.2 and 71.9% respectively; The removal rates were 79.6, 76.6 and 70.7%; the voltage gradient was 1.5V / cm, and the removal rates of Cd in silkworm excrement were 74.5, 69.0 and 63.4%. The concentration of remaining Cd in silkworm excrement is all lower than the limit value of 0.3mg / kg, which meets the green industry standard of foreign economic and trade of medicinal plants and preparations (green Chinese medicine standard WM / T2-2004).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com