A method for multifunctional treatment of tailings

A multi-functional, tailings technology, applied in the field of solid waste resource utilization, can solve the problems of high heavy metal content, difficult ion separation, high risk, etc., and achieve the effects of short processing time, controllable reaction conditions and flexible structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: the method for the multifunctional treatment of the copper tailings is as follows:

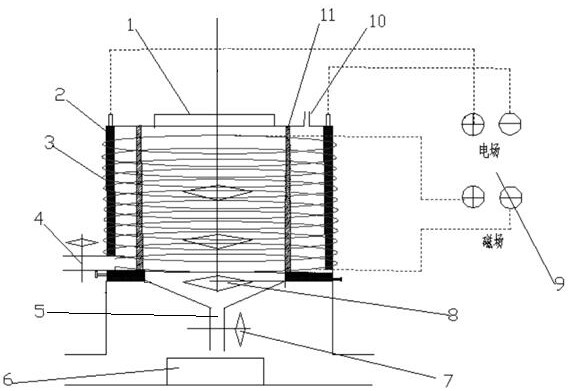

[0041] Such as figure 1 As shown, the treatment device in the method includes a treatment chamber, an anode electrode 2, a cathode electrode, an agitator 8, an antimony tailings composite film 11, and a magnetic field generator. The treatment chamber is cylindrical, and the top of the treatment chamber is provided with an inlet The material port 1 and the exhaust port 10, the anode electrode is a graphite arc electrode plate, and the cathode electrode is a stainless steel arc electrode plate; The cylindrical film is placed in the processing chamber, and the processing chamber is divided into an inner chamber and an outer chamber, the stirrer 8 is arranged in the inner chamber of the processing chamber, the magnetic field generator is arranged outside the processing chamber and the generated The magnetic field covers the processing chamber. The magnetic field generator is ...

Embodiment 2

[0054] Embodiment 2: the method for the multifunctional treatment of lead-zinc tailings is as follows:

[0055] The device used in this embodiment is the same as that in Embodiment 1, except that both the positive electrode and the negative electrode are electrode plates, and the electrode material is graphite; the number of turns of the Helmholtz coil is 100 turns;

[0056] The composition and mass percentage of antimony tailings composite film are 80% methyl acetate, 10% polyurethane, 4% ethylene glycol, 4% polyoxyethylene, and 1% antimony tailings after leaching treatment (the mass concentration of antimony tailings is Soak in 10% dilute sulfuric acid, the particle size is less than 400 mesh), 1% urea; the preparation method is as follows:

[0057] (1) Mix methyl acetate, polyurethane, ethylene glycol, polyoxyethylene, leached antimony tailings, and urea, and heat and stir in a water bath at 60°C for 8 hours;

[0058] (2) After stirring, stand still in a water bath at 40°C...

Embodiment 3

[0068] Embodiment 3: the method for the multifunctional treatment of antimony tailings is as follows:

[0069] The device used in this embodiment is the same as in Embodiment 1, except that the number of turns of the Helmholtz coil is 80 turns;

[0070] The composition and mass percentage of antimony tailings composite film are 75% methyl butanone, 12% polystyrene, 5% ethylene glycol, 4% polyoxyethylene-polyoxypropylene copolymer, antimony tailings after leaching 3% (the antimony tailings are soaked in dilute sulfuric acid with a mass concentration of 15%, and the particle size is less than 400 mesh), PVP 1%; the preparation method is as follows:

[0071] (1) Mix methyl butanone, polystyrene, ethylene glycol, polyoxyethylene-polyoxypropylene copolymer, 3% antimony tailings after leaching treatment, and PVP, and heat and stir in a water bath at 50°C for 10 hours;

[0072] (2) After the stirring is completed, stand still in a 50°C water bath until all the bubbles are eliminated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com