Equipment and combined process for treating RO concentrated solution of high-concentration organic wastewater

A technology of organic wastewater and combined process, which is applied in the field of water pollution treatment, can solve the problems of complex pollutant components, difficult treatment, and energy consumption reduction, and achieve the effects of reducing electrolysis efficiency, reducing electrolysis time, and reducing electrolysis energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

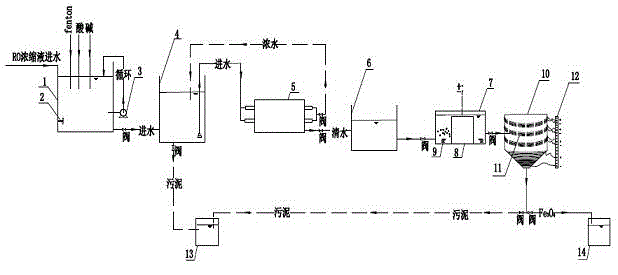

[0059] Example 1: Take the RO concentrate of the leachate treatment project of a domestic waste landfill plant in a certain place in central China as an example. The leachate treatment water volume of this project is 150m 3 / d, yields about 50 m 3 Concentrate of / d.

[0060] Use the process inlet and outlet water parameter table of the present invention:

[0061]

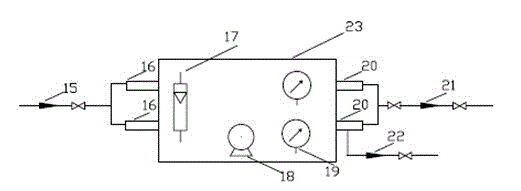

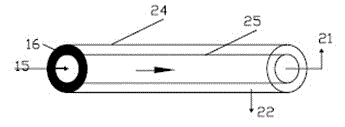

[0062] The above process flow is: Fenton pretreatment tank 1 initial water temperature 15°C, reaction time 60min; membrane system separation equipment 5 working time 35min, inlet pressure 0.095Mpa, outlet pressure 0.025Mpa, flow rate 18L / min, effluent flow rate 90L / h: m 2 ; The pulse electrolysis time in the pulse electrolysis cell 7 is 25min, the voltage is 15V, and the current density is 8 mA / ㎝ 2 , the frequency is 4K~5KHZ, the water temperature rises from 15°C to 38°C; the magnetic sedimentation tank 10 includes electromagnetic suction sedimentation, mud discharge, and drainage time for 15 minutes, an...

example 2

[0070] Example 2 Taking the RO concentrate of a coking plant in central China as an example, the water volume of RO concentrate is 80m per day 3 .

[0071] Use the process inlet and outlet water parameter table of the present invention:

[0072]

[0073] The above process flow is: Fenton pretreatment tank 1 water temperature 15°C, reaction time 60min; membrane system separation equipment 5 working time 35min, inlet pressure 0.095Mpa, outlet pressure 0.025Mpa, flow rate 18L / min, effluent flow rate 110L / h.m 2 ; The pulse electrolysis time in the pulse electrolysis cell 7 is 37min, the voltage is 15V, and the current density is 8 mA / ㎝ 2 , the frequency is 4K~5KHZ, the water temperature rises from 15°C to 37°C; the magnetic sedimentation tank 10 includes electromagnetic suction sedimentation, mud discharge, and drainage time for 15 minutes, and the external coil operating voltage is 20V.

[0074] In the above process flow, one Fenton pretreatment pool is installed, with an ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com