Method for producing metal material by composite compound

A technology for metal materials and compounds, applied in the field of preparing metal materials from composite compounds, can solve the problems of reduced mass transfer efficiency, increased energy consumption, low electrolysis efficiency and low current efficiency, and achieves improved current efficiency, reduced energy consumption, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

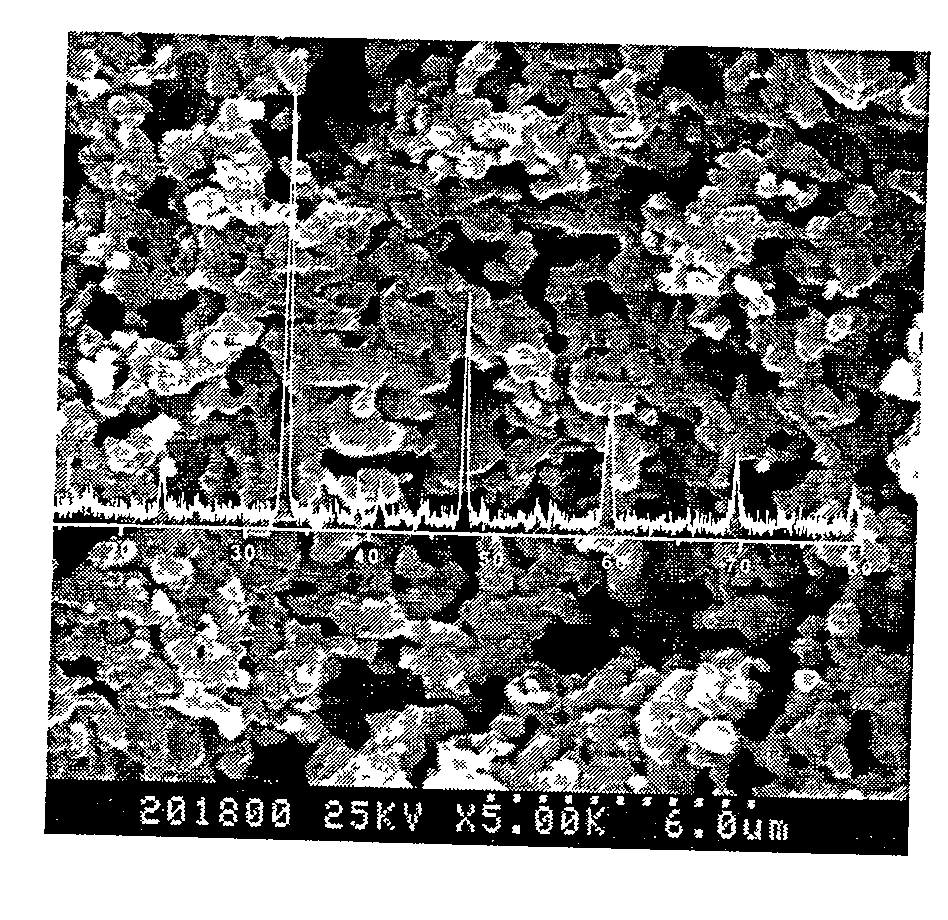

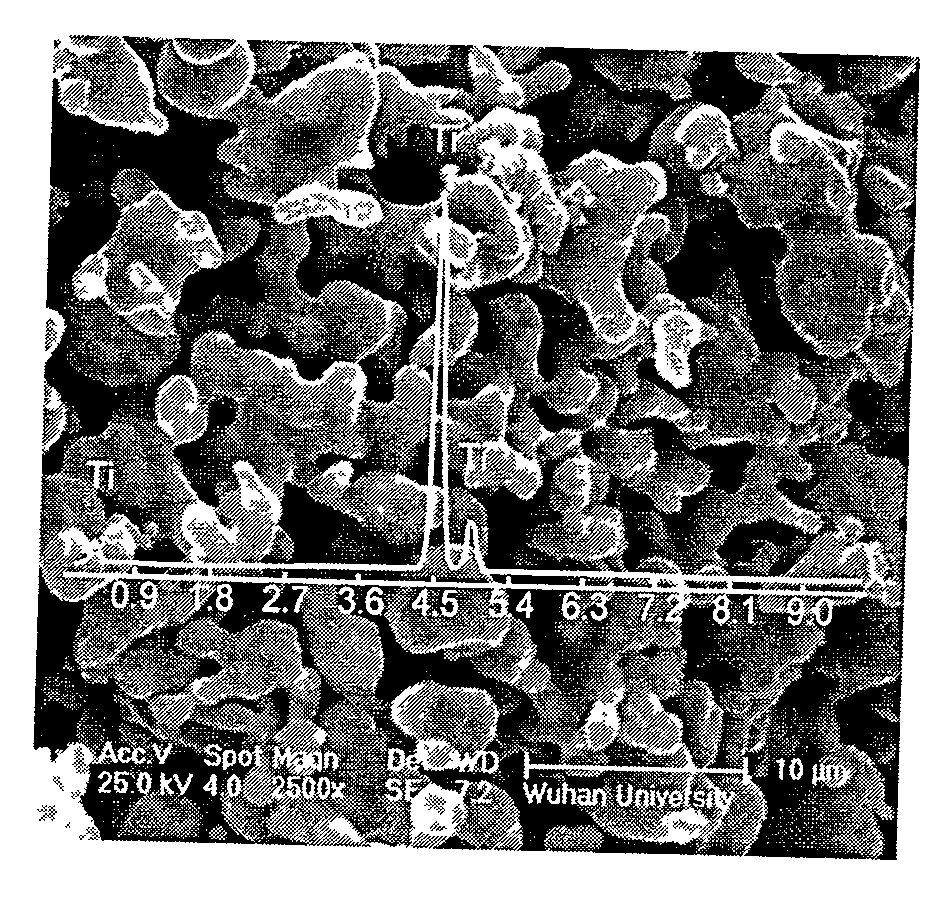

[0031] Take Ca(OH) in equimolar ratio 2 and TiO 2 , add an appropriate amount of distilled water, and use a planetary ball mill to mill for 2-5 hours at a speed of 200-300 rpm to make it fully mixed. After drying the homogeneous slurry mixture, take 2-3g of powder and press it into tablets with a pressure of 2-10MPa. Sinter the pellet at 900-1200°C for 2-10h to obtain porous CaTiO 3 (particle size 0.5-3μm, see attached figure 1 ). CaCl at 850-950°C 2 In the molten salt, argon is used as the protective gas, and CaTiO is wrapped with Mo wire or Mo net. 3 Press the tablet as a composite cathode, use graphite as an anode, apply a voltage of 3.0V, electrolyze for 6 hours, take out the product after cooling, and wash it with water to obtain metal Ti (particle size 2-10 μm, see attached figure 2 ). Electrolysis of TiO under the same conditions 2 It takes more than 10 hours to get the same result.

Embodiment 2

[0033] Take Panzhihua Iron and Steel blast furnace slag (mainly containing Ca, Mg, Si, Ti, Fe, S, O and other elements) or titanium concentrate (mainly containing Ca, Mg, Si, Ti, V, Fe, S, O and other elements) 1.5 - 2.0g, grind it to a particle size of about 0.5-10μm, press into a tablet with 2-10MPa pressure, and then sinter at 800-1000°C for 2h. CaCl at 850-950°C 2 In the molten salt, use argon as the protective gas, wrap blast furnace slag pellets with Mo wire or Mo mesh as composite cathode, use graphite rod as anode, apply 3.0-3.2V voltage, electrolyze for 6-15h, take out the product after cooling and wash with water , TiFeSi alloy powder (particle size about 10-20 μm) can be obtained.

Embodiment 3

[0035] Take fine spar (CaNaTa 2 o 6 (OH)) 100g, put it in a planetary ball mill, grind it through a 300 mesh sieve, take a 2g sample and press it with 6MPa, sinter it at 900°C for 2h, compound it with molybdenum mesh as the cathode, and use graphite as the anode, at 700°C CaCl 2 - Applying 2.9-3.3V voltage to electrolyze for 6 hours in NaCl molten salt, taking out the sample after cooling, and washing with water and dilute acid to obtain tantalum powder with a particle size of several hundred nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com