Method for preparing photocatalyst with high catalytic reduction activity

A photocatalyst and active technology, applied in the field of photocatalysis, can solve problems such as poor reduction ability, no high activity, strong reduction ability, persistent organic pollution, etc., and achieve easy separation, convenient reuse, and strong controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

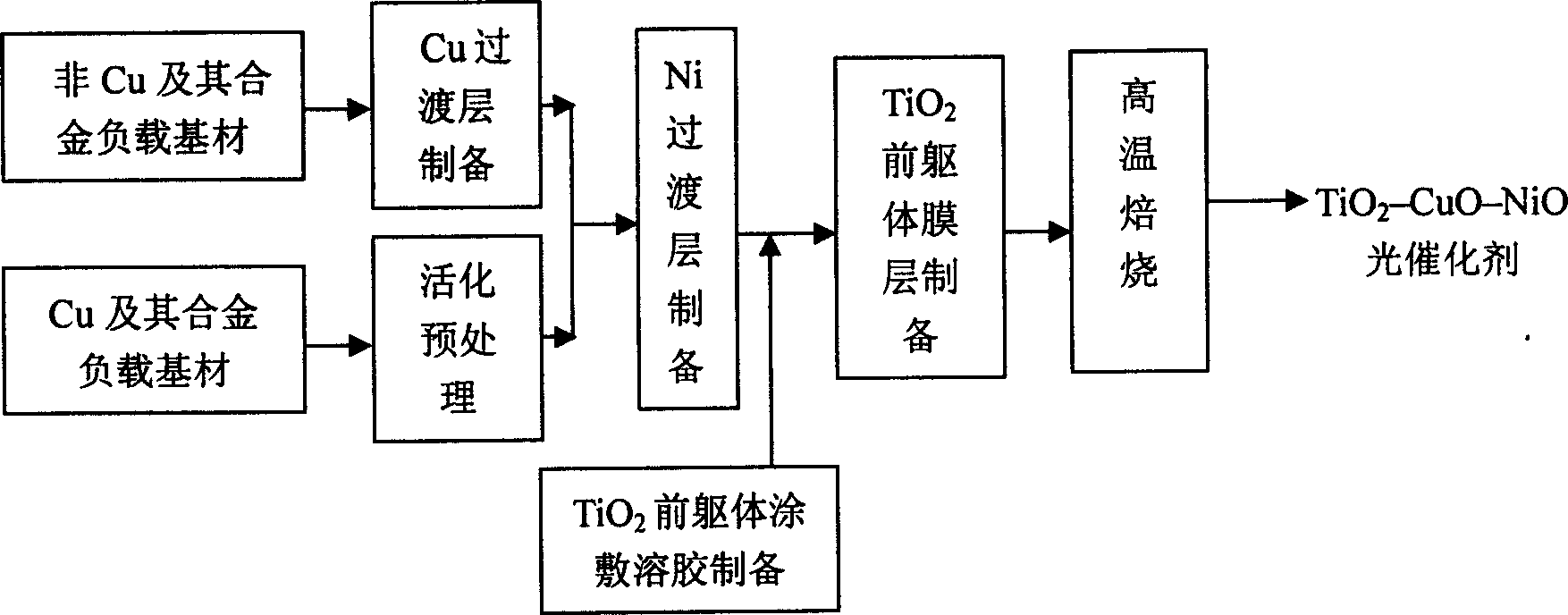

[0022] The invention provides a method for preparing a photocatalyst with high catalytic reduction activity, such as figure 1 shown, including the following steps:

[0023] 1) For pure Cu and Cu alloy loaded substrates, use acidic aqueous solution to activate pretreatment; for non-Cu and non-Cu alloy loaded substrates, perform sandblasting, thorough degreasing and cleaning pretreatment, and then load after treatment A Cu transition layer with a thickness of at least 5 μm is uniformly plated on the surface of the substrate. Among them, there are various methods of Cu plating, including chemical vapor deposition (PVD) method, physical vapor deposition (PVD) method, electrodeposited Cu plating method, and the like.

[0024] 2) Using the Ni electrodeposition process, uniformly prepare a Ni transition layer with a thickness of 30 μm to 100 μm on the surface of the prepared pure Cu and Cu alloy support substrate or the support substrate with a Cu transition layer to obtain a reduct...

Embodiment 1

[0033] Example 1: Preparation of TiO on a copper substrate 2 -CuO-NiO Thin Film Photocatalyst

[0034] 1) Put a copper sheet with a thickness of 0.4mm into 50g / L Na at 90°C 2 CO 3 Solution, wash for 30 minutes to completely remove oil. Then, at room temperature, put it in 200ml / L concentrated nitric acid aqueous solution for 20 minutes, perform activation (removal of oxide film) pretreatment, and take it out when the surface of the base material shows a uniform metallic luster. Then, rinse them thoroughly in copious amounts of deionized water and dry.

[0035] 2) Preparation of nickel electrodeposition transition layer:

[0036] First, NiSO with a mass concentration of 200g / L 4 ·7H 2 O; 10.5g / L NaCl, 35g / L H 3 BO 3 , 25g / L Na 2 SO 4 10H 2 O, 35g / L MgSO 4 ·7H 2 O is evenly mixed to obtain the plating solution required for electrodepositing nickel with a pH value of 4.0. The electroplated anode Ni plate is cleaned by detergent, and the temperature is 90 ℃ 50g / L Na ...

Embodiment 2

[0041] Example 2: Preparation of TiO on a titanium substrate 2 -CuO-NiO Thin Film Photocatalyst

[0042] 1) Pretreatment of loaded substrate and preparation of Cu transition layer:

[0043] Immerse flake industrial pure titanium with a thickness of 0.5mm in boiling Na 2 CO 3 In the solution (pH=10), keep it for 30 minutes for thorough degreasing treatment, take it out, rinse it, then immerse it in boiling 10% oxalic acid aqueous solution and keep it for 1 hour for activation treatment until the surface of the base material appears uniform dark gray After the pockmarked surface and metallic luster completely disappear, it can be taken out. After rinsing and drying, a uniform Cu transition layer with a thickness of 30 μm is prepared on the above-mentioned pretreated Ti sheet by chemical vapor deposition method, that is, CVD method.

[0044] 2) Preparation of nickel electrodeposition transition layer:

[0045] NiSO with a mass concentration of 250g / L 4 ·7H 2 O, 30g / L NiCl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com