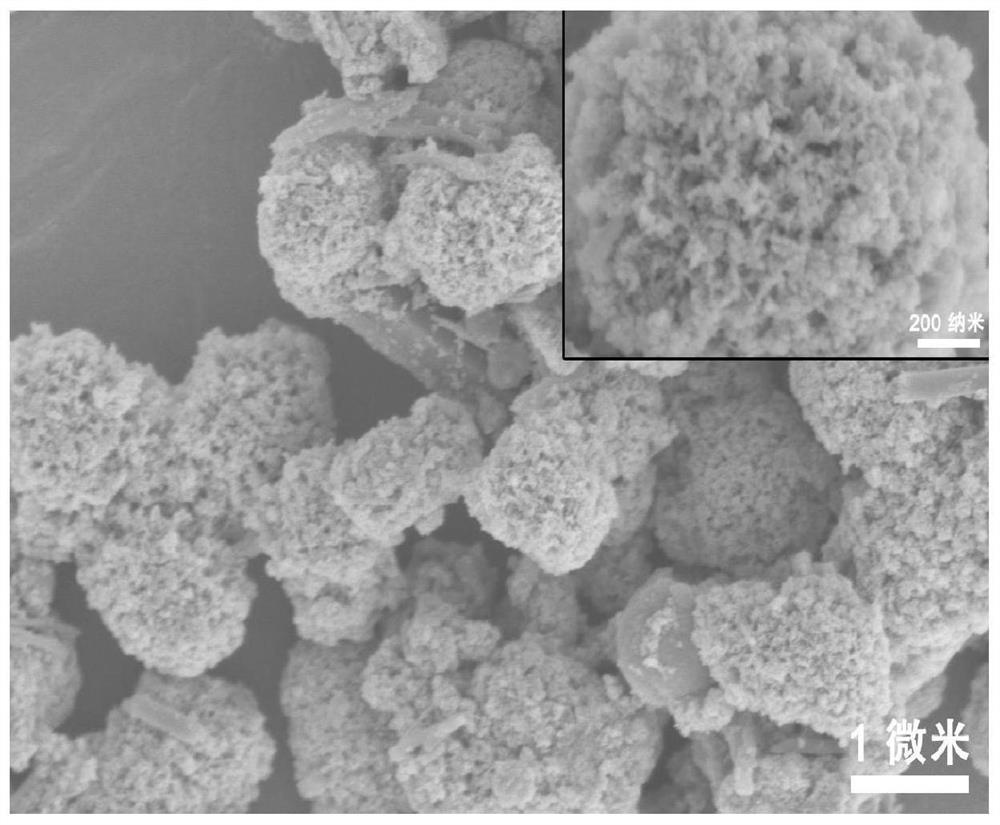

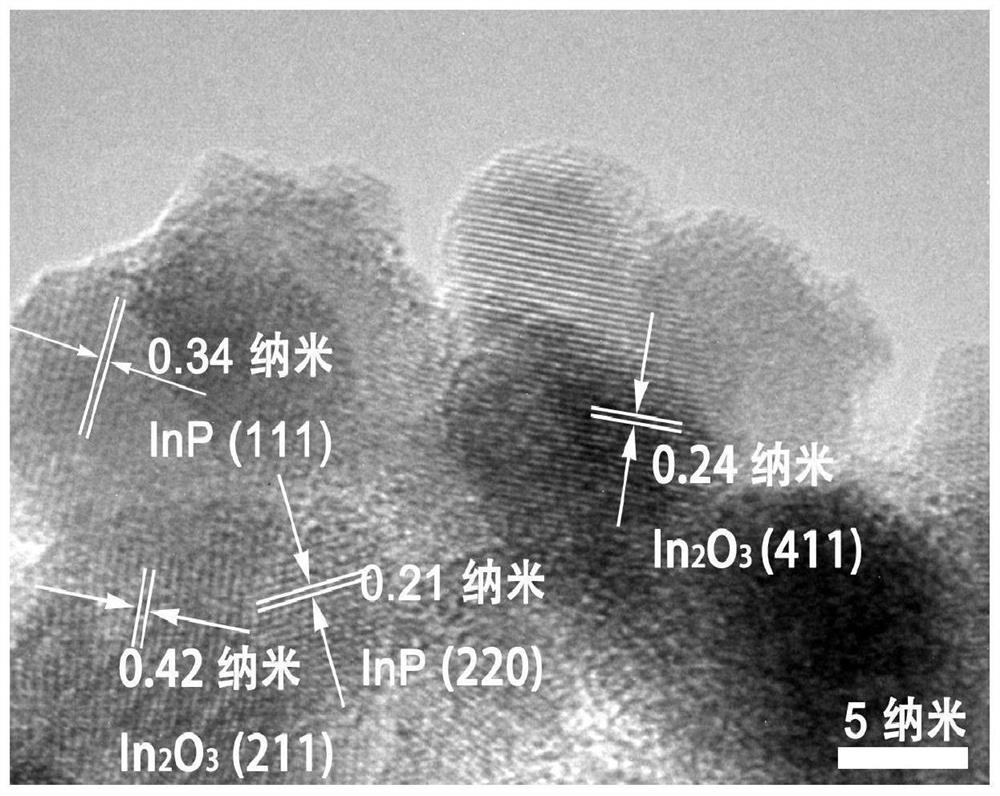

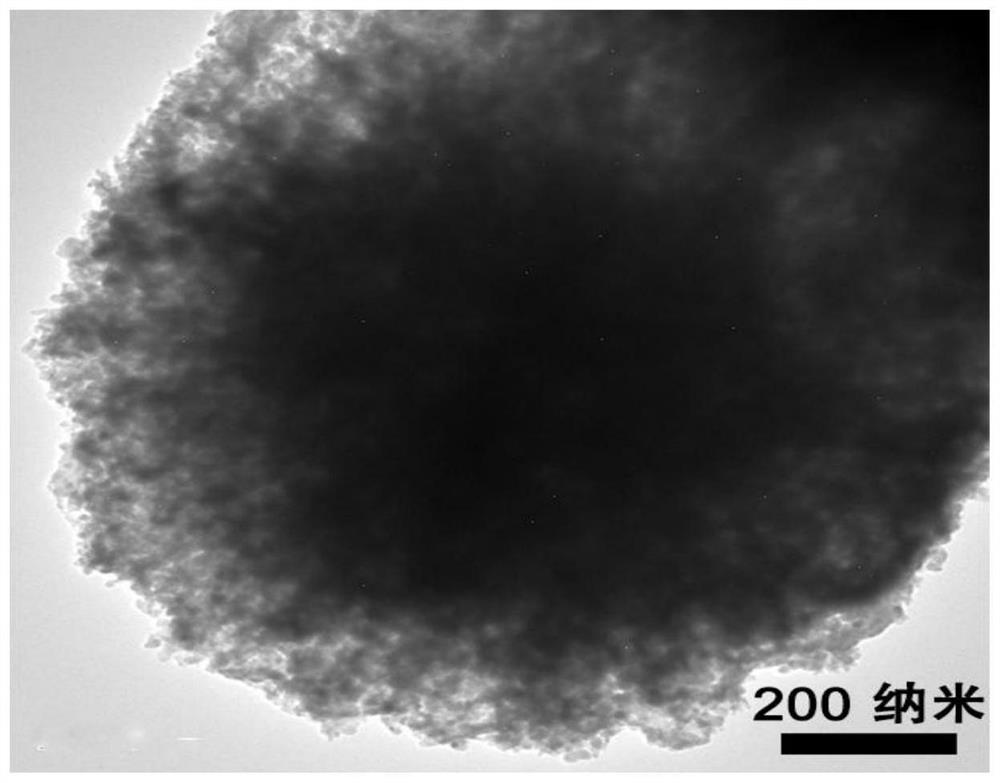

Indium phosphide-indium oxide p-n junction porous microsphere composite material as well as preparation method and application thereof

A technology of porous microspheres and composite materials, applied in the direction of carbon monoxide, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low activity, application limitations, and difficulty in separating and transferring photogenerated electrons and holes, and achieve High selectivity, accelerated transfer and transport, good carbon dioxide reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1, add tartaric acid (2mmol), indium chloride (1mmol) and L-cysteine (6mmol) separately into a 50mL Teflon-lined stainless steel autoclave for a total volume of 18mL (V 去离子水 :V 三乙烯四胺 =2:1) in a mixed solvent of deionized water and triethylenetetramine (TETA), after stirring evenly, the autoclave was sealed, and treated at 160°C in an air atmosphere for 24h, and naturally cooled to room temperature, the white precipitates were respectively Wash with deionized water and absolute ethanol, and dry in a vacuum oven to obtain InS-TETA;

[0026] Step 2: Weigh 10 mg of InS-TETA obtained in Step 1 into a 20 mL Teflon-lined stainless steel autoclave, add 12 mL of deionized water as a solvent, and keep stirring to form a uniform solution. Seal the autoclave and react at 180 °C for 10 hours in an air atmosphere to obtain a yellow precipitate, wash the precipitate with deionized water and absolute ethanol, and dry the precipitate in a vacuum oven to obtain a layered porous...

Embodiment 2

[0030] In step 1, tartaric acid (1 mmol), indium chloride (0.5 mmol) and L-cysteine (5 mmol) were added separately into a 50 mL Teflon-lined stainless steel autoclave for a total volume of 15 mL (V 去离子水 :V 三乙烯四胺 =1:1) in a mixed solvent of deionized water and triethylenetetramine (TETA), after stirring evenly, the autoclave was sealed, and treated at 140°C for 30h in an air atmosphere, and naturally cooled to room temperature, the white precipitates were respectively Wash with deionized water and absolute ethanol, and dry in a vacuum oven to obtain InS-TETA;

[0031] Step 2: Weigh 8 mg of InS-TETA obtained in Step 1 into a 20 mL Teflon-lined stainless steel autoclave, add 10 mL of deionized water as a solvent, and keep stirring to form a uniform solution. Seal the autoclave and react at 160 °C for 12 hours in an air atmosphere to obtain a yellow precipitate, wash the precipitate with deionized water and absolute ethanol, and dry the precipitate in a vacuum oven to obtain a ...

Embodiment 3

[0035] Step 1, add tartaric acid (3mmol), indium chloride (2mmol) and L-cysteine (8mmol) separately into a 50mL Teflon-lined stainless steel autoclave for a total volume of 20mL (V 去离子水 :V 三乙烯四胺 =3:2) in a mixed solvent of deionized water and triethylenetetramine (TETA), after stirring evenly, the autoclave was sealed, and treated at 180°C in an air atmosphere for 20h, and naturally cooled to room temperature, the white precipitates were respectively Wash with deionized water and absolute ethanol, and dry in a vacuum oven to obtain InS-TETA;

[0036] Step 2: Weigh 12 mg of InS-TETA obtained in Step 1 into a 20 mL Teflon-lined stainless steel autoclave, add 15 mL of deionized water as a solvent, and keep stirring to form a uniform solution. Seal the autoclave and react at 200 °C for 8 hours in an air atmosphere to obtain a yellow precipitate, wash the precipitate with deionized water and absolute ethanol, and dry the precipitate in a vacuum oven to obtain a layered porous In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com