Method for electrolytically treating high ammonia-nitrogen wastewater

An electrolytic treatment, high ammonia nitrogen technology, applied in filtration treatment, precipitation treatment, water softening and other directions, can solve the problems of excessive microorganisms, high energy consumption, high oxidant content, and achieve improved reaction activity, improved removal rate, and improved conversion. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

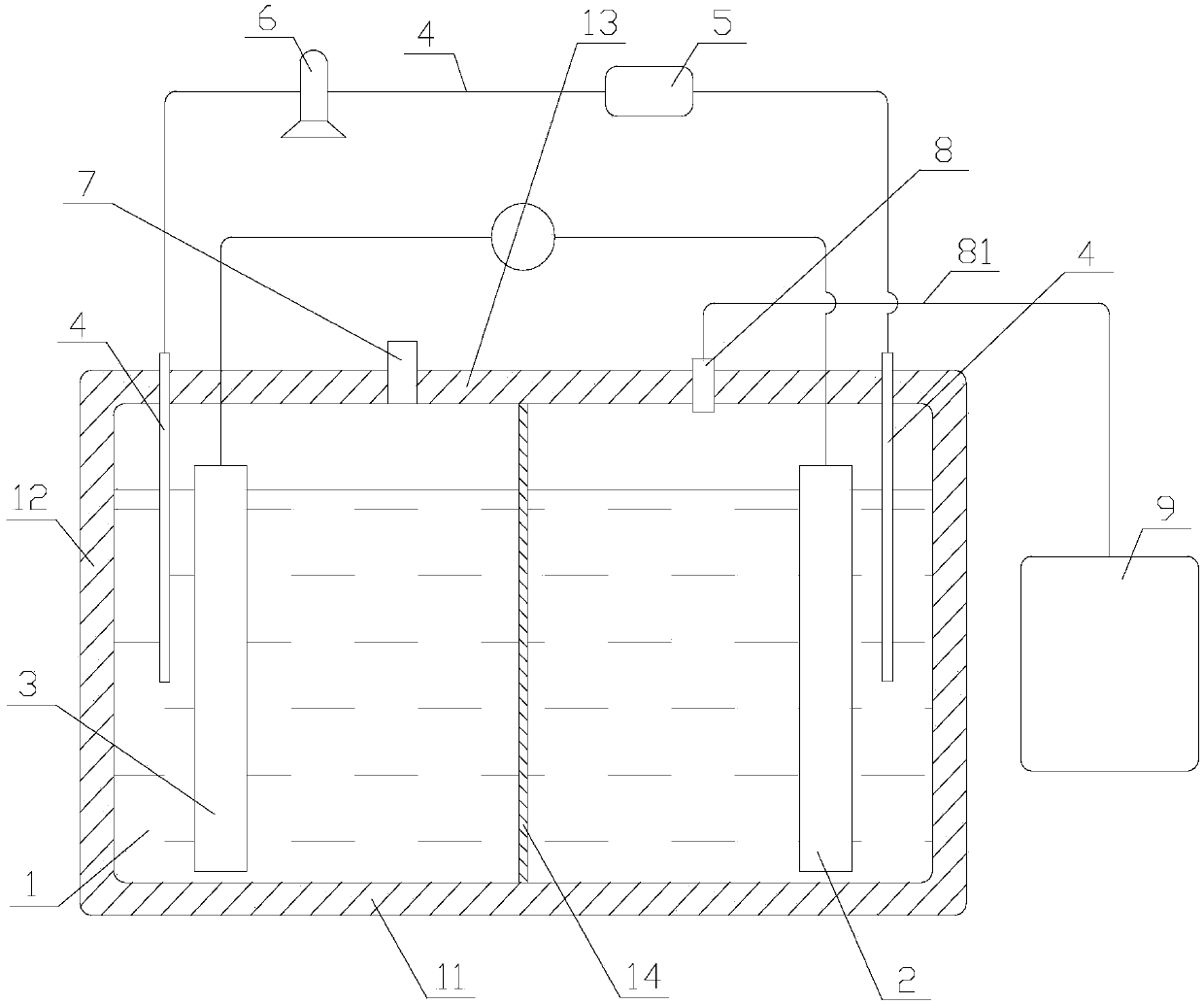

[0036] Such as figure 1 Shown, a kind of method of electrolytic treatment high ammonia nitrogen waste water of the present invention comprises the following steps:

[0037] 1) Inject high ammonia nitrogen wastewater into the electrolytic cell 1 for electrolysis;

[0038] 2) During the electrolysis process, the liquid product at the cathode 2 of the electrolytic cell 1 is drawn out, and then the liquid product is added to the anode 3 of the electrolytic cell 1 .

[0039] Wherein, in step 1), before the high ammonia nitrogen wastewater is injected into the electrolytic cell 1, carbonates are used to precipitate ions with scaling tendency in the high ammonia nitrogen wastewater, and the pH value of the high ammonia nitrogen wastewater is adjusted to alkaline.

[0040] The removal method of ions with scaling tendency in high ammonia nitrogen wastewater is:

[0041] 11) Inject the high ammonia nitrogen wastewater into the reaction tank, add sodium carbonate, and measure the pH va...

Embodiment 2

[0047] Such as figure 1 Shown, a kind of method of electrolytic treatment high ammonia nitrogen waste water of the present invention comprises the following steps:

[0048] 1) Inject high ammonia nitrogen wastewater into the electrolytic cell 1 for electrolysis;

[0049] 2) During the electrolysis process, the liquid product at the cathode 2 of the electrolytic cell 1 is drawn out, and then the liquid product is added to the anode 3 of the electrolytic cell 1 .

[0050] Wherein, in step 1), before the high ammonia nitrogen wastewater is injected into the electrolytic cell 1, carbonates are used to precipitate ions with scaling tendency in the high ammonia nitrogen wastewater, and the pH value of the high ammonia nitrogen wastewater is adjusted to alkaline.

[0051] The removal method of ions with scaling tendency in high ammonia nitrogen wastewater is:

[0052] 11) Inject the high ammonia nitrogen wastewater into the reaction tank, add sodium carbonate, and measure the pH va...

Embodiment 3

[0064] A method for electrolytic treatment of high ammonia nitrogen wastewater, comprising the following steps:

[0065] (1) high ammonia nitrogen wastewater is injected into the electrolytic cell for electrolysis;

[0066] (2) The current density in the electrolytic cell is 30-50mA / cm 2 .

[0067] Wherein, in step (1), before the high ammonia nitrogen wastewater is injected into the electrolytic cell, carbonates are used to precipitate ions with scaling tendency in the high ammonia nitrogen wastewater, and the pH value of the high ammonia nitrogen wastewater is adjusted to alkaline.

[0068] The removal method of ions with scaling tendency in high ammonia nitrogen wastewater is:

[0069] (11) Inject the high ammonia nitrogen wastewater into the reaction tank, add sodium carbonate, and measure the pH value, so that the pH value of the high ammonia nitrogen wastewater is within the scope of 8-9;

[0070] (12) Transfer the high ammonia nitrogen wastewater that precipitates to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com