Method for preparing extra high pure deuterium gas by using heavy water as raw material

A technology of deuterium gas and heavy water, applied in chemical instruments and methods, inorganic chemistry, electrolysis process, etc., can solve the problems of large evaporation and entrainment loss, affect product qualification rate, increase cost, etc., achieve stable and uniform quality, shorten electrolysis process, etc. Time, the effect of ensuring the quality of deuterium gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

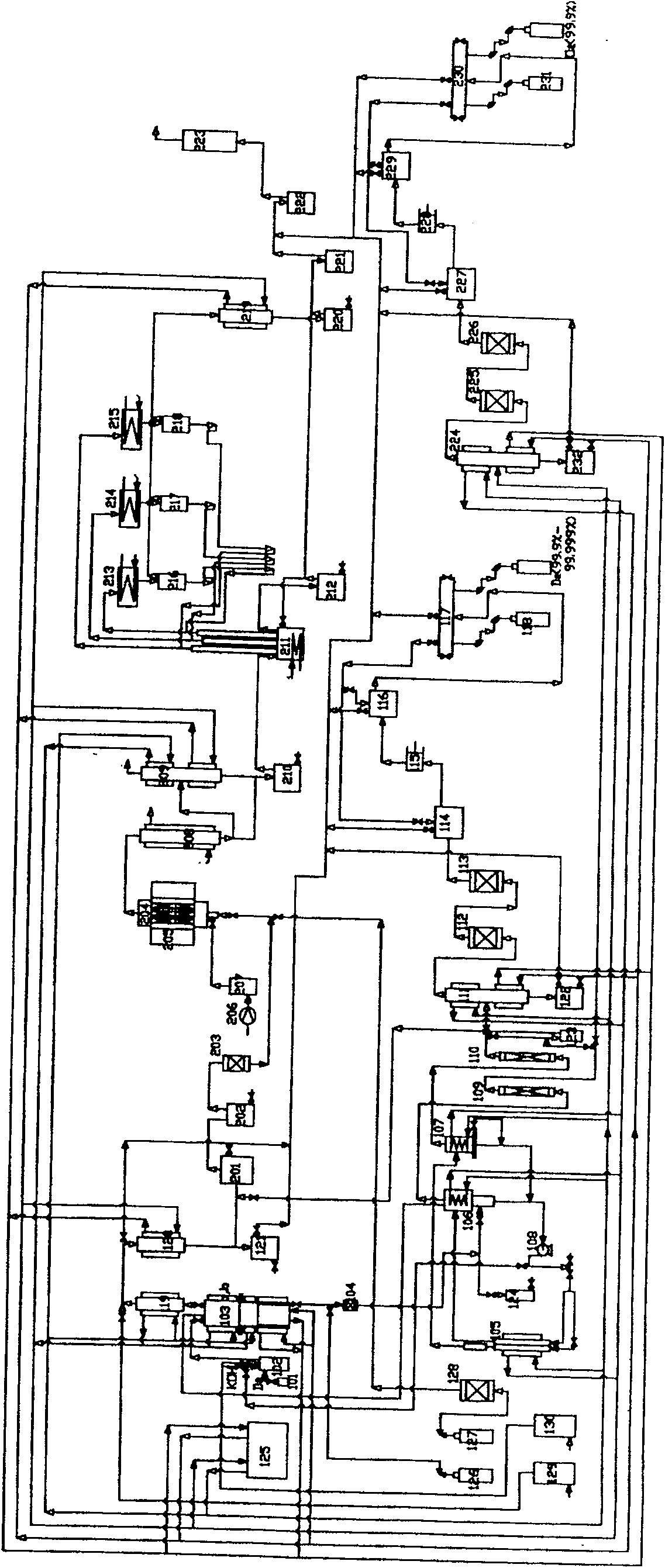

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] The production process of the present invention has two stages, the first stage is low-temperature double volume reduction to produce deuterium gas, and the second stage is detonation gas and oxygen recovery.

[0022] 1. Production of deuterium gas by double volume reduction at low temperature

[0023] Before driving, open the nitrogen cylinder (127) earlier, replace the system after the nitrogen is dried by the nitrogen drier (128), remove the air, water vapor and water film in the equipment and pipelines, and then open the high-purity nitrogen cylinder (126), Continue to replace the system to further remove the moisture film on the equipment and pipes. After the replacement is qualified, open the vacuum pump (223), vacuumize the system, remove nitrogen and residual air, water vapor and water film, and start up after passing the inspection. When driving, first ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com