Sugarcane peeling and cutting device

A cutting device and sugarcane technology, which are applied in the fields of vegetable or fruit peeling, food science, application, etc., can solve the problems of low sugarcane processing efficiency, unsatisfactory peeling effect, and poor operability, and achieve peeling effect. Better, better processing effect, better maintainability of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manner of the present invention will be described in detail below by accepting the accompanying drawings.

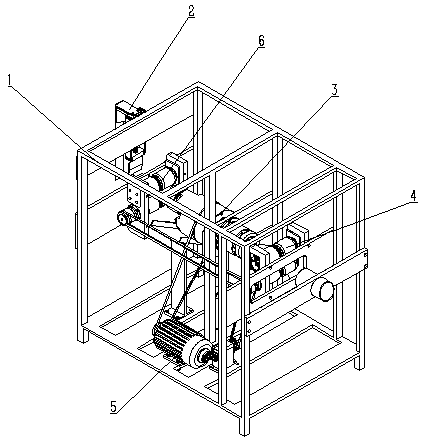

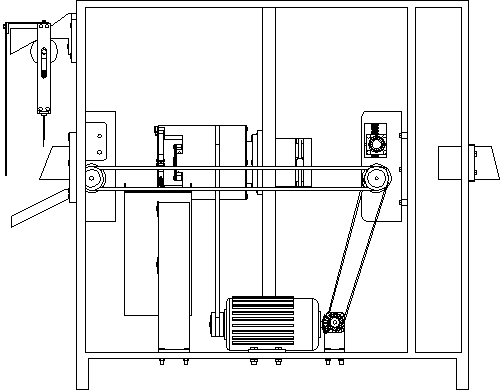

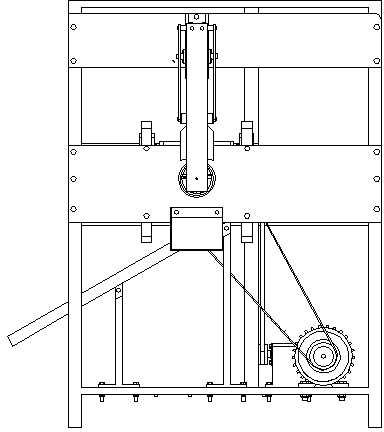

[0033] Such as Figure 1-Figure 19 Shown, a kind of sugarcane peeling and cutting device comprises frame 1, three-phase AC motor 5, feeding device 4, discharging device 6, peeling device 3 and cutting device 2, and wherein feeding device 4 mainly comprises frame 1. Feed port 401, support plate 402, fixed plate 404, driving roller 403, driven roller 406, nail teeth 413, roller support plate 405, cylindrical spiral pressure spring 412, slider 411, V-shaped pulley 410, cone Gear 408, support seat 407, V-belt 409, three-phase AC motor 5; wherein the discharge device 6 is the same as the feed device 4; wherein the peeling device 3 mainly includes a frame 1, a support plate 303, and a rotating tool holder 304 , V-shaped pulley 301, V-shaped belt 302, connecting rod 305, knife rod 306, rotary blade 307, cylindrical helical tension spring 308,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com