Peeling machine for sugarcanes

A technology of peeling machine and sugar cane, which is applied in the fields of vegetable or fruit peeling, food science, application, etc., can solve the problems of limited rotation speed of the milling cutter, unable to peel the sugar cane normally, and difficult to deal with the outer skin, etc. Stable structure, peeling and clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

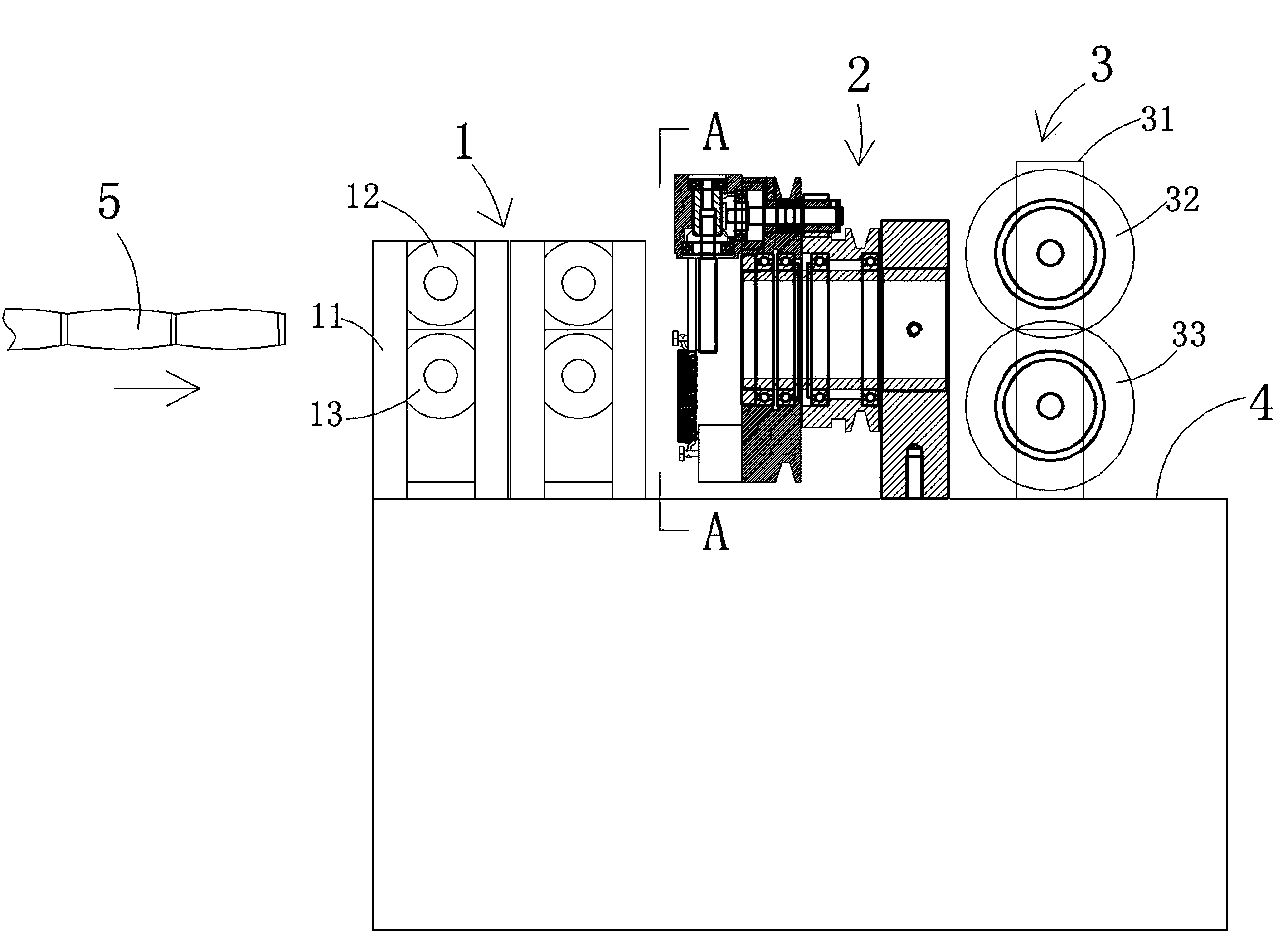

[0019] Such as figure 1 As shown, the sugarcane peeler of the present invention can be divided into sugarcane transmission mechanism 1, peeling mechanism 2 and scrubbing mechanism 3 according to functions, and the three are installed on a cabinet 4. The sugarcane 5 is transmitted to the peeling mechanism 2 by the transmission mechanism 1, and comes out from the scrubbing mechanism 3 after being peeled by the peeling mechanism 2, and the peeling and scrubbing work of the sugarcane 5 is automatically completed.

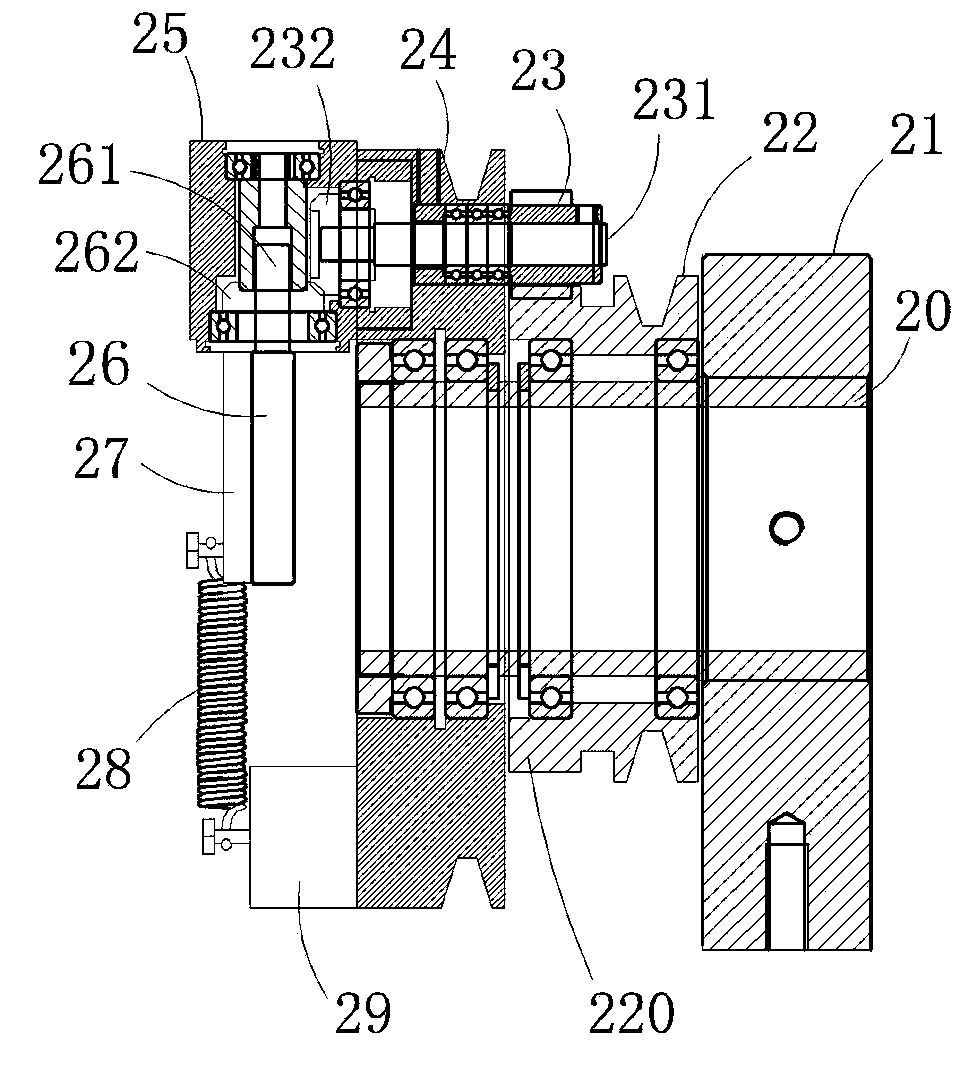

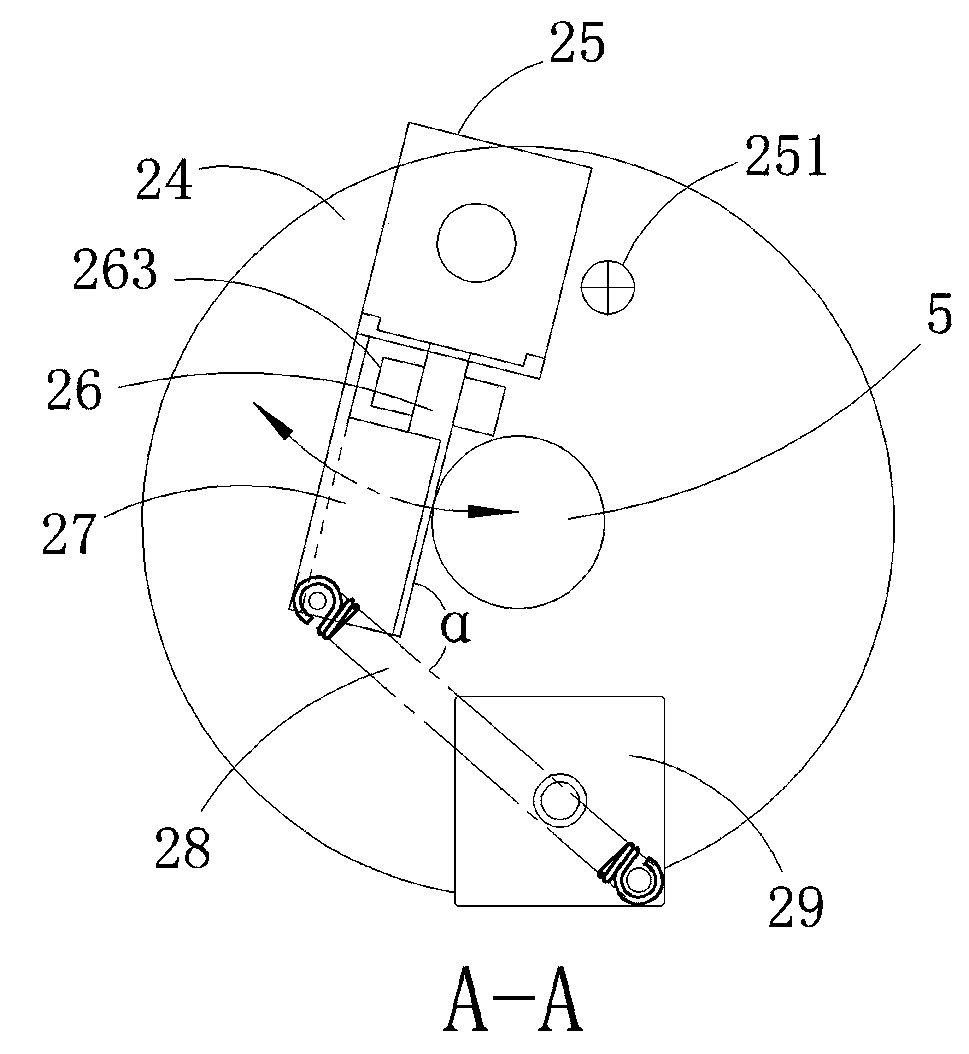

[0020] Peeling mechanism 2 includes cylindrical spiral milling cutter 26, knife seat 25 and main belt pulley 24, as figure 2 and image 3 As shown, the cutter shaft 261 of the helical milling cutter 26 is installed on the tool seat 25 through a bearing, and the tool seat 25 is installed on one side of the main belt pulley 24 through the rotating shaft 231, specifically the side facing the feeding direction. The main belt pulley 24 The shaft sleeve 20 is fixedly mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com