Automatic sugarcane peeling and cutting machine

A cutting machine and technology of sugar cane, applied in the fields of vegetable or fruit peeling, metal processing, food science, etc. Uniform skin thickness and high peeling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

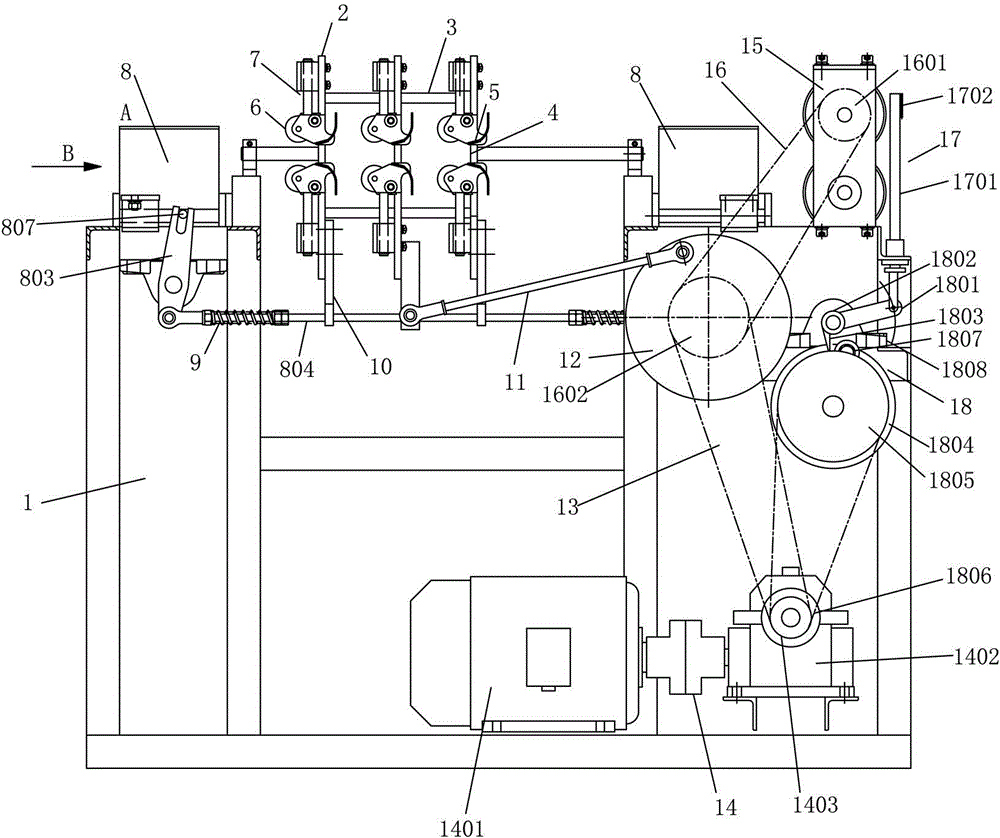

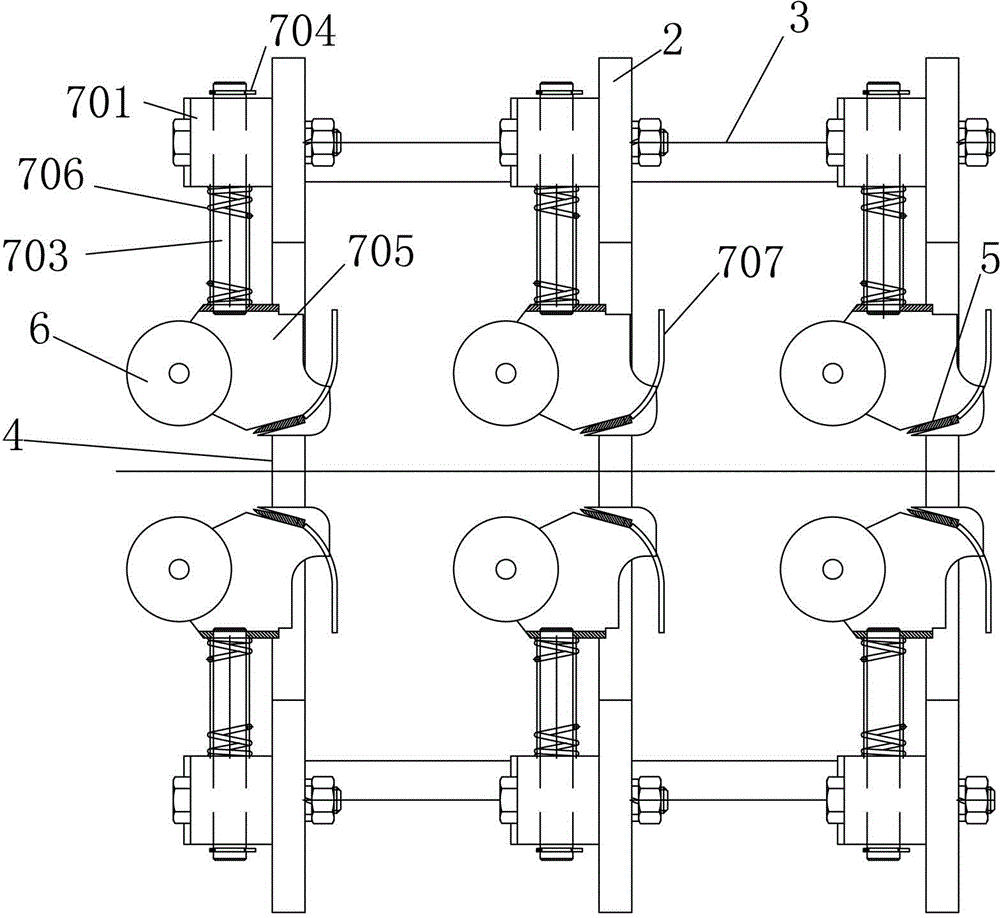

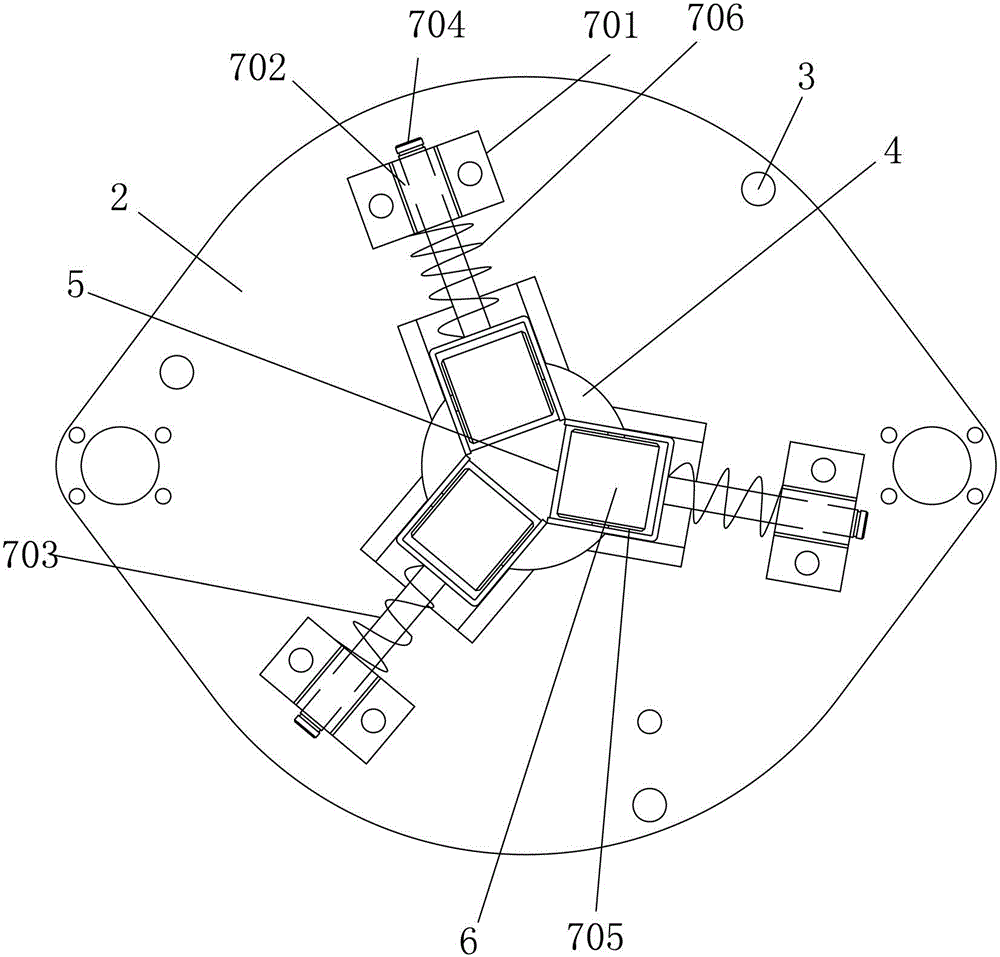

[0014] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0015] Such as Figure 1 to Figure 8 As shown, the present invention includes a frame 1, on which a plurality of knife rests 2 are horizontally spaced apart, and the knife rests 2 are horizontally slid and fixed on the frame 1, and a plurality of knife rests 2 are connected via a plurality of connecting shafts 3 , knife rest 2 central positions are provided with sugarcane passing hole 4, and knife rest 2 is provided with a plurality of peeling blades 5 that are evenly distributed around sugarcane passing hole 4 circumferences on the side perpendicular to sugarcane feed direction, and the peeling blade 5 The blade is offset toward the sugarcane import direction, and the peeling blades 5 on the plurality of knife holders 2 are arranged in a staggered manner. The knife holder 2 on the side where the peeling blades 5 are fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com