Automatic grapefruit peeling and juicing machine

A juicer, automatic technology, applied in the peeling of vegetables or fruits, juice extraction, food science, etc., can solve the problems of grapefruit peel waste, increased pollution opportunities, unfavorable grapefruit peel full utilization, etc., to increase production and reduce Evaporation and quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

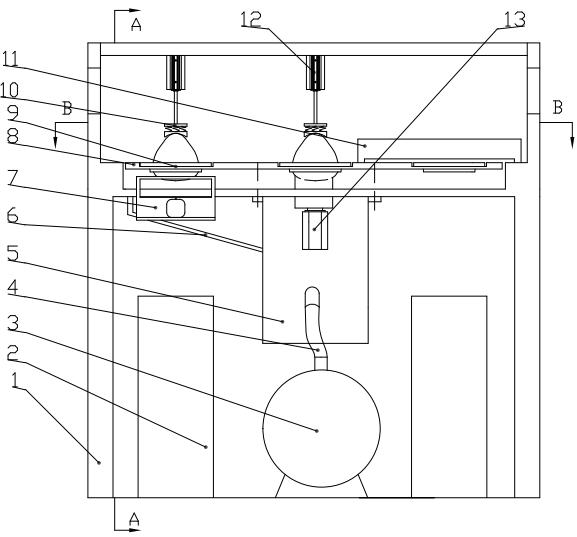

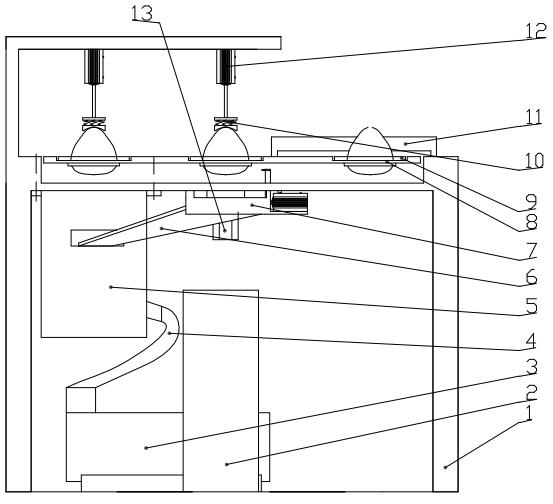

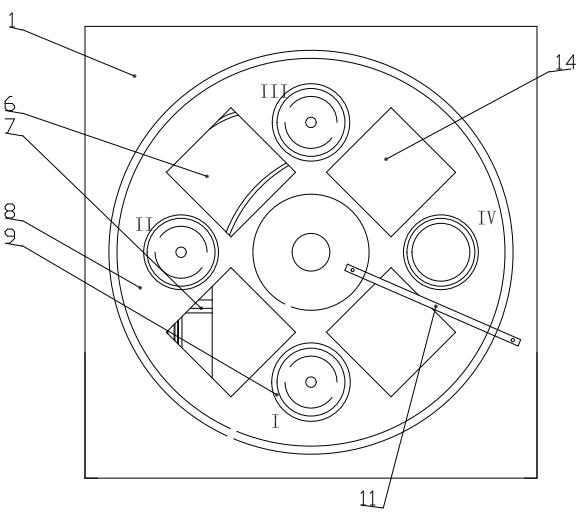

[0019] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0020] Such as Figure 1 to Figure 3 As shown, the upper part of the frame 1 of the pomelo automatic peeling juicer of the present invention is provided with a turntable 8, and four round holes are distributed on the turntable 8 in the direction of the coordinate axis of the orthogonal coordinate system, and the round holes are sleeved with Taper hole pomelo seat 9 is provided with a square hole 14 between two adjacent taper hole pomelo seats 9, and the rotating disk 8 is driven to rotate by a central motor 13. According to the average diameter of a batch of grapefruits that needs to be processed, the tapered grapefruit seat 9 can be replaced to ensure that the bottom of the grapefruit exceeds the bottom of the tapered hole grapefruit seat by 1-2 cm, which is convenient for cutting off the bottom peel; When the board is blocked, it can fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com