Reproducing method of molding sand

A technology for foundry sand and sand molds, which is applied in foundry molding equipment, machinery for cleaning/processing mold materials, and manufacturing tools, and can solve problems such as shortening the use time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

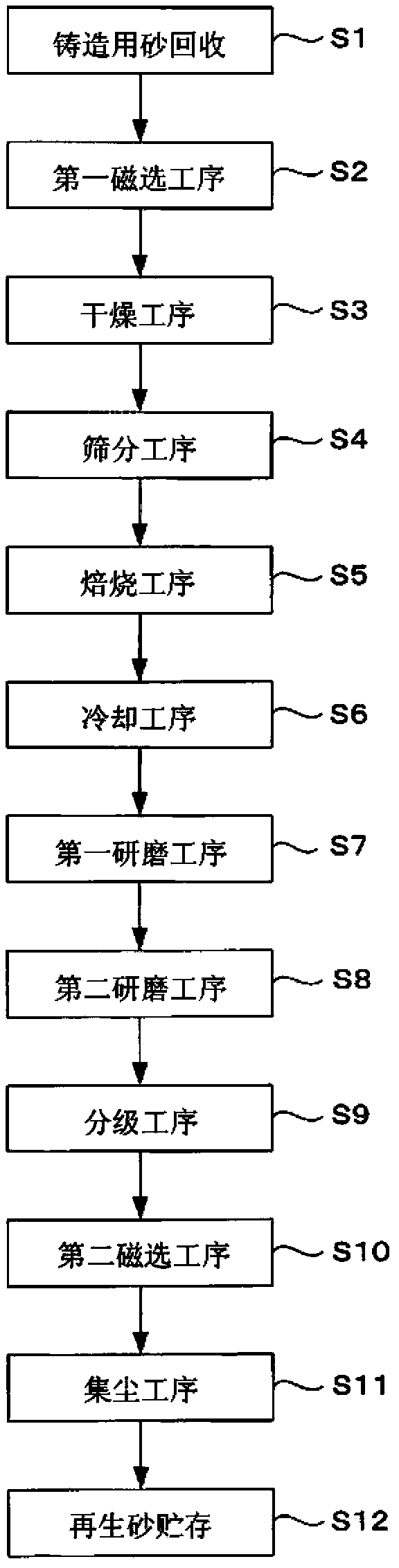

[0027] figure 1 It is a flowchart which shows the manufacturing process of the regeneration method of foundry sand which is embodiment of this invention.

[0028] Such as figure 1 As shown, in the method for regenerating foundry sand, the foundry sand that has been shaken out of the sand mold used for casting is recovered and stored in a hopper (step S1). The recovered foundry sand is mainly equivalent to the foundry sand in which the increased core sand is added in the original sand mold casting method using the main mold of the original sand mold. The core sand is foundry sand forming a core manufactured by a shell casting method, a cold box method, or a no-bake mold manufacturing method. Therefore, the recovered foundry sand is a mixture of the foundry sand forming the master mold of the original sand mold and the foundry sand forming the sand core produced by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com