Production process of dark soy sauce and the dark soy sauce

A technology of old soy sauce and production technology, which is applied in the functions of food ingredients, food science, and food ingredients as colors, etc., to achieve the effects of increasing food safety hazards, beautiful gloss, and improving red index and chromaticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

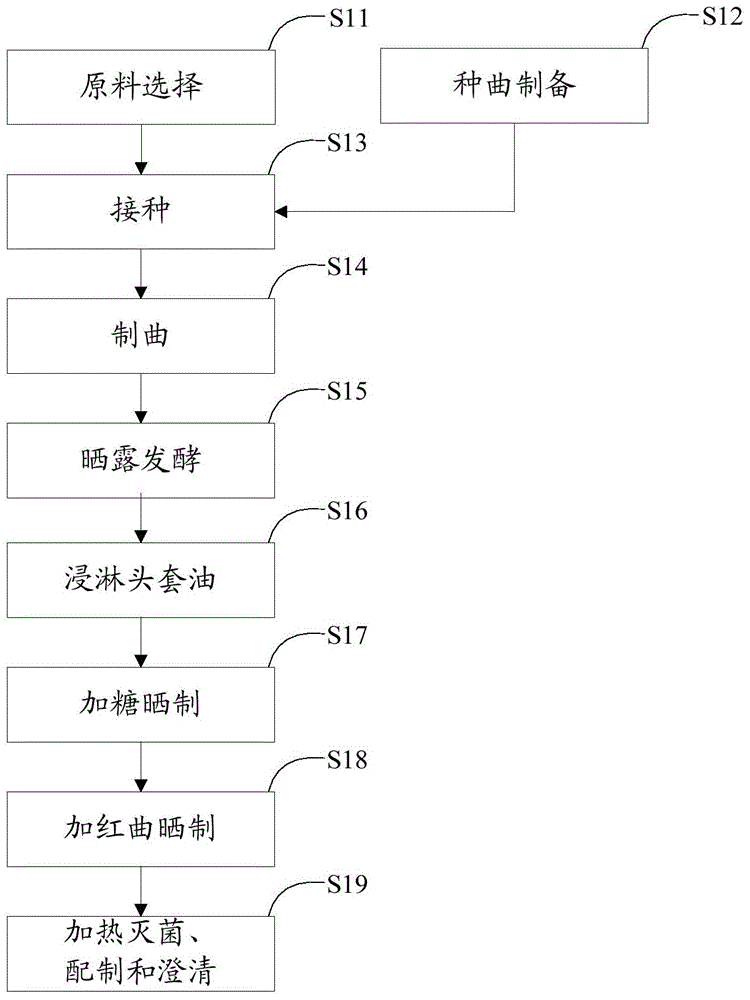

[0029] Embodiment 1, this embodiment is a preferred solution, see figure 1 As shown, the production technology of the dark soy sauce of the present embodiment comprises the following main steps:

[0030] S11. Raw material selection.

[0031] The acceptance of raw materials can be controlled according to the "Incoming Inspection and Verification Procedures for Raw Materials and Packaging Materials". Selection of suppliers: The procurement center is responsible for the evaluation, selection and control of suppliers of raw materials, auxiliary materials and packaging materials. Suppliers should have business licenses, production licenses, provide product testing or quarantine reports, and product qualification certificates. Acceptance of raw and auxiliary materials and packaging materials: the quality inspection center is responsible for formulating the inspection and acceptance standards for raw materials (soybeans must meet the requirements in Table 1.), auxiliary materials, ...

Embodiment 2

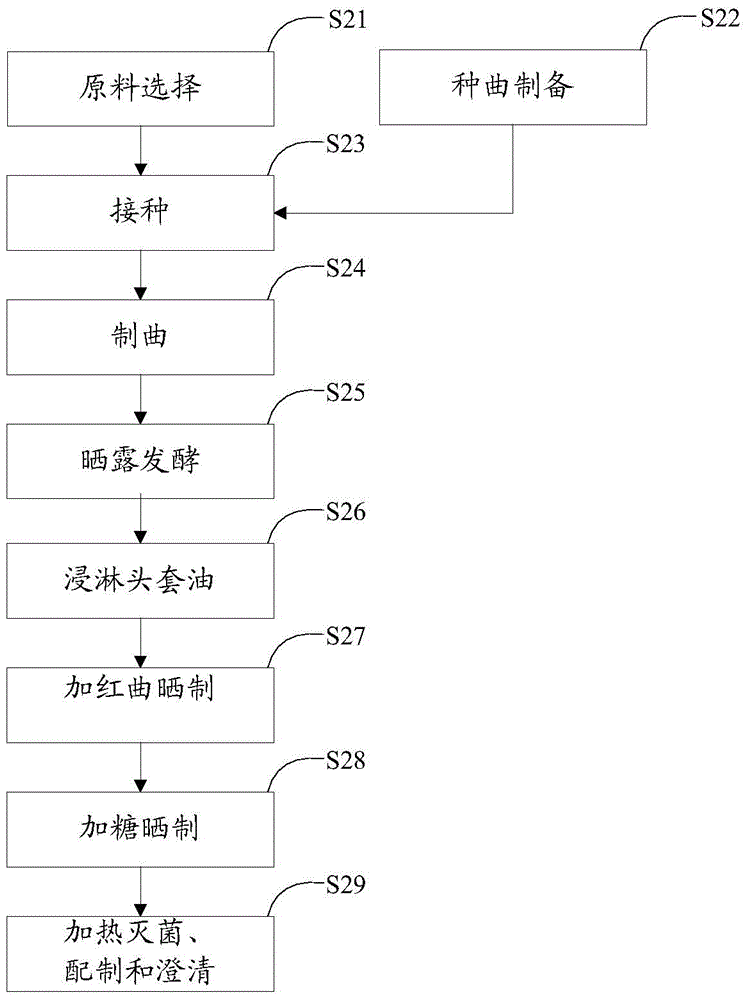

[0065] Embodiment two, see figure 2 As shown, the production technology of the dark soy sauce of the present embodiment comprises the following main steps:

[0066] S21. Raw material selection.

[0067] S22, kind of koji preparation.

[0068] S23. Vaccination.

[0069] S24, music making.

[0070] S25, sun dew fermentation.

[0071] S26, soaking headgear oil.

[0072] The above steps S21 to S26 are respectively the same as the steps S11 to S16 in the first embodiment, and will not be repeated here.

[0073] S27, add red yeast rice and dry it.

[0074] Traditional Chinese medicine believes that the functions and indications of red yeast rice are: promoting blood circulation and removing blood stasis; invigorating the spleen and eliminating food. Stagnant food and drink; distension and fullness in the abdomen; red and white diarrhea; postpartum lochia; bruises. The clinical role of red yeast rice in modern western medical research is the treatment and prevention of cardi...

Embodiment 3

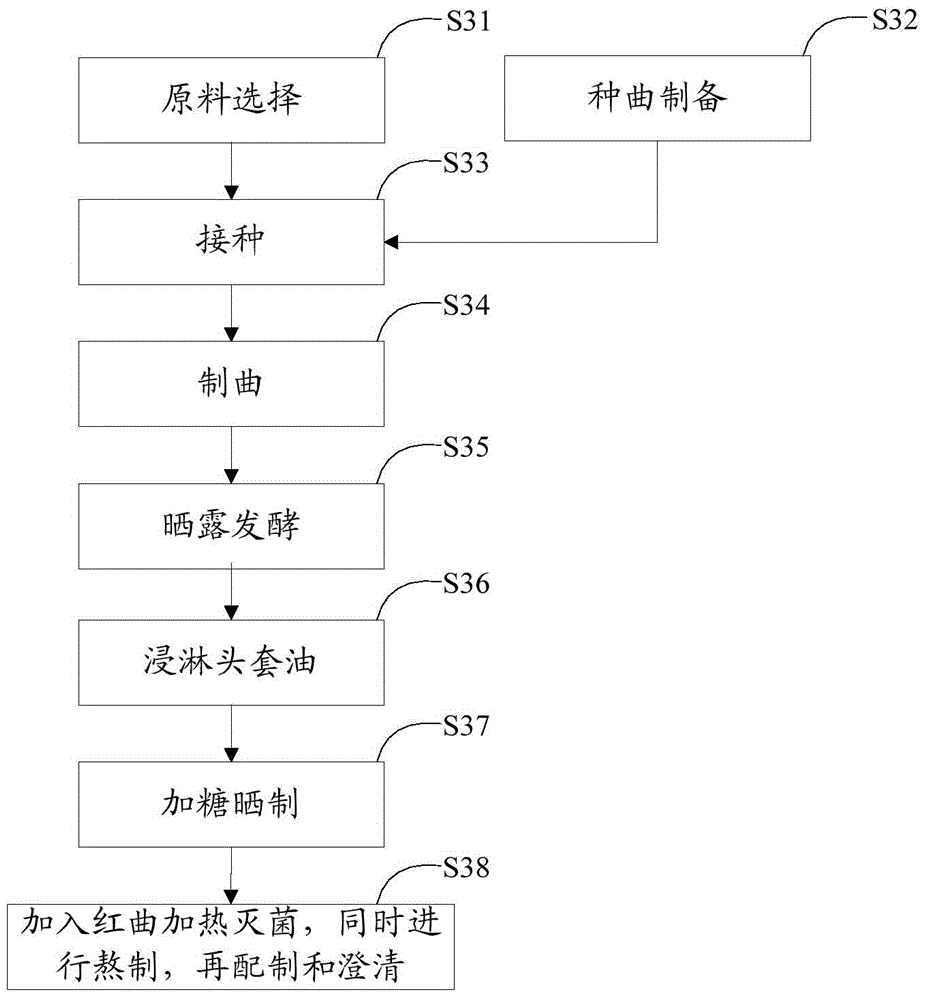

[0081] Embodiment three, refer to image 3 As shown, the production technology of the dark soy sauce of the present embodiment comprises the following main steps:

[0082] S31. Raw material selection.

[0083] S32. Preparation of koji.

[0084] S33. Vaccination.

[0085] S34, music making.

[0086] S35, sun dew fermentation.

[0087]S36, soaking headgear oil.

[0088] The above steps S31 to S36 are respectively the same as the steps S11 to S16 in the first embodiment, and will not be repeated here.

[0089] S37, adding sugar and drying.

[0090] Add appropriate proportions of white sugar, brown sugar, maltose, fructose syrup, glucose and other sugars, or combined sugars, to the leached headgear oil, and dry it for 2-3 months until the color of soy sauce reaches 2000EBC. Time prevails.

[0091] S38, add red yeast rice to heat and sterilize, boil at the same time, then prepare and clarify.

[0092] Traditional Chinese medicine believes that the functions and indications...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com