Preparation method of dark soy sauce

A technology for dark soy sauce and soy sauce, applied in the field of preparation of dark soy sauce, can solve problems such as containing 4-methylimidazole, and achieve the effects of improving utilization value, inhibiting the growth of miscellaneous bacteria, and having unique flavor and delicious taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

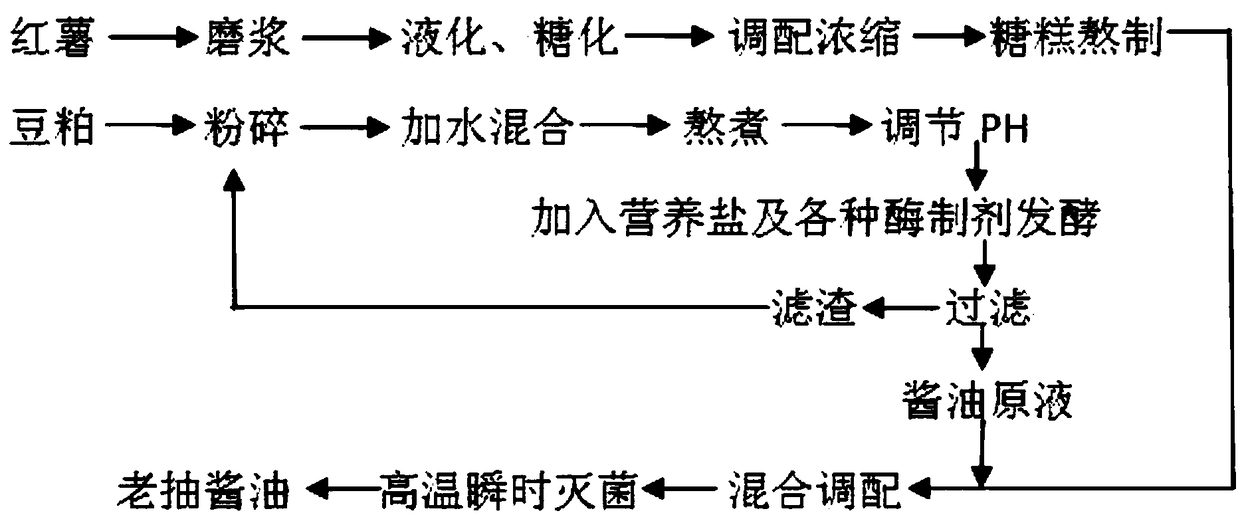

[0051] like figure 1 Shown, a kind of preparation method of dark soy sauce comprises the following steps:

[0052] 1), sugar cake preparation:

[0053] a1), raw material processing: after the sweet potato is cleaned, it is refined with a refiner, and the slurry is adjusted to pH5.5;

[0054] b1), liquefaction and saccharification: add 0.1% amylase according to the weight of sweet potatoes, heat up to 90°C for liquefaction and maintain for 40 minutes, cool to 60°C, adjust the pH to 4.5, add 0.2% glucoamylase according to the weight of sweet potatoes, saccharify for 8 hours, and the DE value reaches 55 At the end, filter the sugar solution with a plate frame to remove impurities and obtain pure sugar solution;

[0055] c1), deployment and concentration: add 80% of monosodium glutamate and 7% of edible salt to the pure sugar liquid by weight, concentrate through negative pressure at a temperature of 70°C until the DE value reaches 85, and complete the concentration to obtain co...

Embodiment 2

[0063] like figure 1 Shown, a kind of preparation method of dark soy sauce comprises the following steps:

[0064] 1), sugar cake preparation:

[0065] a1), raw material processing: after the sweet potato is cleaned, it is refined with a refiner, and the slurry is adjusted to pH5.8;

[0066] b1), liquefaction and saccharification: add 0.1% amylase according to the weight of sweet potatoes, heat up to 92°C for liquefaction and maintain for 45 minutes, cool to 62°C, adjust the pH to 4.8, add 0.2% glucoamylase according to the weight of sweet potatoes, saccharify for 10 hours, and the DE value reaches 58 At the end, filter the sugar solution with a plate frame to remove impurities and obtain pure sugar solution;

[0067] c1), deployment and concentration: add 85% monosodium glutamate and 8% edible salt to the pure sugar solution by weight, concentrate through negative pressure at a temperature of 75°C until the DE value reaches 88, and complete the concentration to obtain conce...

Embodiment 3

[0075] like figure 1 Shown, a kind of preparation method of dark soy sauce comprises the following steps:

[0076] 1), sugar cake preparation:

[0077] a1), raw material processing: after the sweet potato is cleaned, it is refined with a refiner, and the slurry is adjusted to pH6.0;

[0078] b1), liquefaction and saccharification: add 0.1% amylase according to the weight of sweet potatoes, heat up to 90°C for liquefaction and maintain for 40 minutes, cool to 60°C, adjust the pH to 4.5, add 0.2% glucoamylase according to the weight of sweet potatoes, saccharify for 8 hours, and the DE value reaches 55 At the end, filter the sugar solution with a plate frame to remove impurities and obtain pure sugar solution;

[0079] c1), deployment and concentration: add 80% of monosodium glutamate and 7% of edible salt to the pure sugar liquid by weight, concentrate through negative pressure at a temperature of 70°C until the DE value reaches 85, and complete the concentration to obtain co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com