Long-shelf-life baking-resistant eggless salad sauce and preparation method and application thereof

A technology with shelf life and baking resistance, which is applied in the field of food processing, can solve the problems of application, lack of baking resistance, etc., and achieve the effect of strong flavor, good anti-oxidation and anti-corrosion function, and good melting in the mouth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

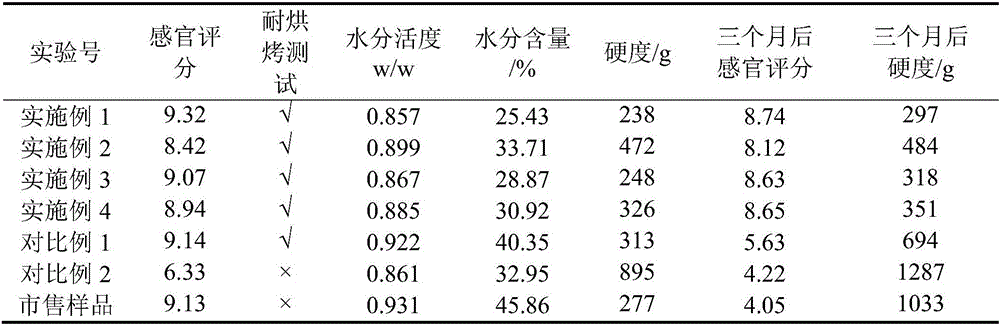

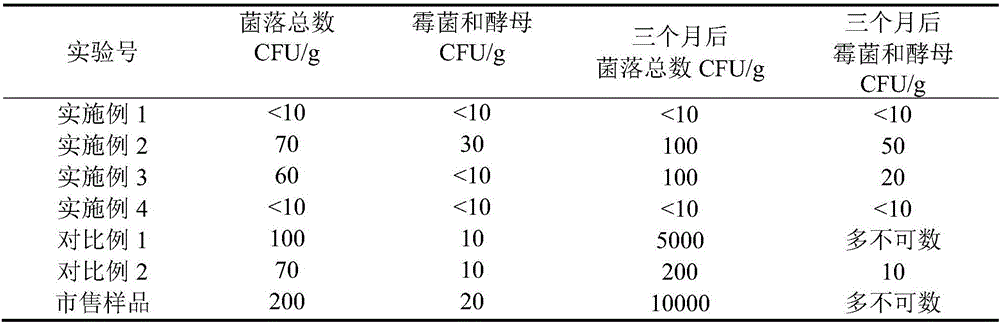

Examples

Embodiment 1

[0049] (1) 3.6kg hydroxypropyl distarch phosphate, 2kg maltodextrin (DE=15), 0.25kg sodium starch octenyl succinate, 0.5kg xanthan gum, 0.2kg locust bean gum, 0.2kg carrageenan , 0.25kg whey protein WPC70, 15kg refined granulated sugar, 0.5kg table salt, 0.1kg monosodium glutamate, 0.005kg EDTA, 0.03kg potassium sorbate, 0.3kg citric acid, 0.1kg food flavor and 0.1kg β-carotene, put into the mixing tank , and stirred with 42kg soybean oil for 10min.

[0050] (2) Pour 3kg edible glycerin, 6kg edible white vinegar (total acid is 3.5g / 100mL), 6kg sorbitol liquid (solid content is 60%), drinking water (supplemented to 100kg) into the mixing tank, and continue stirring for 10min .

[0051](3) Open the inflation valve, through the automatic inflator, the aeration coefficient is 1, the speed of the mixing head is 50rpm, the pressurization pressure is 0.5bar, and the salad dressing is inflated until the specific volume is 0.95-1.10, and then it can be packed.

Embodiment 2

[0053] (1) 5.6kg hydroxypropyl distarch phosphate, 3kg maltodextrin (DE=12), 0.15kg sodium starch octenyl succinate, 0.15kg molecularly distilled monoglyceride, 0.6kg xanthan gum, 0.15kg Locust bean gum, 0.15kg carrageenan, 0.7kg whey protein WPC70, 10kg refined castor sugar, 9.6kg glucose, 2kg salt, 0.3kg monosodium glutamate, 0.005kg EDTA, 0.016kg sodium dehydroacetate, 0.3kg malic acid, 0.3kg Edible essence and 0.1kg β-carotene are put into a mixing tank, and stirred with 20kg sunflower oil for 15 minutes.

[0054] (2) Pour 4kg of edible glycerin, 10kg of edible white vinegar (total acid is 5g / 100mL), 8kg of sorbitol liquid (solid content is 50%), and drinking water (replenish to 100kg) into the mixing tank, and continue to stir for 15min .

[0055] (3) Open the inflation valve, through the automatic inflator, the aeration coefficient is 2, the speed of the mixing head is 100rpm, and the pressurization pressure is 1bar, inflate until the specific volume of the salad dressi...

Embodiment 3

[0057] (1) 4.8kg acetylated distarch adipate, 2.5kg maltodextrin (DE=15), 0.15kg sodium starch octenyl succinate, 0.2kg xanthan gum, 0.3kg locust bean gum, 0.1kg Carrageenan, 0.5kg whey protein WPC80, 15.35kg glucose, 1kg salt, 0.2kg monosodium glutamate, 0.003kg rosemary extract, 0.002kg natamycin, 0.1kg citric acid, 0.1kg malic acid, 0.1kg food flavor and 0.00005kg tartrazine, put into a mixing tank, and stir with 35kg soybean oil for 10min until no particles are visible to the naked eye.

[0058] (2) Pour 3.5kg of edible glycerin, 7kg of edible white vinegar (total acid is 10g / 100mL), 7kg of sorbitol liquid (solid content is 70%), and drinking water (replenish to 100kg) into the mixing tank, and continue stirring for 15 minutes uniform.

[0059] (3) Open the inflation valve, through the automatic inflator, the aeration coefficient is 2, the speed of the mixing head is 50rpm, and the pressurization pressure is 1bar, inflate until the specific volume of the salad dressing is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com