Method for improving content of cubic texture of Ni9.3W base band for YBCO superconductor

A technology of cubic texture and baseband, which is applied in the field of preparation of textured baseband for YBCO superconductors, to achieve the effects of short sintering process, reduced work hardening and less impurity elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

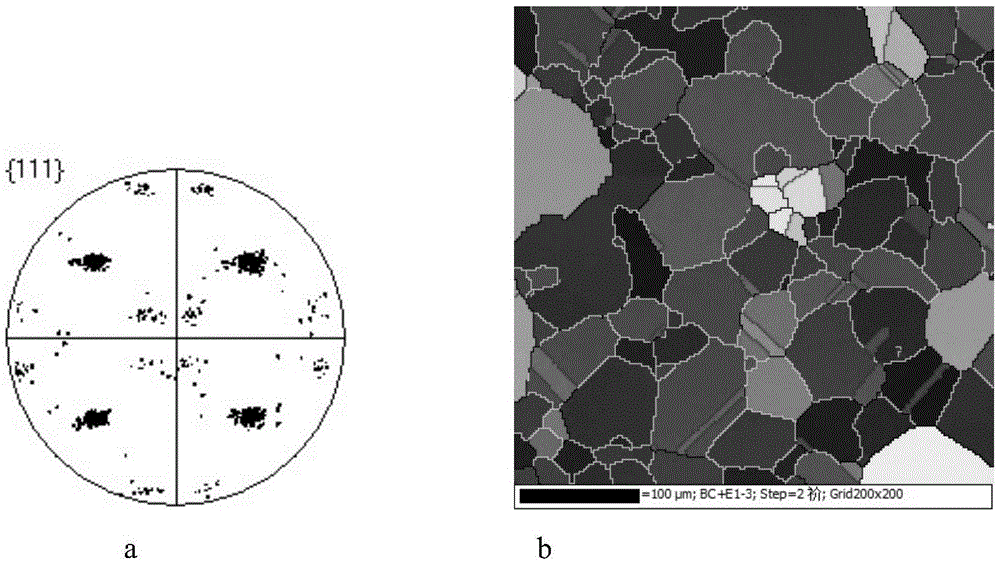

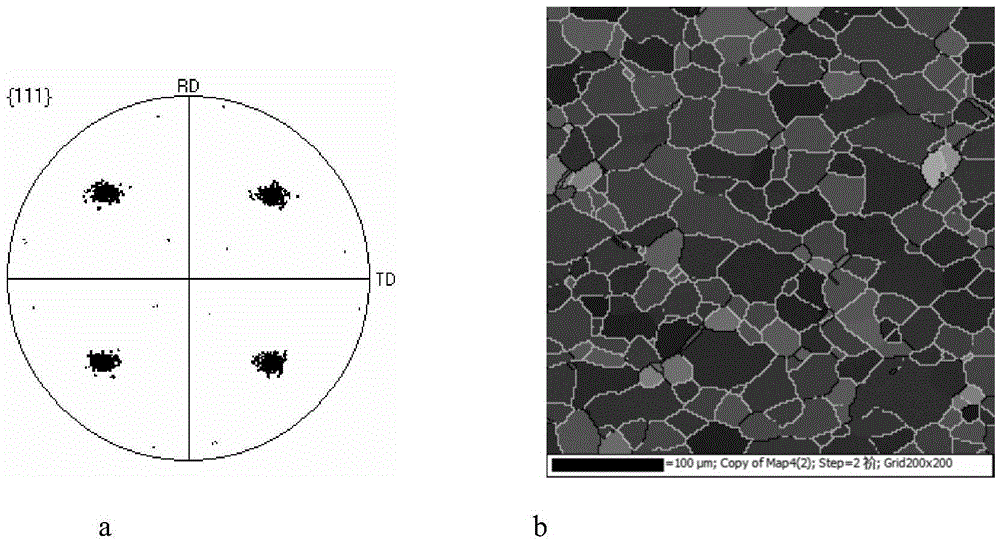

Embodiment 1

[0030] The combined method of powder metallurgy blank making + rolling intermediate heat treatment is adopted. Ni powder and W powder with an atomic percentage of 99.99% are configured into a mixed powder according to an atomic percentage of 90.7:9.3 as a raw material. After ball milling at 150rpm for 5 hours in an agate ball mill tank protected by an argon atmosphere, a uniformly mixed powder was obtained; the mixed powder obtained by ball milling was put into a graphite mold, pre-pressed with a press and left to stand for 1 hour, and then sintered by discharge plasma technology. The pre-compression pressure is 9MPa, the sintering process is always maintained at a constant pressure of 30MPa, the temperature is raised to 850°C at 100°C / min and kept for 5 minutes, and then cooled in the furnace; the obtained original billet is homogenized and annealed at 1200°C for 15 hours, and then hot-rolled at 1200°C Then get the initial billet. A billet with a thickness of 10mm was cut by...

Embodiment 2

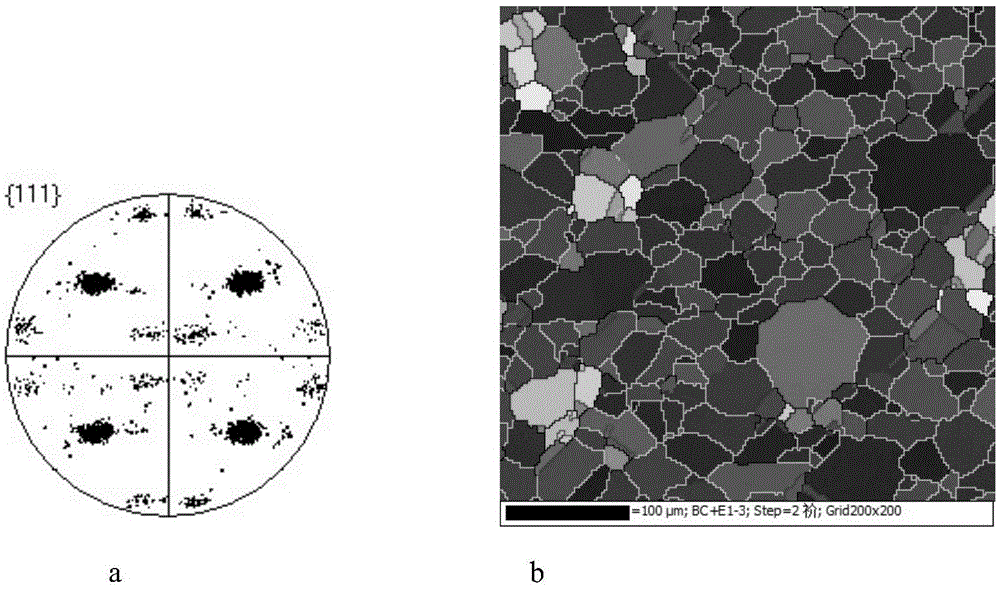

[0032] The combined method of powder metallurgy blank making + rolling intermediate heat treatment is adopted. Ni powder and W powder with an atomic percentage of 99.99% are configured into a mixed powder according to an atomic percentage of 90.7:9.3 as a raw material. After ball milling at 120rpm for 6 hours in an agate ball mill tank protected by an argon atmosphere, a uniformly mixed powder was obtained; the mixed powder obtained by ball milling was put into a graphite mold, pre-pressed with a press and left for 1.5 hours, and then sintered by discharge plasma technology , the precompression pressure is 8MPa, the sintering process is always kept at a constant pressure of 35MPa, the temperature is raised to 855°C at 90°C / min for 4min and then cooled with the furnace; the obtained original billet is homogenized at 1150°C for 24h, and then heated The initial billet is obtained after rolling. A billet with a thickness of 10 mm was cut by wire cutting as an experimental billet,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com