Method for researching alloy baseband recrystallization and cubic texture forming mechanisms through quasi in-situ electron back scattered diffraction (EBSD) technology

A quasi-in-situ, planar sample technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of repeated testing of difficult samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

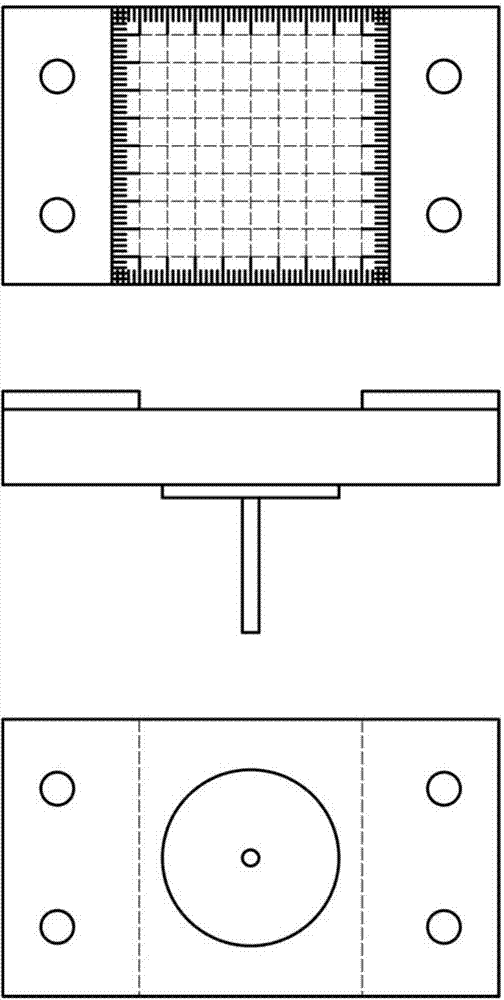

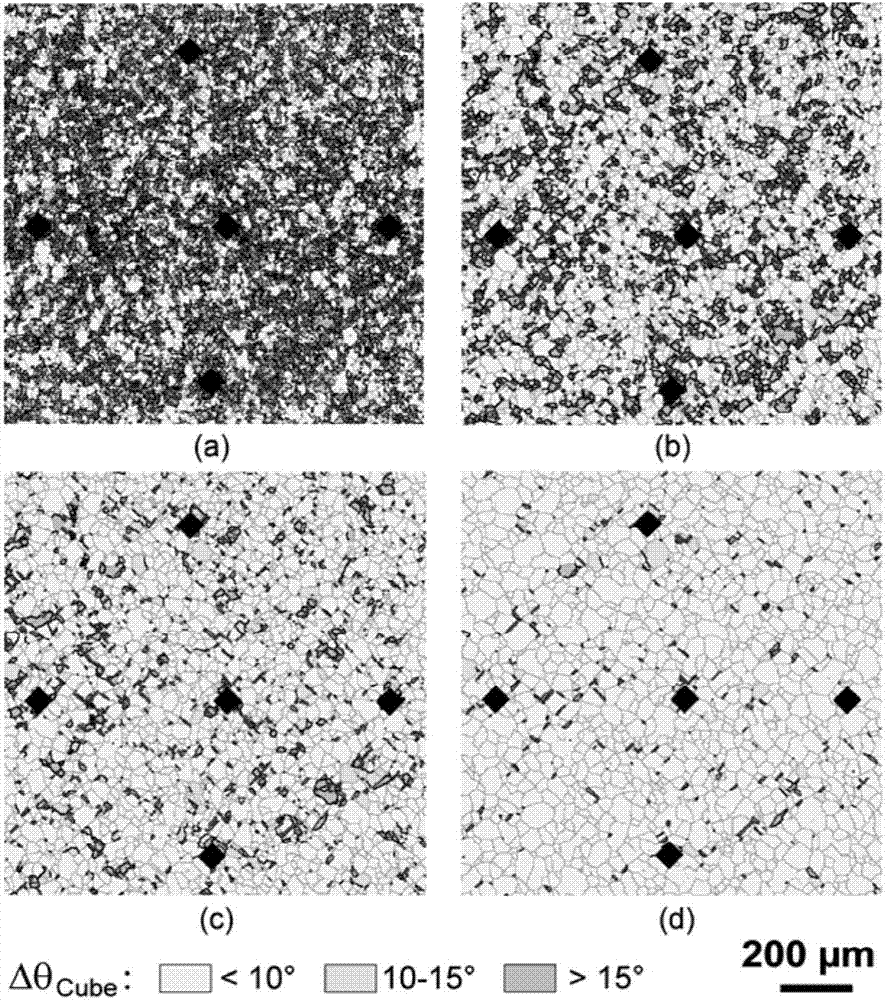

[0020] The quasi-in-situ EBSD technique was used to study the formation mechanism of strong cubic texture at high temperature for u-Ni alloy substrate. Firstly, mark the surface of the studied sample by making a hardness test; secondly, fix the studied sample on the figure 1 On the sample table shown, the EBSD test was performed on the selected area; then, the test sample was taken out, and the heat treatment time was continued to be extended at 1000°C, and the EBSD test was performed on the selected area again; the same sample was tested several times according to the experimental analysis needs Repeat the heat treatment and perform multiple EBSD tests on the same area. Select the four pictures in the quasi-in-situ EBSD test result picture, such as image 3 As shown, the method of the present invention is capable of analyzing the formation mechanism of the cubic texture.

Embodiment 2

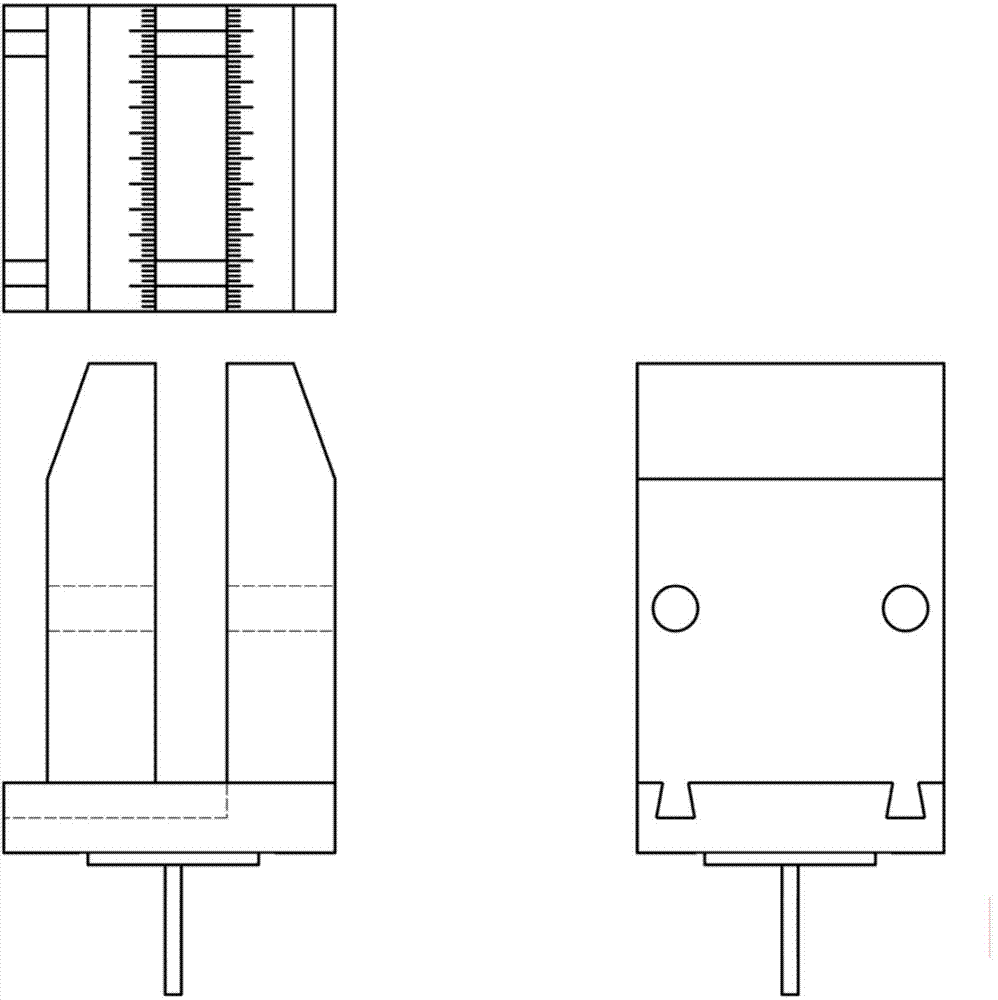

[0022] The quasi-in-situ EBSD technique was used to study the growth mechanism of recrystallized grains on Ni5W alloy substrate. Since the cross-section of the sample is only 80 μm, it is not suitable to mark the surface of the studied sample by hardness testing, so it is mainly positioned through the scale on the sample stage; first, the studied sample is heat-treated at 700 °C for 5 minutes, fixed at figure 2 On the sample stage shown, the EBSD test is performed on the selected area; then, the test sample is taken out, and the heat treatment time is continued to be extended at 700°C, and the EBSD test is performed on the selected area again. Select two pictures in the quasi-in-situ EBSD test result graph, such as Figure 4 As shown, the method of the present invention is capable of analyzing the recrystallization mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com