Method for quickly forming textures on surface of workpiece

A technology for surface texture and parts, which is applied in the field of rapid prototyping of surface texture of single/small batch parts, which can solve the problems that the final texture effect cannot be guaranteed, the forming texture is difficult to control, and the process requirements are strict, so as to achieve soft texture and quick replacement , good texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The method for rapid prototyping of the surface texture of a product of the present invention will be further described in detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

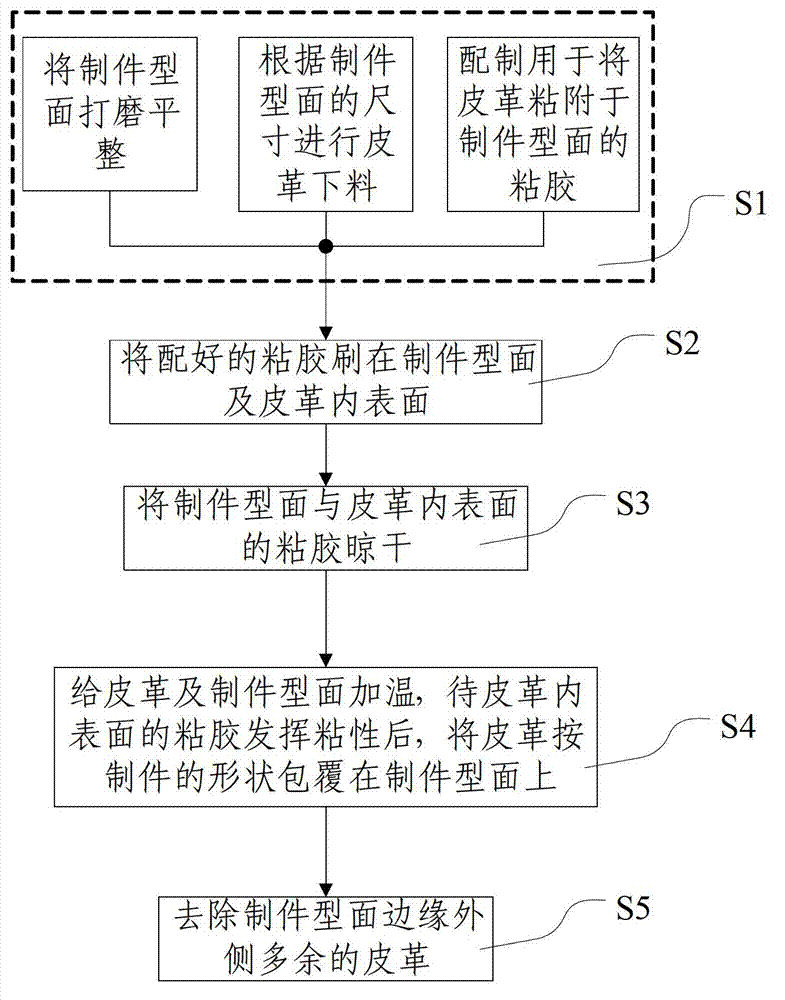

[0024] The present invention will be described below with ABS (acrylonitrile-butadiene-styrene copolymer) products as an example. Such as figure 1 As shown, a method for rapid prototyping of a workpiece surface texture of the present invention comprises the following steps:

[0025] S1. Before texture forming, preparations need to be made, including smoothing the surface of the workpiece, blanking the leather and configuring glue according to the size of the surface of the workpiece. These three tasks can be carried out in sequence, and the sequence of operations It can be adjusted, and it can also be carried out by multiple people at the same time, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com