Preparation process of double-layer texture back shell

A preparation process and texture technology, applied in the field of back shell, can solve the problems of single gradient effect and no colorful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] During concrete implementation preparation, select following technology for use,

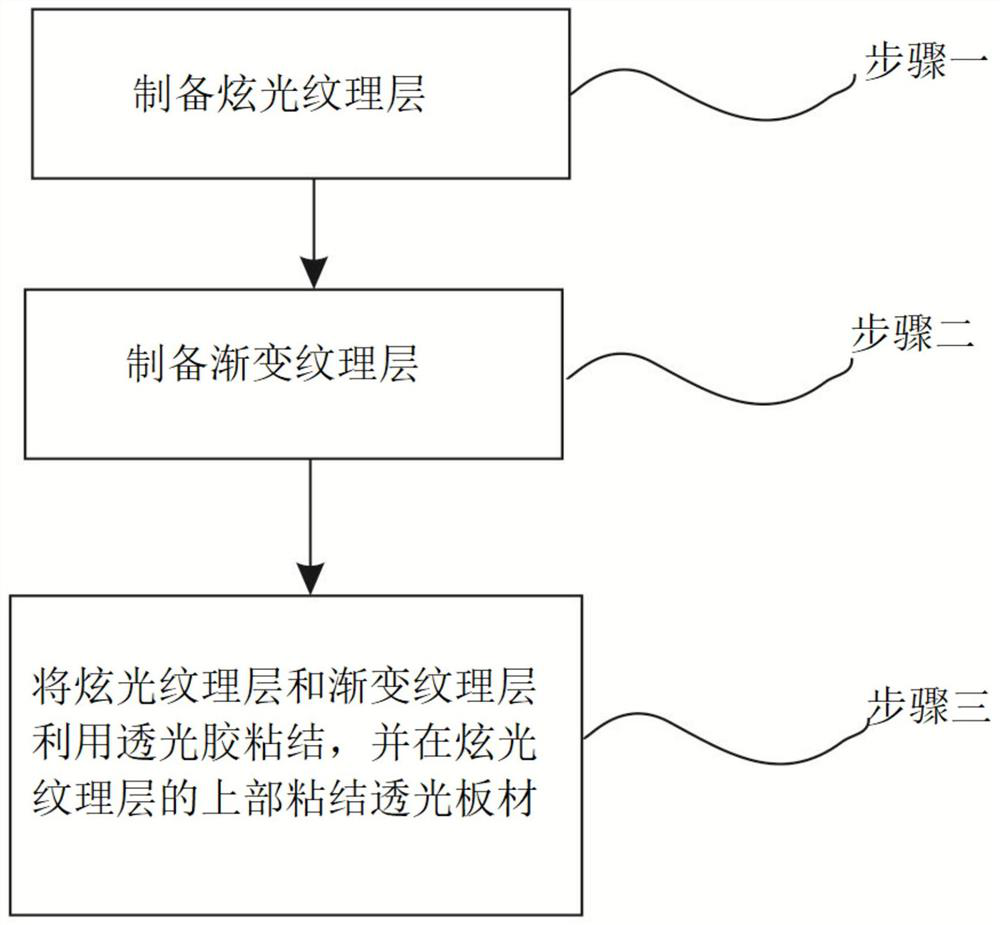

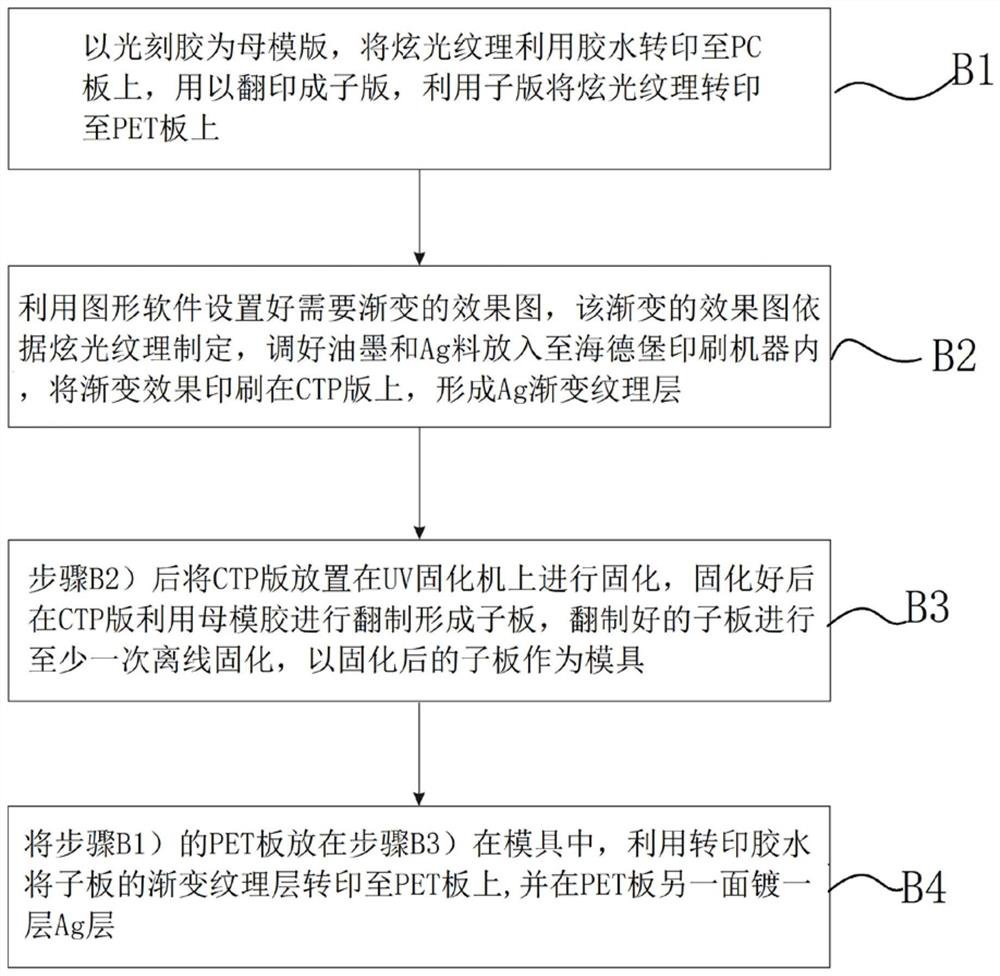

[0054] A preparation process for a double-layer textured back shell, comprising the steps of:

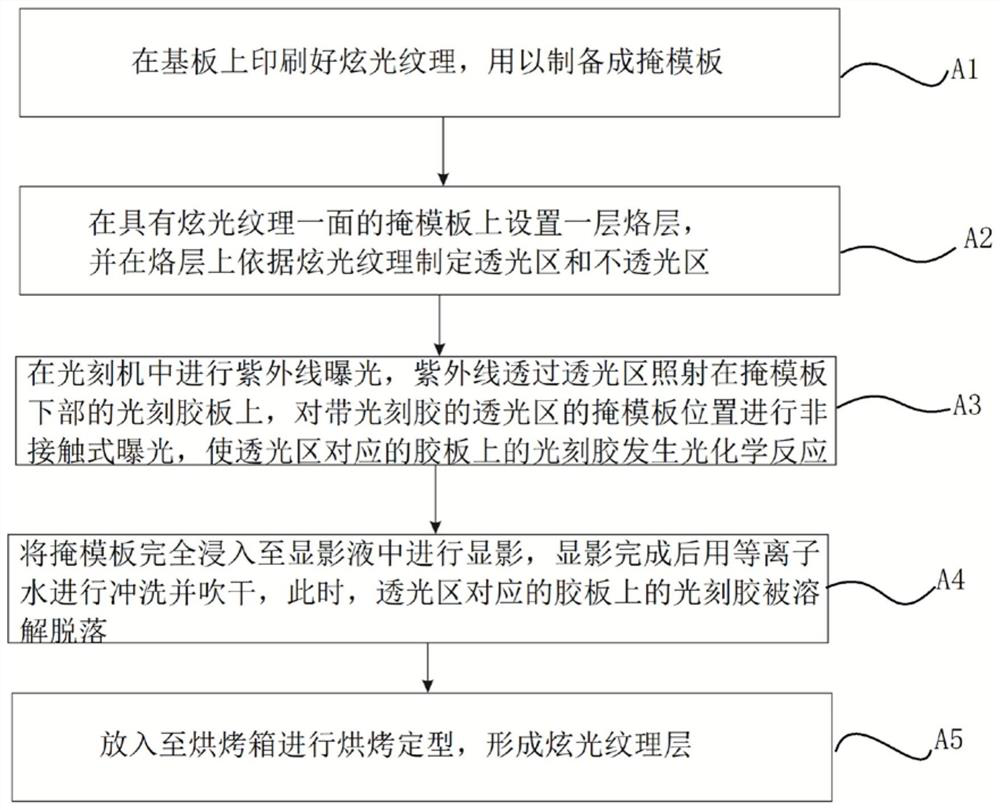

[0055] One: Prepare the glare texture layer:

[0056] A1) Select the high-transparency glare texture to draw the glare texture on the substrate, and make it into a mask. The mask is made of soda glass, and one side of the soda glass contains a chrome layer. and the opaque area, the wide line spacing is generally 0.25um-0.5um;

[0057] A2) Use a lithography machine manufactured by the Chinese Academy of Sciences for ultraviolet exposure. There is a photoresist plate under the mask (the thickness of the photoresist plate determines the depth of the texture), and the ultraviolet rays shine on the photoresist plate through the light-transmitting area. , carry out non-contact exposure to the blank mask plate with photoresist plate (that is, non-contact exposure to the position of the mask plate in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com