Texture forming equipment for artificial quartz stone plate and use method of texture forming equipment

An artificial quartz stone and texture technology, which is applied in the field of texture forming equipment for artificial quartz stone plates, can solve problems such as texture errors, reduction of device practicability, and influence of model stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

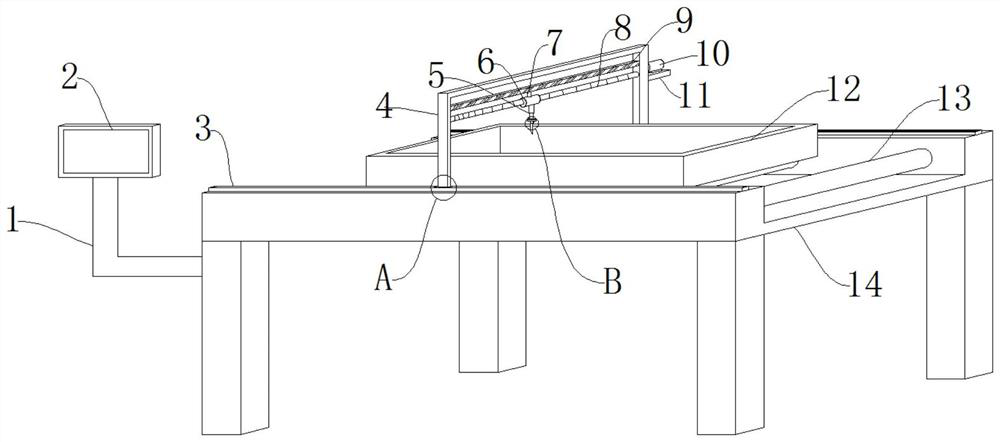

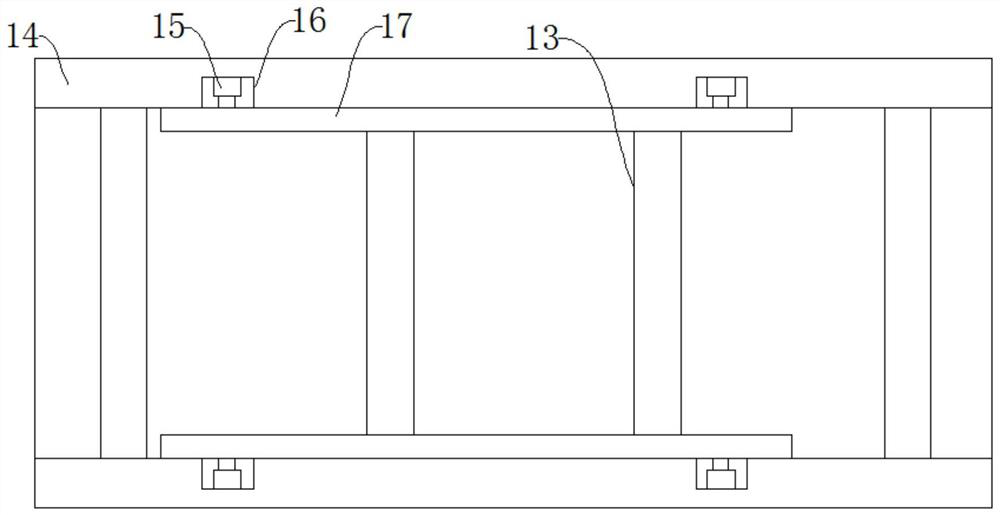

[0035] The present invention will be further described below in conjunction with accompanying drawing:

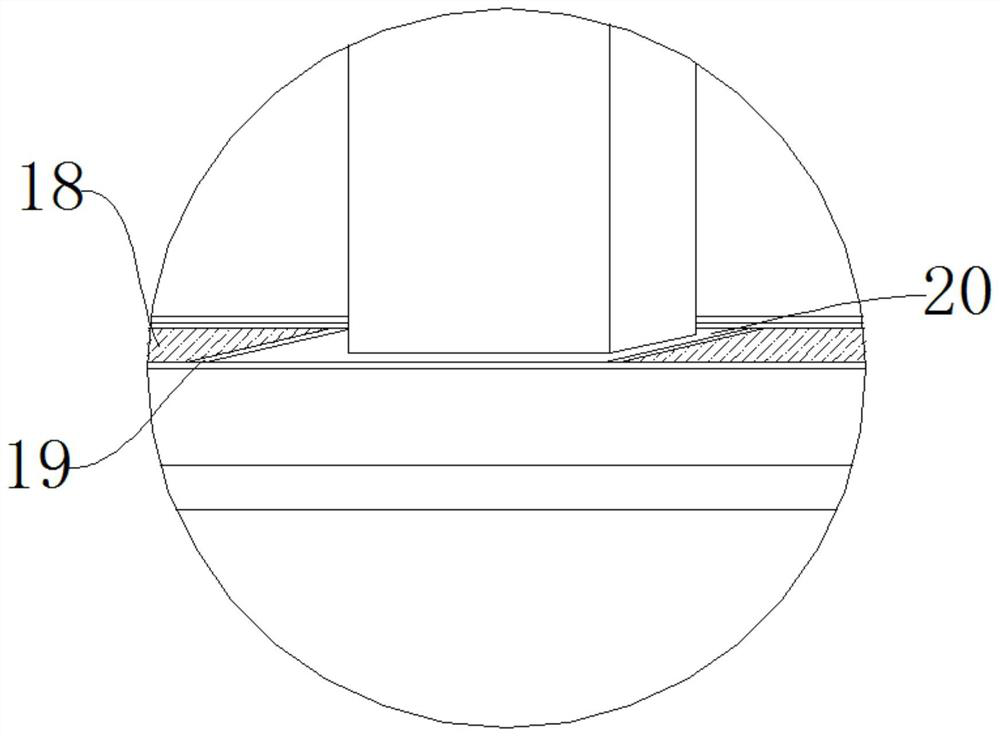

[0036] Such as Figure 1-Figure 6As shown, a texture forming device for artificial quartz stone plates includes a workbench 14, a transmission shaft 13, a mold cavity 12 and a cylinder 16. The transmission shaft 13 is installed in the workbench 14, and the upper end of the transmission shaft 13 is The mold cavity 12 is provided, and a cavity 15 is formed on both side walls of the workbench 14. The cylinder 16 is installed in the cavity 15, and a push plate 17 is fixed at one end of the cylinder 16. Both sides of the upper end of the workbench 14 are fixed with electric slide rails 3, and a slide block 20 is installed in the electric slide rail 3, and there is a gap between the two side walls of the slide block 20 and the two ends of the electric slide rail 3 Folding sealing cover 18, the both sides of described folding sealing cover 18 are provided with connecting plate 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com