A kind of superconducting wire and its preparation method

A superconducting wire and wire technology, applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the problem that the rich elements of superconducting wire cannot be removed, and achieve the effect of improving the practical potential.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

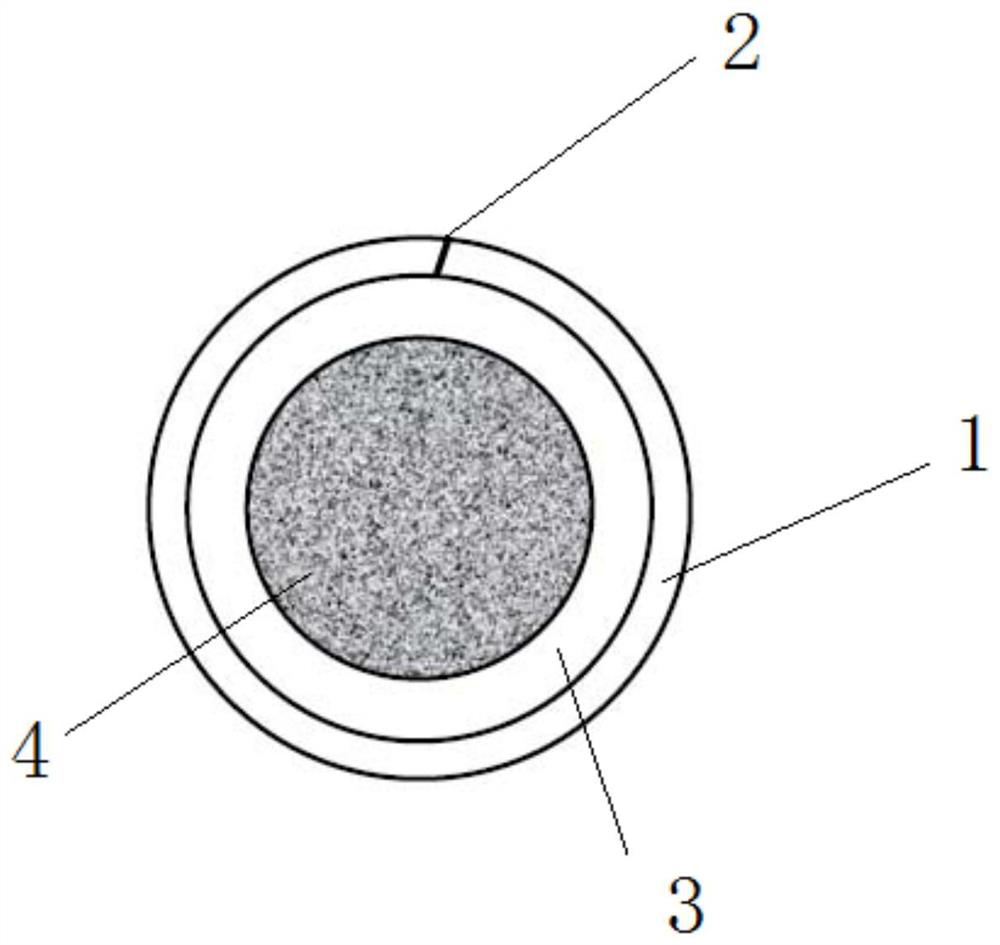

[0044] Such as figure 1 As shown, a superconducting wire includes a single-core wire and a first metal tube 1 covering the single-core wire. The wall of the first metal tube 1 is provided with a The opening 2 of the pipe wall of the first metal pipe 1 .

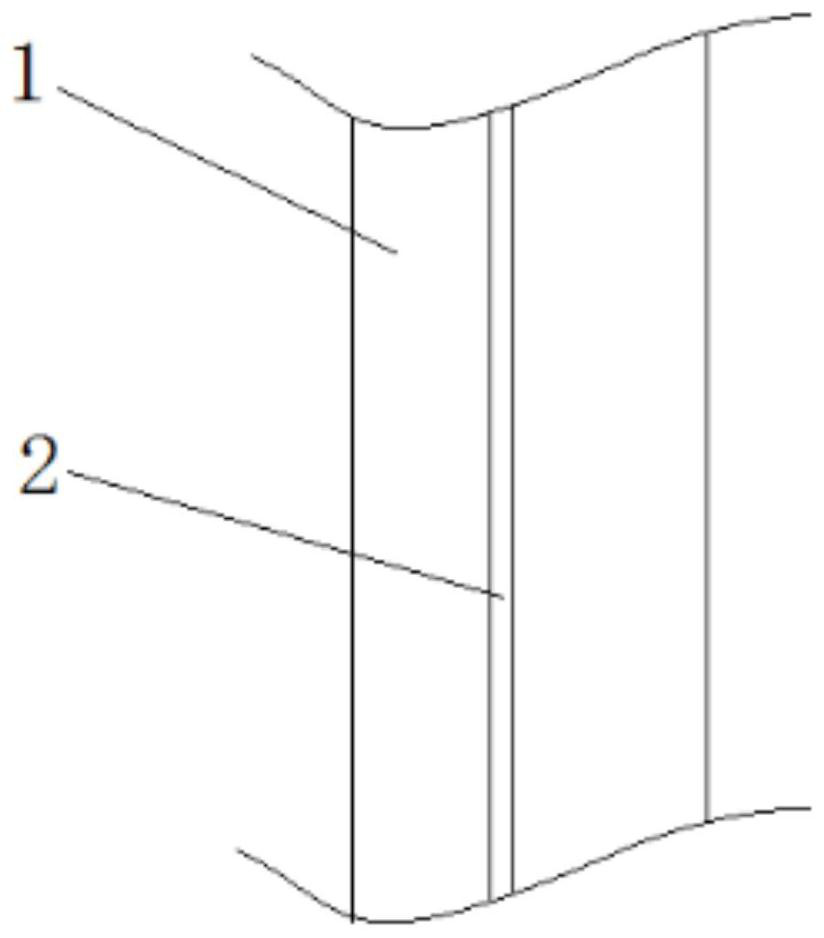

[0045] Such as figure 2 As shown, the opening 2 is a slit with a uniform gap width.

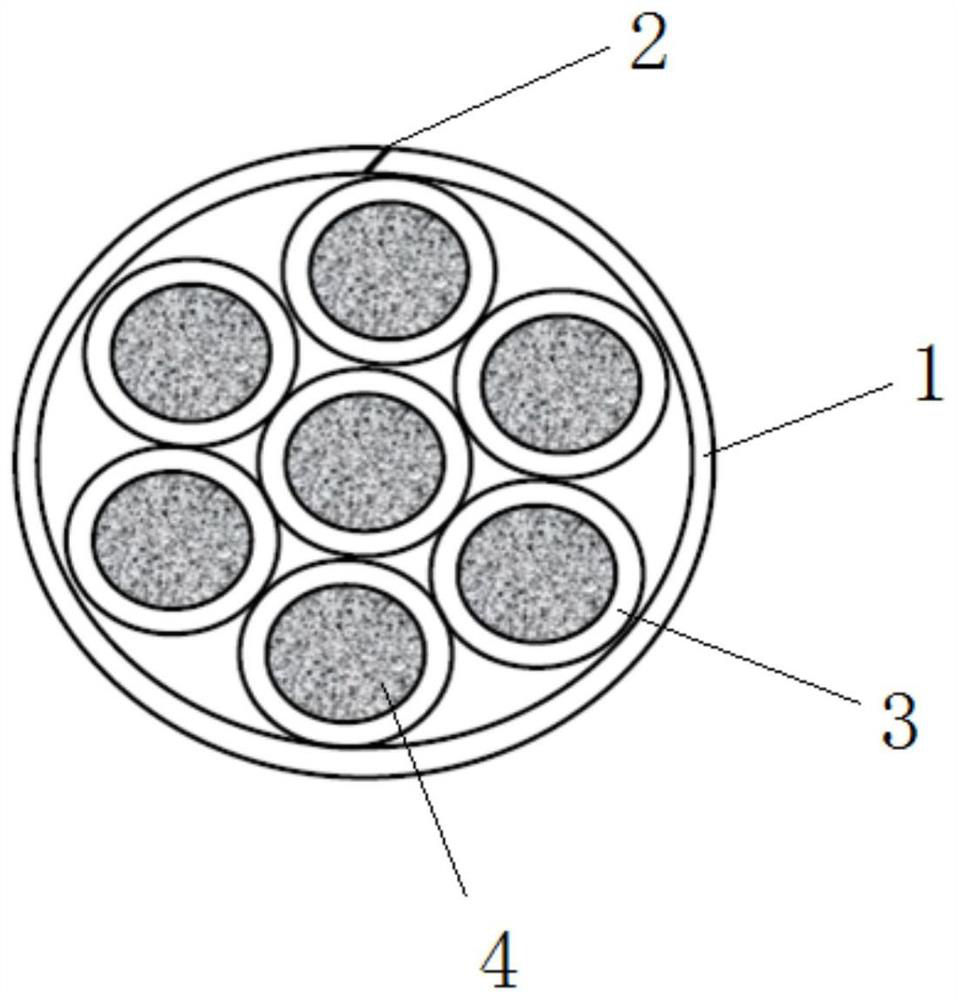

[0046] As another implementation mode of this embodiment, such as image 3 As shown, a superconducting wire includes 7 single-core wires and a first metal tube 1 covering the 7 single-core wires. The wall of the first metal tube 1 is provided with a The opening 2 of the pipe wall of the first metal pipe 1 .

[0047] The single-core wire includes a second metal tube 3 and a precursor powder 4 placed in the second metal tube 3 , and the mechanical strength of the first metal tube 1 is greater than that of the second metal tube 3 .

[0048] When the superconducting wire with this structure is heat-treated, the rich elements in the superco...

Embodiment 2

[0051] This embodiment provides a 7-core Ba 0.6 K 0.4 Fe 2 As 2 Superconducting wire rod and preparation method thereof, the specific steps are as follows:

[0052] Preparation of precursor powder: under argon atmosphere, metal barium chips (mass purity is 99.50%), potassium block (mass purity is 99.95%), iron powder (mass purity is 99.99%) and arsenic particles (mass purity is 99.95%) %), after accurately weighing according to the molar ratio Ba:K:Fe:As=0.6:0.5:2:2, put into a ball mill jar and ball mill for 10 hours. Put the ball-milled powder into the Nb tube, seal both ends with copper plugs, and then heat-treat at 900°C for 50 hours to obtain the precursor powder for superconducting wire;

[0053] Single-core drawing: fill the prepared precursor powder into a silver-tin alloy tube with an inner diameter of 5cm, an outer diameter of 8cm, and a length of 10cm; then seal both ends with Nb plugs to obtain a silver-tin alloy tube composite; The tube-packing composites wer...

Embodiment 3

[0059] This embodiment provides a 1 core Ba 0.6 K 0.4 Fe 2 As 2 Superconducting wire rod and preparation method thereof, the specific steps are as follows:

[0060] Preparation of precursor powder: under argon atmosphere, metal barium chips (mass purity is 99.50%), potassium block (mass purity is 99.95%), iron powder (mass purity is 99.99%) and arsenic particles (mass purity is 99.95%) %), after accurately weighing according to the molar ratio Ba:K:Fe:As=0.6:0.5:2:2, put into a ball mill jar and ball mill for 10 hours. Put the ball-milled powder into the Nb tube, seal both ends with copper plugs, and then conduct heat treatment. The temperature of the heat treatment is 1300 ° C, and the temperature is kept for 0.1 hour to obtain the precursor powder for preparing superconducting wires;

[0061] Single-core drawing: fill the prepared precursor powder into a silver-tin alloy tube with an inner diameter of 5cm, an outer diameter of 8cm, and a length of 10cm; then seal both en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com