Cold end of heavy current lead out wire made from high-temperature superconductor, and low resistance connector of superconducting transmission line

A high-temperature superconducting and superconducting wire technology, which is applied in the direction of superconducting magnets/coils, circuits, electrical components, etc., can solve problems such as difficult, complicated processes, and joints are not considered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

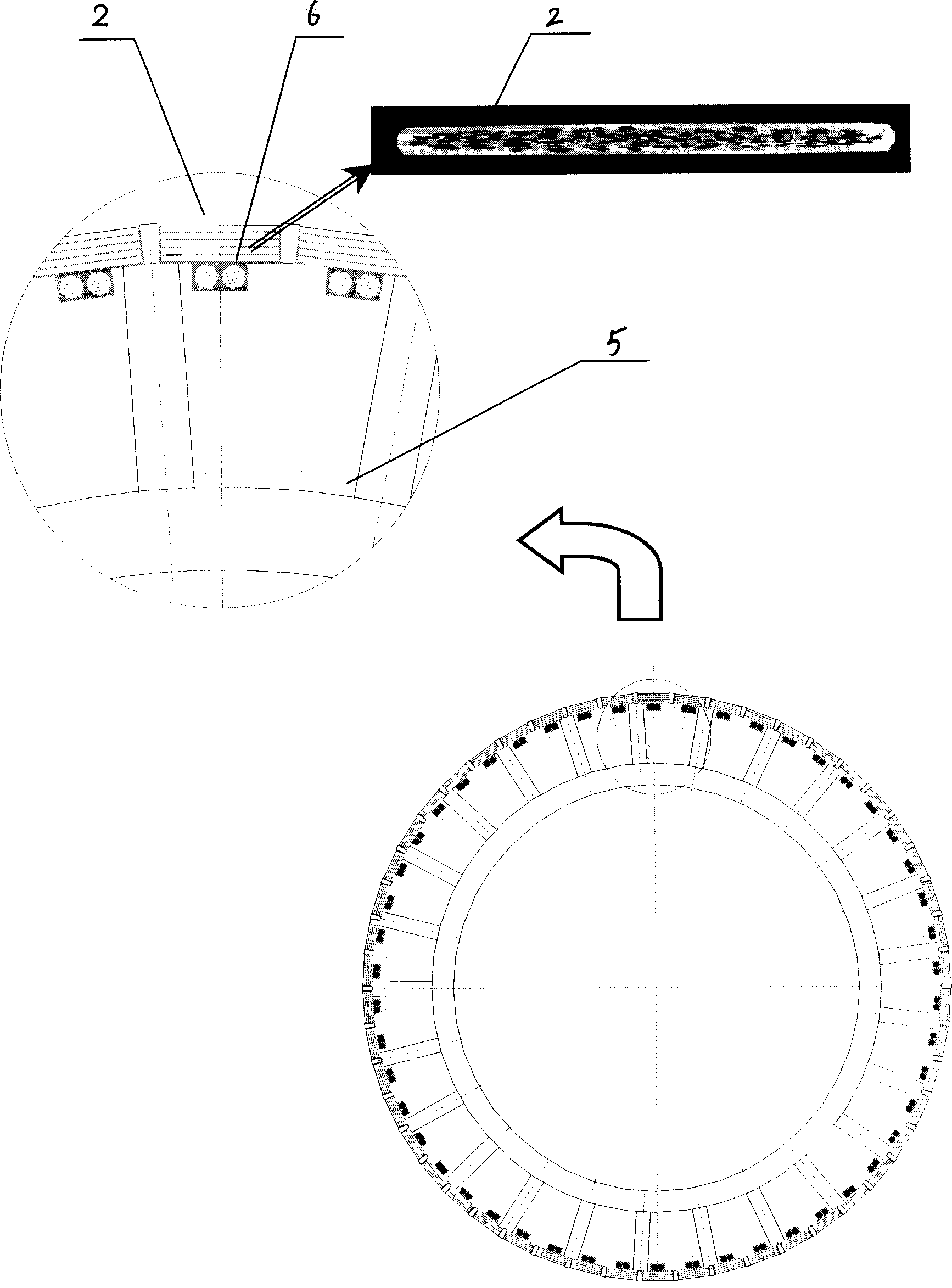

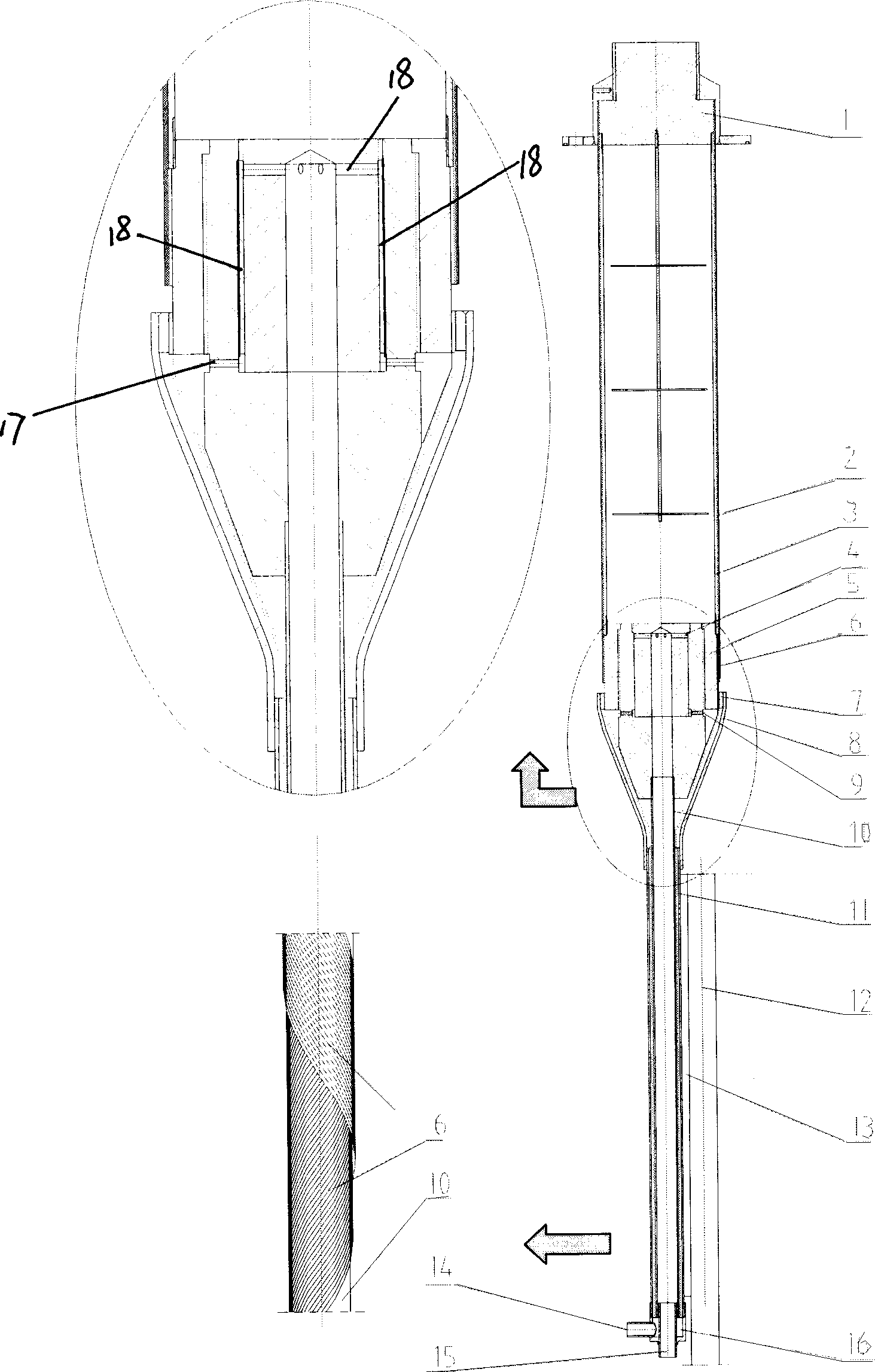

[0019] Labels in the figure: 1. Copper parts at the warm end of the high-temperature superconducting section, 2. High-temperature superconducting stacks, 3. Stainless steel support cylinders with low thermal conductivity, 4. Core plugs with small return holes, 5. High-conductivity copper pipes at the cold ends, 6 .NbTi / Cu superconducting wire (100 pieces), 7. Seal brazing copper ring, 8. Reducer tube, 9. High conductivity copper joint with diversion hole, 10. Inner copper tube, 11. Outer copper tube, 12 .CICC superconducting transmission line end, 13. High conductivity copper spacer, 14. Supercritical helium inflow inlet, 15. Supercritical helium outflow outlet pipe, 16. Air inlet chamber, 17. Diversion hole, 18. Cooling airflow channel .

[0020]The cold end of the high-temperature superconducting high-current lead wire and the low-resistance joint of the superconducting transmission line have a low-thermal-conductivity stainless steel support cylinder 3, and 50 high-temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com