Apparatus for manufacturing membrane electrode assembly, and method for manufacturing membrane electrode assembly

一种膜电极组件、制造装置的技术,应用在膜电极组件制造装置和膜电极组件的制造领域,能够解决热压接的时间短、固体高分子电解质膜与催化剂层粘接弱等问题,达到提高粘接强度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

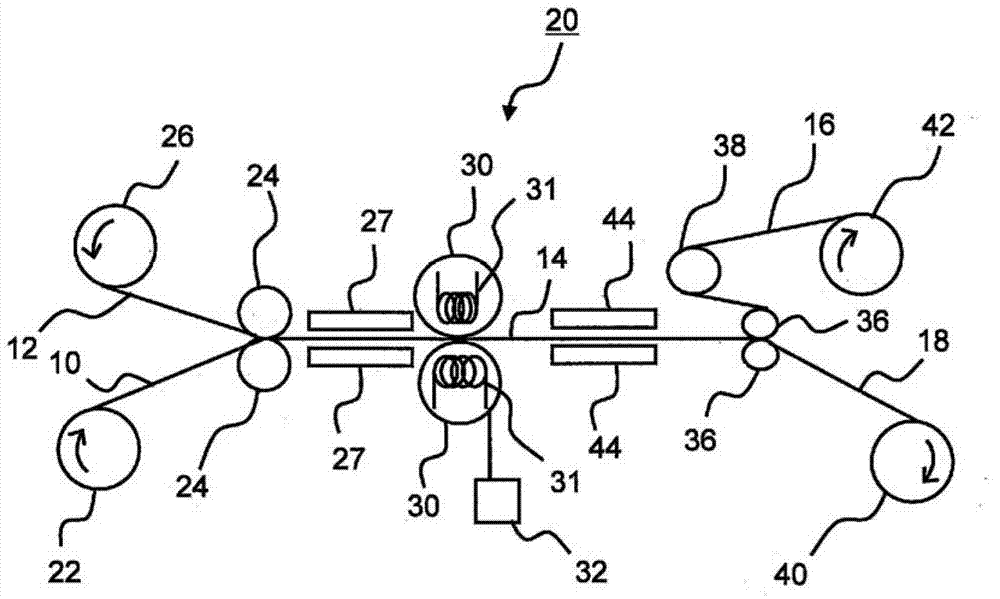

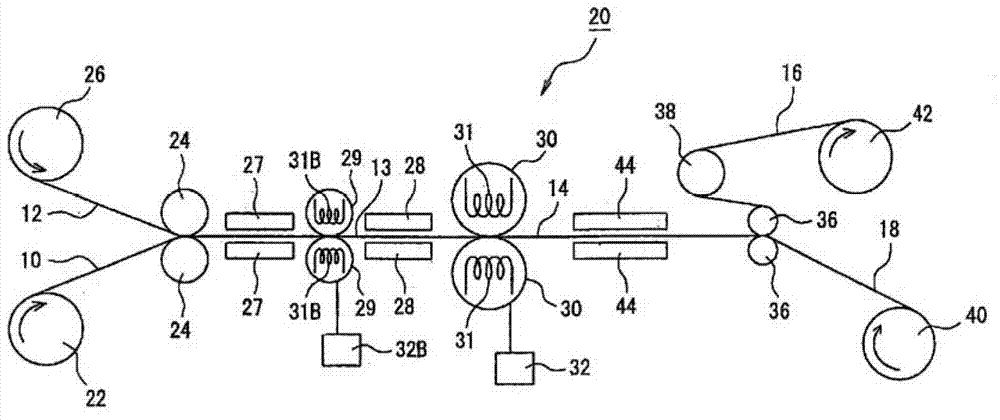

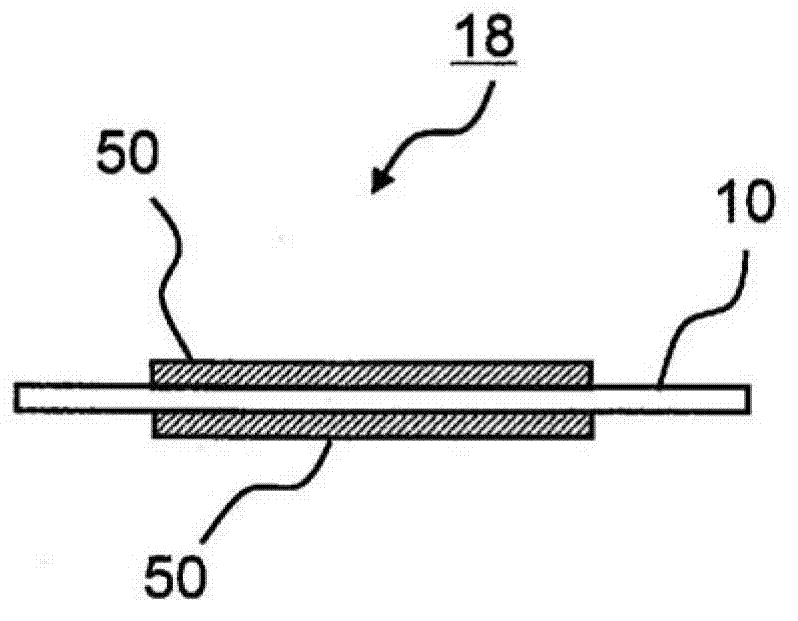

[0041] (Membrane electrode assembly manufacturing equipment)

[0042] Next, an embodiment of the present invention will be explained. In addition, the embodiments of the present invention are not limited to the embodiments described below, and modifications such as design changes can be made based on the knowledge of those skilled in the art. Embodiments with such modifications are also included in the description of the embodiments of the present invention. In the range.

[0043] figure 1 It is a schematic diagram for explaining the membrane electrode assembly manufacturing apparatus 20 of the first embodiment of the present invention. The membrane electrode assembly manufacturing device 20 includes: an unwinding roller 22 for releasing the solid polymer electrolyte membrane 10; a pair of tension removing rollers 24 for removing the tension of the released solid polymer electrolyte membrane 10; and an unwinding roller 26 for Release the catalyst layer bearing substrate 12 with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com