Conductive composition

A technology of composition and mixture, applied in the field of conductive composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

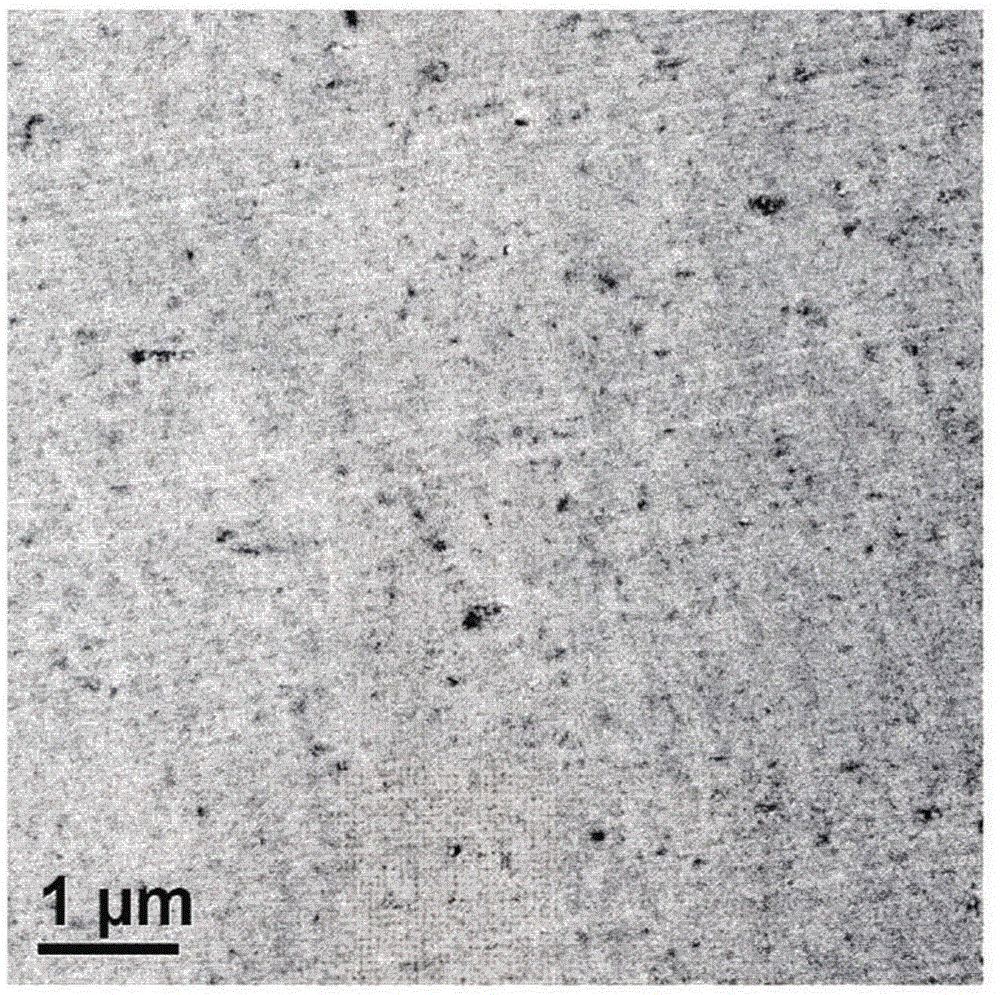

Image

Examples

Embodiment Construction

[0072] Material

[0073] ETHOCEL STD 10 (EC STD 10): ethylcellulose obtained from Dow Chemical, DS: 2.5, M w : 83,000g / mol, PD: 3.30

[0074] ETHOCEL STD 45 (EC STD 45): ethylcellulose obtained from Dow Chemical, DS: 2.5, M w : 158,000g / mol, PD: 3.04

[0075] ETHOCEL STD 100 (EC STD 100): Ethylcellulose obtained from Dow Chemical, DS: 2.5, M w : 214,000g / mol, PD: 3.42

[0076] DC 249: Solid flake hydroxy-functional organopolysiloxane resin with Si-bound methyl and phenyl groups, available from Dow Corning, Si-bound OH group content: 5 wt.%, Ph / Me molar ratio : 1.3 / 1, M w : 2,763g / mol, if passed 29 Structural parameters determined by Si-NMR: a: 0, b: 0.67, c: 0.33, d: 0

[0077]DC 217: Solid flake hydroxy-functional organopolysiloxane resin with Si-bound methyl and phenyl groups, available from Dow Corning, Si-bound OH group content: 6 wt.%, Ph / Me molar ratio : 6.6 / 1, residual SiO 2 Content: 47wt.%, M w : 2,000g / mol, if passed 29 Structural parameters determined by S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com