Liquid metal-based stretchable flexible functional conductor and preparation method thereof

A technology of liquid metal and flexible carrier, which is applied in the direction of cable/conductor manufacturing, equipment for manufacturing conductive/semiconductive layers, conductive layers on insulating carriers, etc., which can solve the problems of decreased conductivity and increased resistance, and achieve conductive The effect of increasing the efficiency, improving the working life and working stability, and realizing large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation of the stretchable flexible functional conductor based on liquid metal, the specific steps are as follows:

[0029] (1) Measure 10 mL of polydimethylsiloxane (model: Dowkaning 189) in a small beaker at room temperature, then use a syringe to measure 2 mL of liquid metal (gallium:indium=3:2, g / g) and add In the polydimethylsiloxane, a cross-shaped stirring paddle was used to stir at a speed of 500 rpm for 10 minutes to obtain a conductive composite material;

[0030] (2) Apply 0.2g of conductive composite material on the medical bandage with a brush, the coating area is a rectangle of 3cm*1cm, connect electrodes at both ends, and dry at 60°C for 2 hours to obtain a stretchable flexible function based on liquid metal conductor.

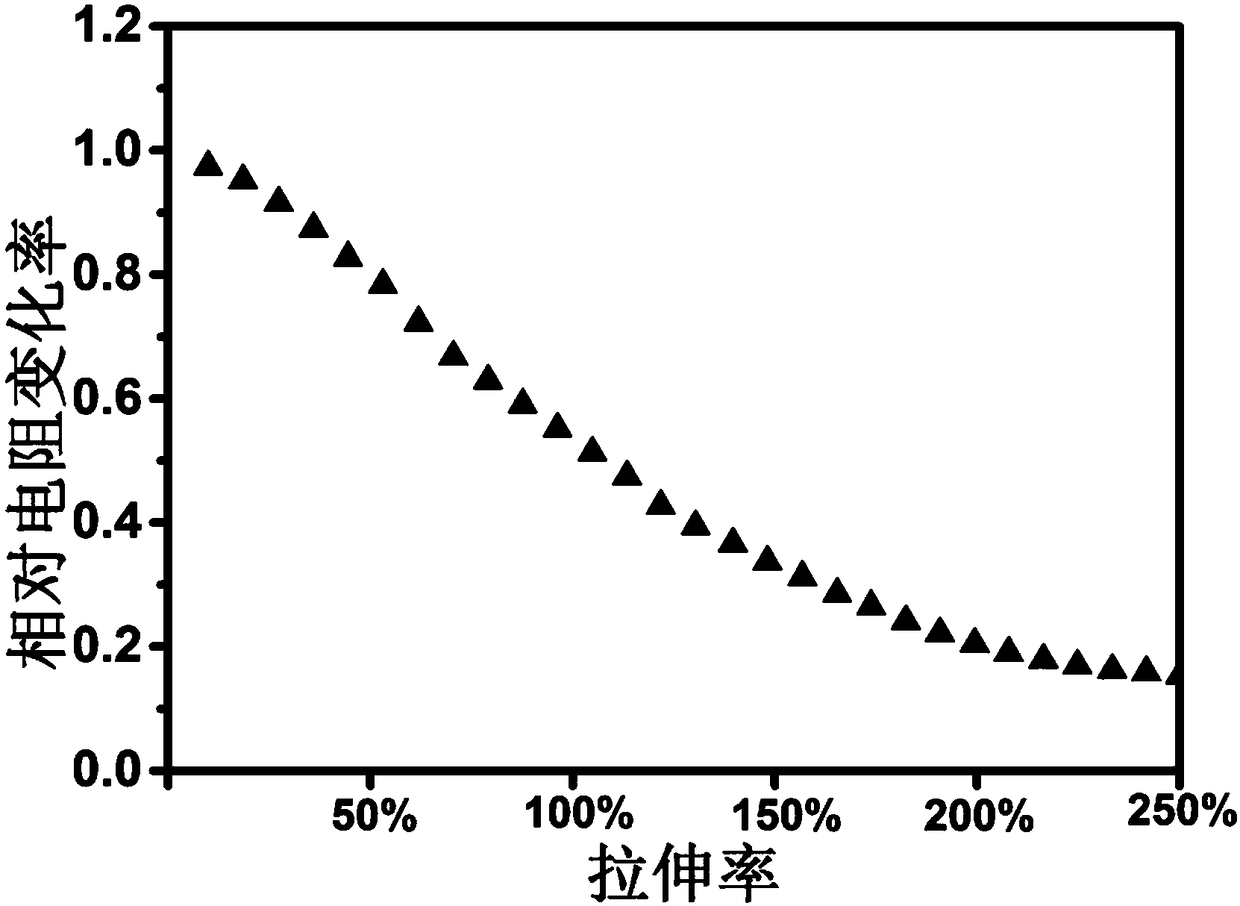

[0031] The resistance of the prepared stretchable flexible functional conductor based on liquid metal is about 15.0Ω; when the conductor is stretched, the relative resistance-deformation curve is as follows figure 1 As shown, as...

Embodiment 2

[0033] The preparation of the stretchable flexible functional conductor based on liquid metal, the specific steps are as follows:

[0034] (1) Measure 10 mL of polyvinyl alcohol solution with a mass fraction of 5% in a small beaker at room temperature, and then use a syringe to measure 5 mL of liquid metal (gallium: indium: tin=3:1:1, g / g / g) adding polyvinyl alcohol solution, using a cross-shaped stirring paddle to stir at a speed of 800rpm for 5min, to obtain a conductive composite material;

[0035] (2) Coat 0.5g of conductive composite material on the cotton fiber non-woven fabric with a brush, the coating area is a rectangle of 3cm*1cm, connect electrodes at both ends, and dry at 60°C for 2h to obtain a liquid metal-based pullable Stretch flexible functional conductor.

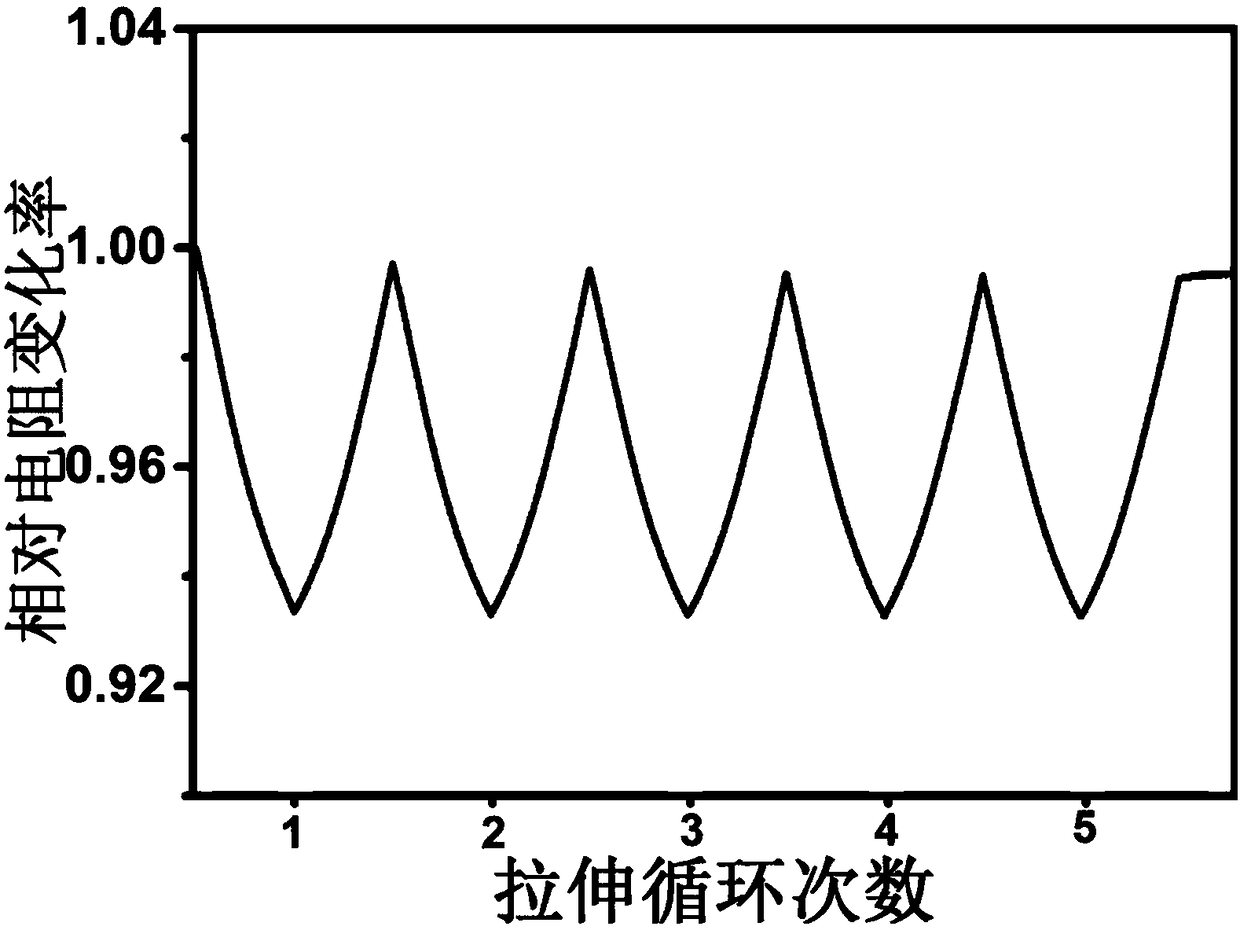

[0036] The resistance of the prepared stretchable flexible functional conductor based on liquid metal is about 10.0Ω; since the hydrophilic polyvinyl alcohol is well combined with the cotton fiber non-wo...

Embodiment 3

[0038] The preparation of the stretchable flexible functional conductor based on liquid metal, the specific steps are as follows:

[0039] (1) Dissolve 1 g of polyurethane (PU) in 9 mL of polydimethylformamide (DMF) at room temperature, stir well to obtain a polyurethane solution; then measure 2 mL of liquid metal (gallium: indium: tin=3 : 2: 1, g / g) into the polyurethane solution, using an ultrasonic cleaner with a power of 400kW, ultrasonically ultrasonicated the mixture for 3 hours at the maximum power to obtain a uniformly dispersed composite system.

[0040] (2) Apply 0.30 g of the composite system on the elastic cloth with a brush, the coating area is a rectangle of 3 cm*1 cm, connect electrodes at both ends, and dry at 60 ° C for 2 hours to obtain a flexible and stretchable sensing material.

[0041] The resistance of the prepared stretchable flexible functional conductor based on liquid metal is about 30.0Ω. Since the polyurethane elastomer molecular chain is relativel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com