Supporting wheel device used for cabling machine

A cable forming machine and roller technology, which is applied in cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of high labor intensity for adjustment, time-consuming and laborious installation, etc., and achieves reduced labor intensity, high bearing strength and high stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

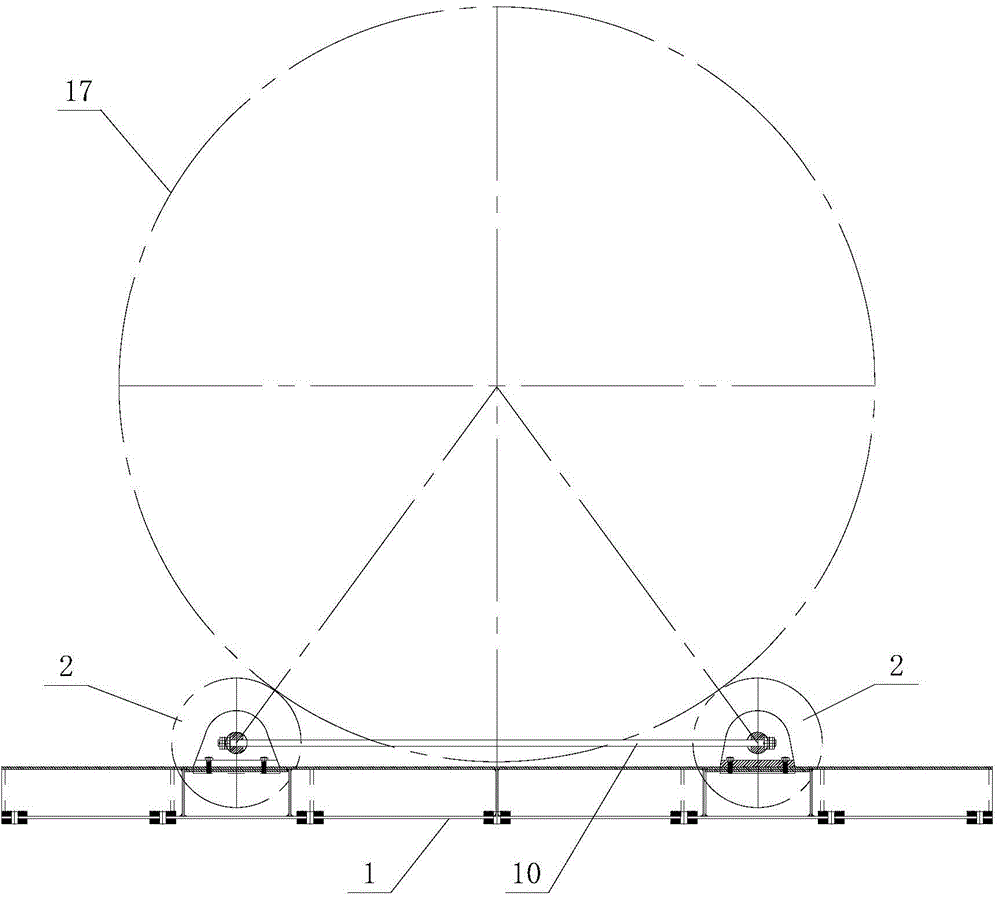

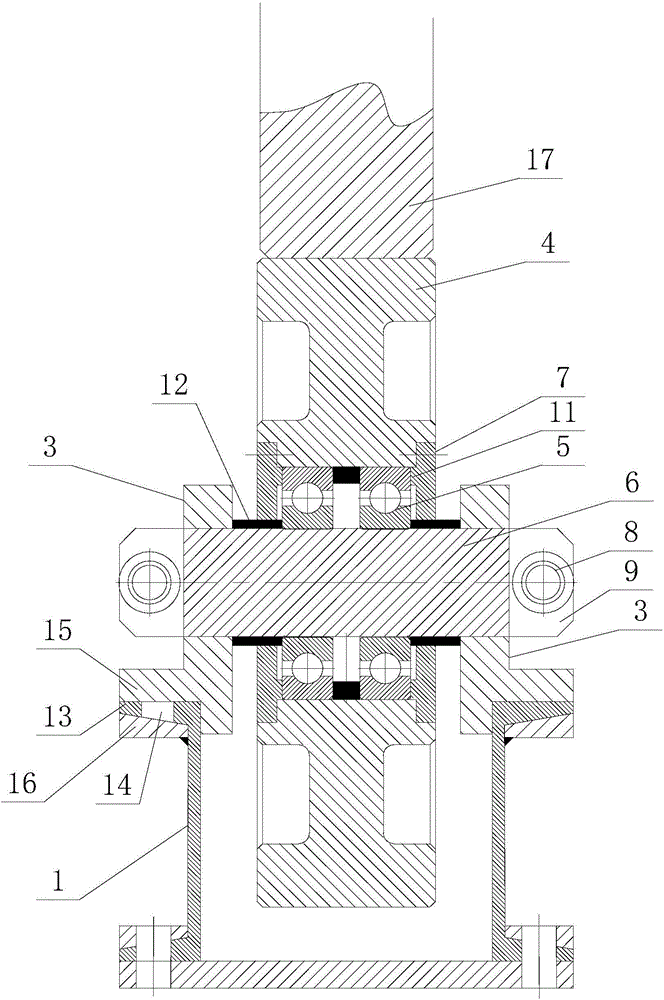

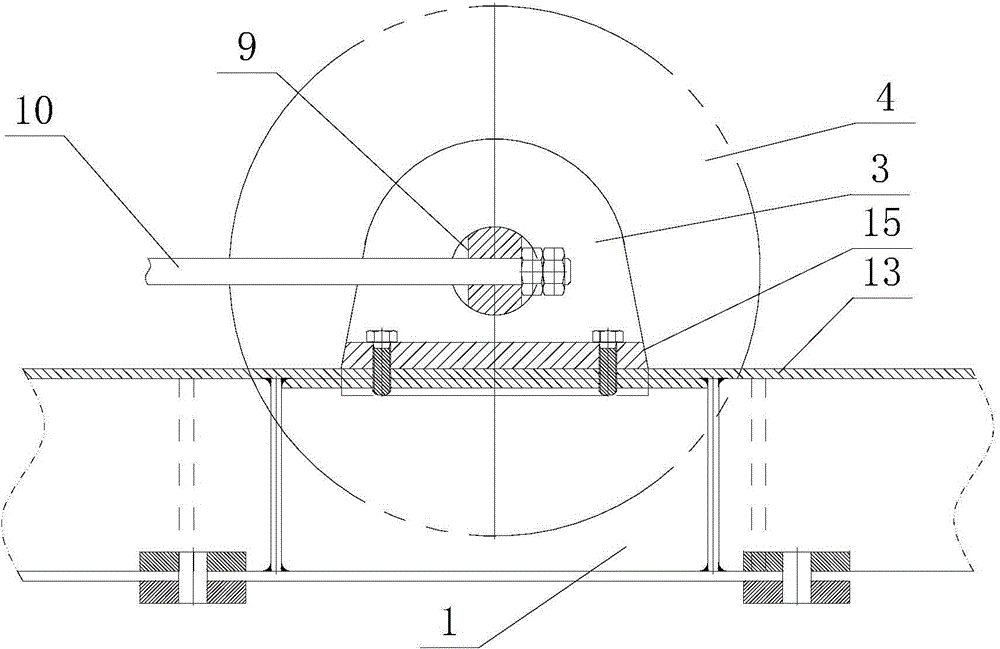

[0012] refer to figure 1 It is an embodiment of a supporting wheel device for a cable forming machine of the present invention, a supporting wheel device for a cable forming machine, comprising an underframe 1, two groups of supporting wheel assemblies 2 arranged on the underframe 1, such as figure 2 , image 3 As shown, each set of supporting wheel assemblies 2 includes two supports 3 fixed on the chassis 1, and a supporting wheel 4 arranged between the two supports 3, and the supporting wheels 4 are sleeved on the On the rotating shaft 6, the rotating shaft 6 on both sides of the bearing 5 is also provided with a transparent cover 7, and the position corresponding to the outer ring of the bearing 5 on the described transparent cover 7 is provided with a ring of bosses 11, and the transparent cover 7 and the supporting wheel 4. It is fixed by bolts. A sealing ring 12 is provided between the transparent cover 7 and the rotating shaft 6. The two ends of the rotating shaft 6 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com