Cabling machine

A technology of cable forming machine and untwisting mechanism, which is applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of difficult to meet the market demand, low cable quality, and low cable forming efficiency of the cable forming machine. Achieve the effects of quality improvement, high cabling efficiency, and avoiding self-torsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

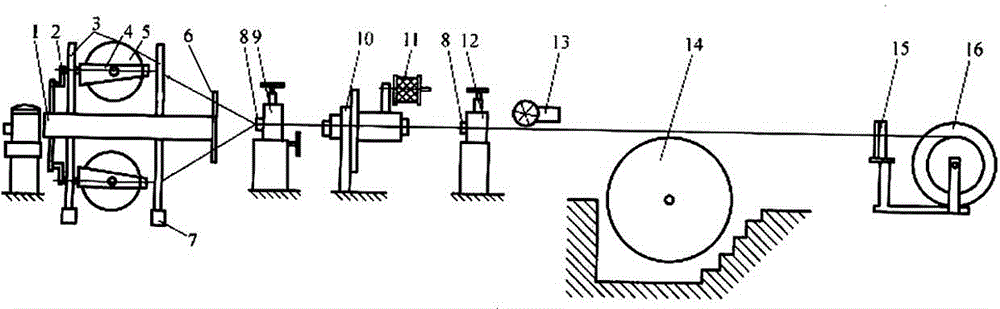

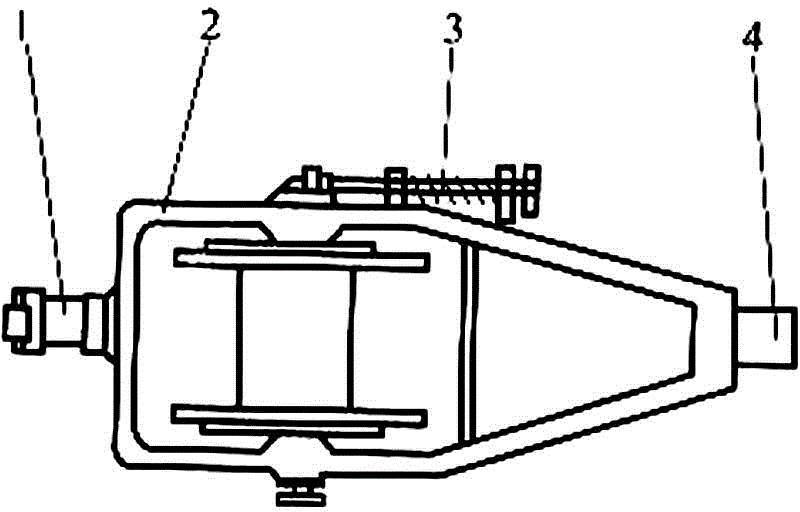

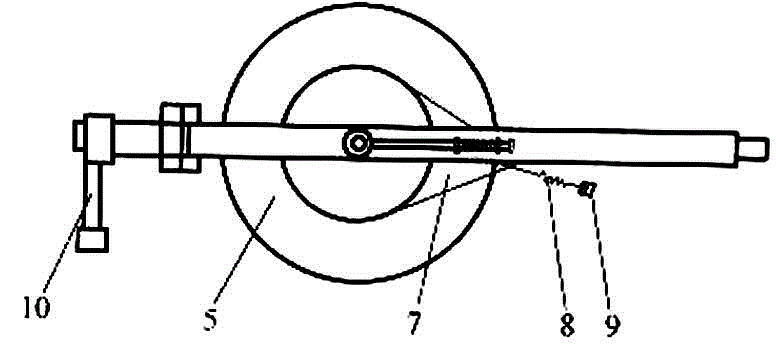

[0016] Such as Figure 1 to Figure 3 As shown, a cable forming machine includes a hollow shaft 1, and the hollow shaft 1 is provided with an untwisting mechanism 2, and the hollow shaft 1 is also provided with two metal rings 3 before and after, one of the metal rings 3 Side is provided with supporting wheel 7.

[0017] A plurality of hurdles 4 are arranged between the metal rings 3, and the hurdles 4 include a front axle and a rear axle, the front axle is a hollow structure, the front axle is equipped with a tooth handle or a gear, and the front axle The diameter of the axle is greater than the diameter of the rear axle.

[0018] A circular pay-off reel 5 is installed on the hurdle 4, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com