Full-automatic hose sheath winding machine

A fully automatic, sheathing machine technology, applied in the field of machinery, can solve the problems such as the inability to match the traveling speed of the hose assembly around the sheath, the inability to adjust, and the obstruction of sheath winding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

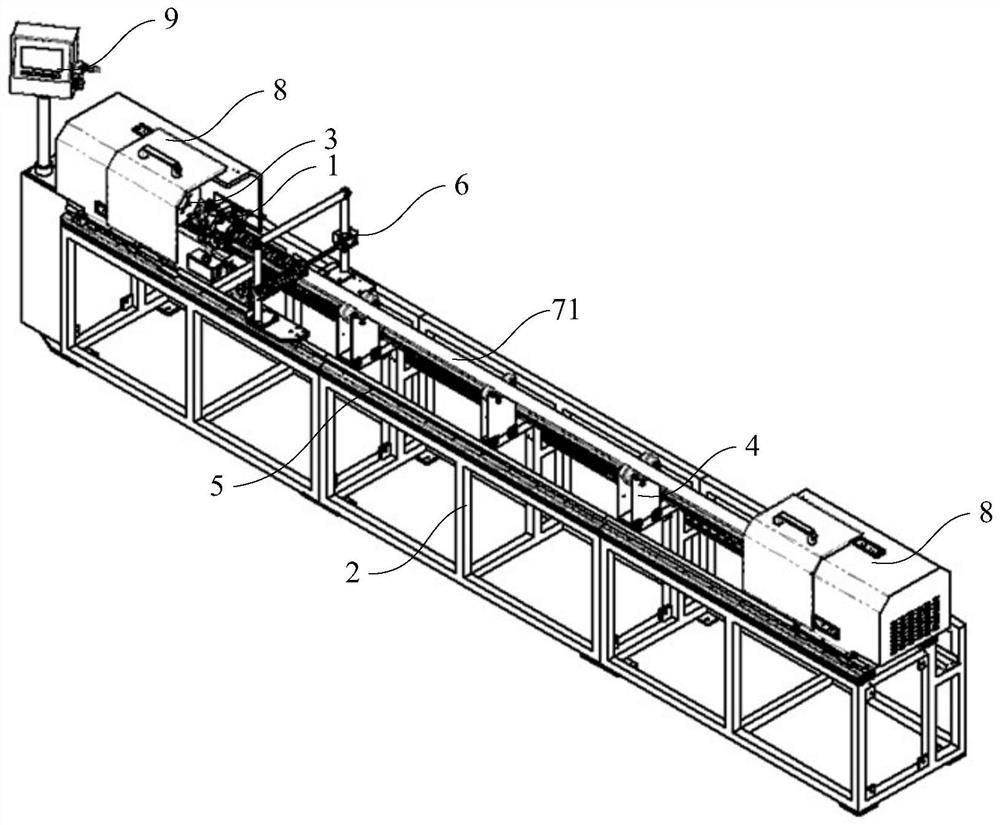

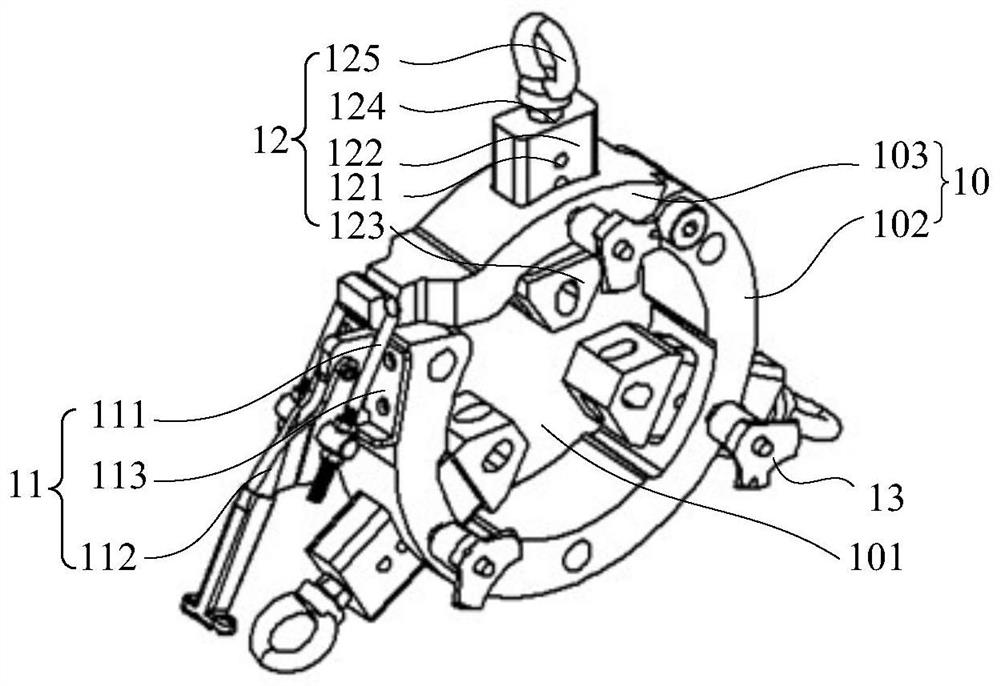

[0055] see figure 1 and figure 2 , a fully automatic hose wrapping machine is provided in this embodiment. The fully automatic hose wrapping machine includes: a frame 2, and the frame 2 is provided with guide rails 5 arranged in parallel at intervals. The guide rails 5 extend along the length direction of the frame 2; the control end machine head 3, the control end machine head 3 is located on the frame 2, is located between the guide rails 5, and is connected to the guide rails 5 , can slide along the guide rails 5; the free end head (not shown), the free end head is located on the frame 2, between the guide rails 5, connected with the guide rails 5, can Sliding along the guide rail 5, and the free end machine head has a distance from the control end machine head 3; the pneumatic tensioning device 91, the pneumatic tensioning device 91 is located at the bottom of the control end machine head 3, and the The control end machine head 3 is connected; the locking device 1, the ...

Embodiment 2

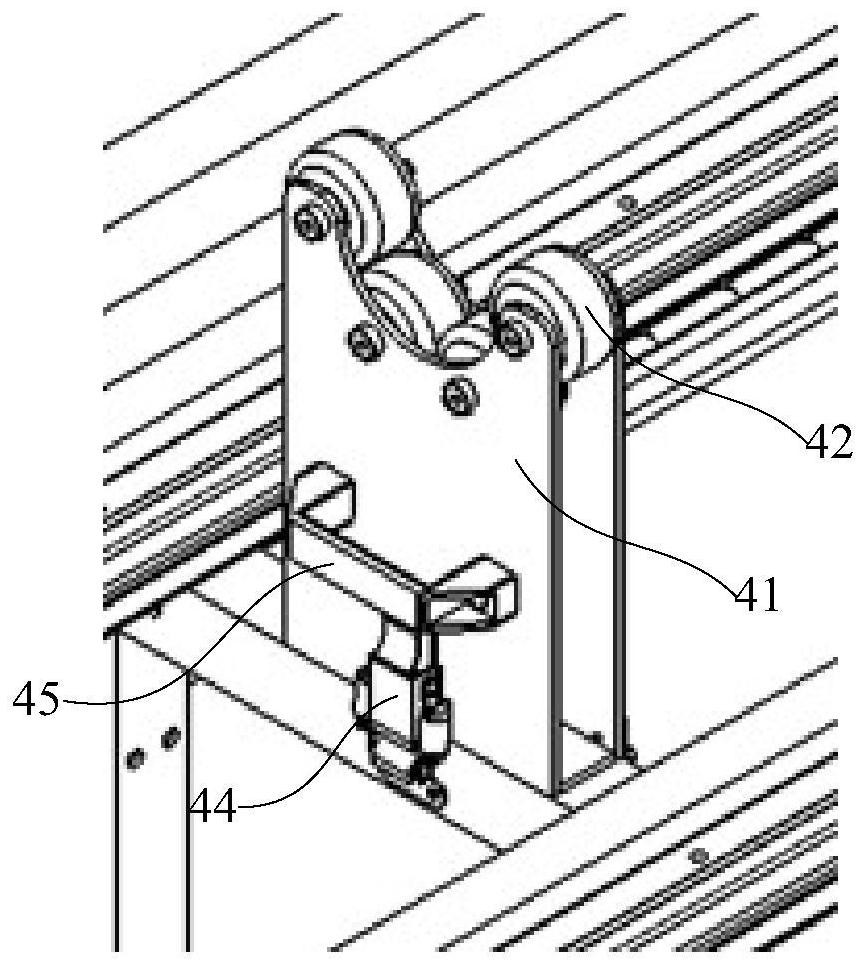

[0072] Please combine figure 1 and figure 2 refer to image 3 and Figure 4 , this embodiment also provides a fully automatic hose wrapping machine, the structure of the fully automatic hose wrapping machine described in this embodiment and the fully automatic hose wrapping machine described in Embodiment 1 Roughly the same, the difference between the two is: compared with the fully automatic hose wrapping machine in the first embodiment, the fully automatic hose wrapping machine described in this embodiment also includes a roller device 4, so The idler device 4 is located between the locking devices 1 for supporting the rubber hose assembly 71; the idler device 4 includes: a bracket 41, the bottom of which is fixed to the On the frame 2; the roller 42, the roller 42 is fixed on the top of the bracket 41; the hinge 43, the hinge 43 is located at the bottom of one side of the bracket 41, to connect the bracket 41 with the The frame 2 is hinged; the lock 44 is located at th...

Embodiment 3

[0078] Please combine Figure 1 to Figure 4 refer to Figure 6 , this embodiment also provides a fully automatic hose wrapping machine. The structure of the casing machine is roughly the same. The difference between the fully automatic hose wrapping machine in this embodiment and the above two embodiments is that in the fully automatic hose wrapping machine described in this embodiment, The guide rail 5 is located on the outside of the control end head 3 and the free end head, and extends along the length direction of the frame 2; the fully automatic hose wrapping machine also includes a second servo motor (not shown) and a second speed reducer (not shown), the second speed reducer is connected with the second servo motor; the fully automatic hose winding sheath machine also includes a sheath stroker 6, Such as Figure 6 As shown, the sheath stroker 6 includes: a stroke slide 61, the stroke slide 61 is arranged on the guide rail 5, connected with the second speed reducer, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com