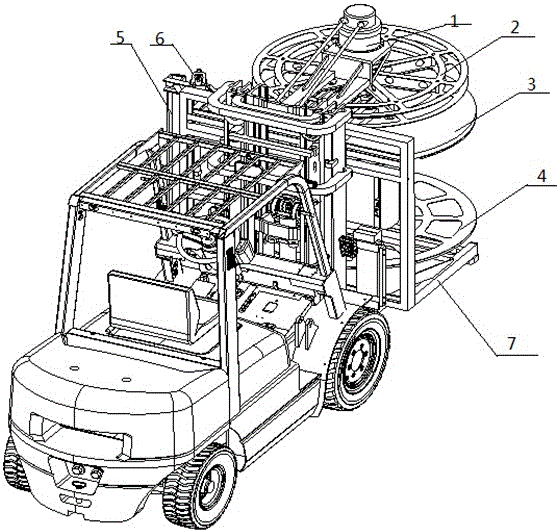

Forklift accessory optical cable automatic winding-unwinding mechanism

An automatic retractable and forklift technology, which is applied in the field of optical cable construction, can solve the problems of large amount of engineering, labor-intensive, and labor-intensive, and achieve the effects of novel structure, convenient operation, and labor-saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

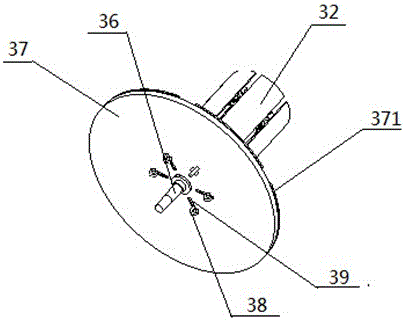

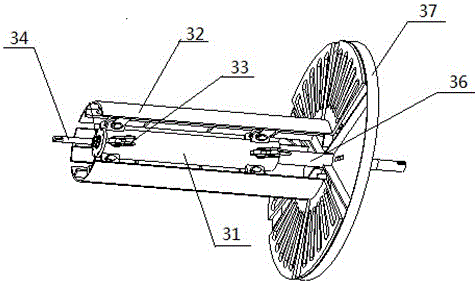

[0021] Such as figure 1 , 2 , 3, 4, and 5, the present invention discloses a forklift attachment optical cable automatic retractable mechanism, which consists of a hydraulic motor 1, a cable reel 2, an expansion-contractable retractable device 3, a lower tray 4, and a cable The device 5, the cable unwinding drive device 6, and the optical cable rack 7 are composed of the optical cable rack 7, which is installed on the fork of the forklift, and the forklift is used for carrying and moving the automatic retractable mechanism of the optical cable and provides a guide for the guide cable. Power, the expansion and contraction type retractable device 3 includes: cable tube core 31, arc cable tube piece 32, rocker arm 33, screw nut pair 34, bearing seat 35, mandrel 36, outer baffle plate 37, roller 38 , the roller groove 39, the two ends of the cable drum core 31 are circumferentially equipped with lugs 311, and the arc cable drum sheets 32 are six circumferentially distributed outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com