Method and apparatus for filling type communication cable compound filling

A technology for communication cables and filling methods, applied in the direction of insulating cables, insulating conductors/cables, cables, etc., can solve the problems of unsatisfactory filling of composites, waste of raw materials, increase of manufacturing costs, etc., and achieve qualified water seepage performance, production and operation. Convenience, the effect of improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

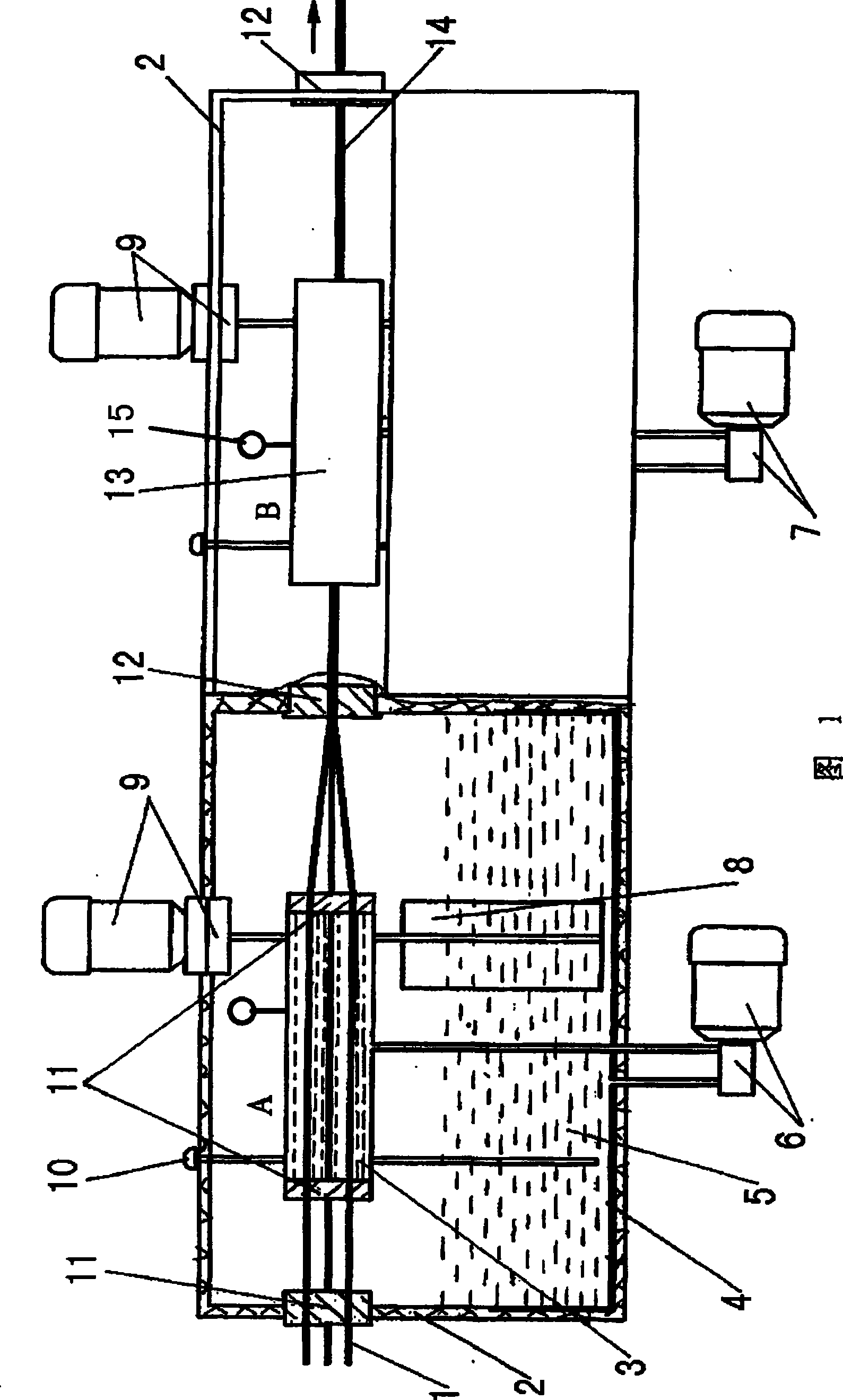

[0010] The present invention will be further described below in conjunction with FIG. 1 and the embodiments.

[0011] Fig. 1 is a schematic diagram of the communication cable compound filling equipment. In the figure, it includes two independent first filling systems A and second filling systems B, with a common semi-closed box 2, composed of semi-closed box 2 The partition in the middle is divided into two filling systems with the same structure, and the middle of the partition contains heat insulating material to ensure that the compound temperature of the two systems does not affect each other. A single-hole mold 12 is installed on the partition in the middle of the semi-closed box 2, and a single-hole mold 12 is also installed on the right end wall of the semi-closed box 2; in the filling system A, the unit cable 1 passes through the semi-closed box. The porous mold 11 installed on the left end wall of the box body 2 and the two ends of the first filling cavity 3 enters th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com