Skeleton type optical fiber ribbon cabling machine and cabling method using cabling machine

An optical fiber ribbon and cabling machine technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of large accumulated error, fiber optic ribbon breakage, and cabling can not continue, and achieves the effect of ensuring the production process and smooth and smooth groove entry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described in conjunction with the following examples.

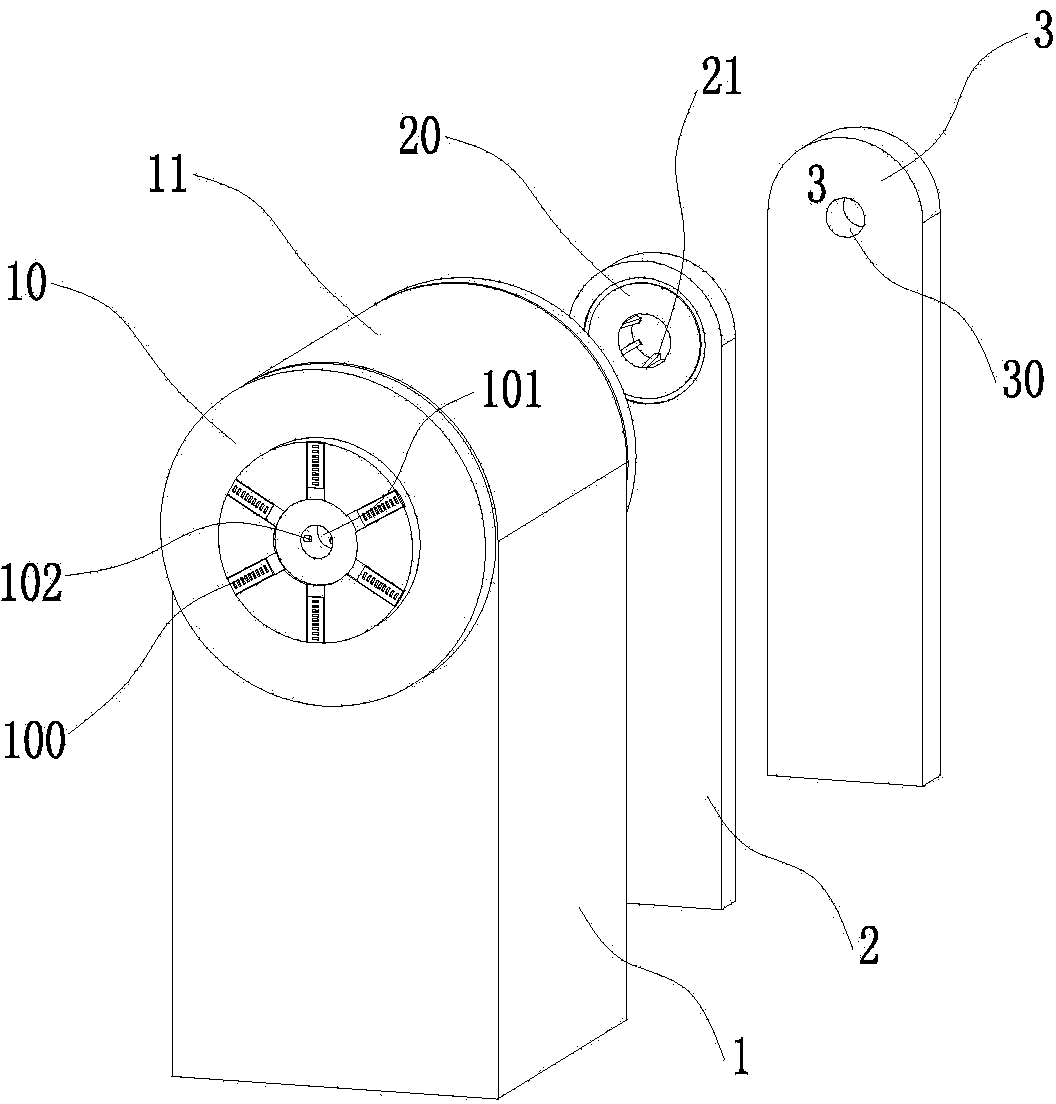

[0026] A skeleton type optical fiber ribbon cable forming machine, such as figure 1 As shown, it includes a console, a wire-feeding device, a trough-entry device and a wire-receiving device, wherein the wire-paying device, the trough-entry device and the wire-receiving device are all uniformly controlled by the console. The slotting equipment includes a twisting device 1 , a slotting die 2 and a sizing die 3 arranged in sequence along the advancing direction of the skeleton.

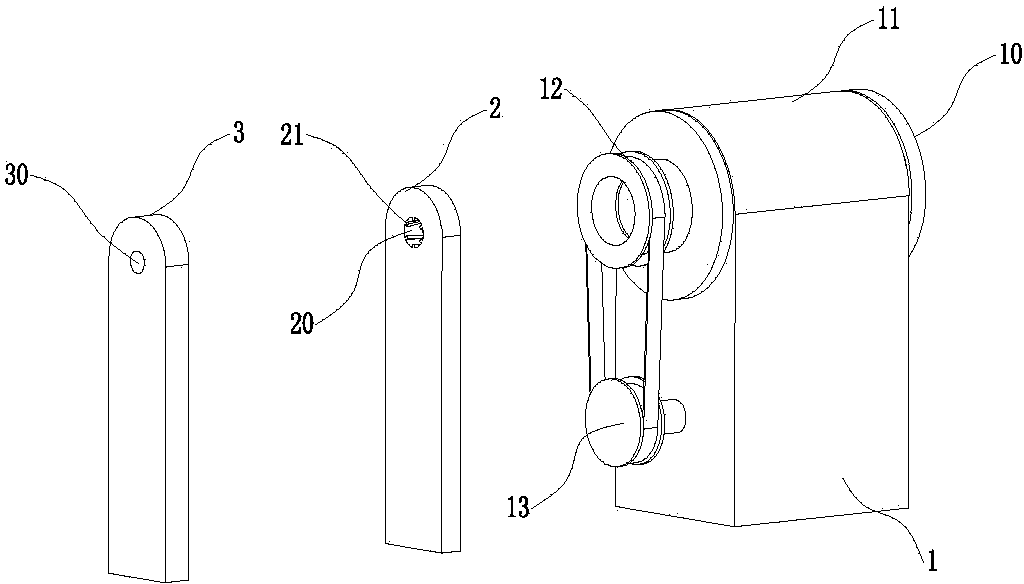

[0027] Such as figure 2 As shown, the twisting device 1 includes a twisting bearing seat 11 , a groove-in adjustment disc 10 , a sensing gear 12 and a sensing device 13 . Wherein, the sensing device 13 is provided with an angle sensor, and the slot-in adjustment disc 10 is connected with the sensing gear 12 through a hollow shaft, and the sensing gear 12 drives the sensing device 13 to rotate, and the sensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com