Slotting device for abrasive freezing and solidifying polishing pad

A technology of consolidating abrasives and polishing pads, which is applied in the direction of grinding devices, grinding/polishing equipment, abrasives, etc., can solve the problems of uneven distribution of polishing stress, unsatisfactory polishing effect, and low removal rate of polishing pads. Optimal polishing stress distribution, high cost performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

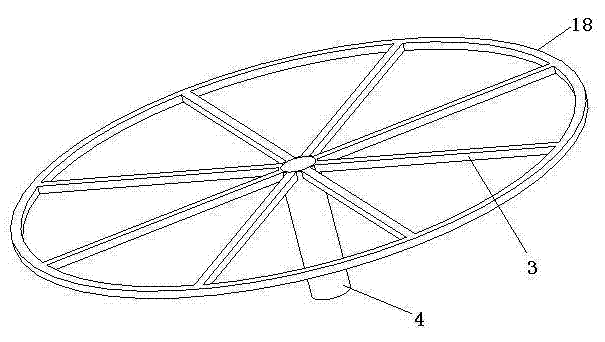

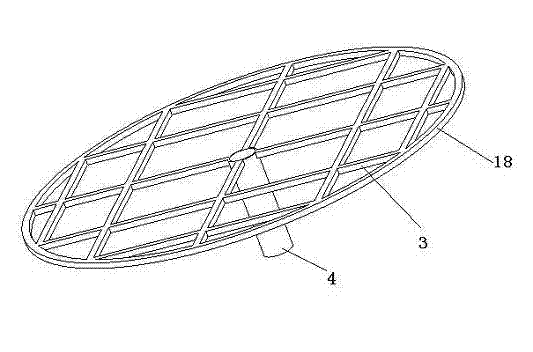

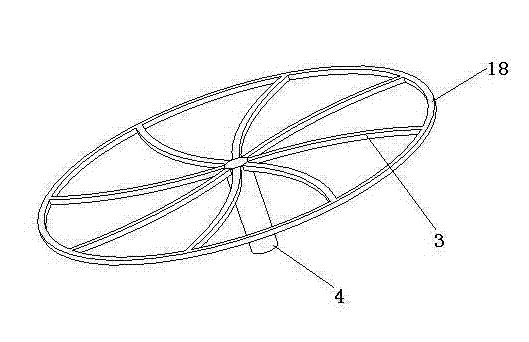

[0044] Such as Figure 1-6 shown.

[0045] A grooving device for a frozen solidified abrasive polishing pad, which mainly consists of the following components:

[0046] A slotting mold 1, the side of the slotting mold 1 opposite to the frozen solidified abrasive polishing pad 2 is provided with matching raised ribs 3, and the center of the slotting mold 1 is provided with a support column 4 (length Generally between 65mm and 100mm); the structural diagram of the slotting die 1 is as follows Figure 1-3 As shown, it can also be designed into other shapes according to the needs during specific implementation. The material of the slotting mold 1 can be LY12, 6061 alloy aluminum and other materials with good thermal conductivity and high hardness. In order to increase the strength, a circle of reinforcement ring 18 is set on the outer ring ; figure 1 The protruding ribs 3 are radial, figure 2 The raised ribs are grid-shaped, image 3 The raised ribs 3 are in a helical st...

Embodiment 2

[0054] Such as Figure 1-3 , 5-9 shown.

[0055] A grooving device for a frozen solidified abrasive polishing pad, which mainly consists of the following components:

[0056] A slotting mold 1, the side of the slotting mold 1 opposite to the frozen solidified abrasive polishing pad 2 is provided with matching raised ribs 3, and the center of the slotting mold 1 is provided with a support column 4 (length Generally between 65mm and 100mm); the structural diagram of the slotting die 1 is as follows Figure 1-3 As shown, it can also be designed into other shapes according to actual needs. The material of the slotting mold 1 can be LY12, 6061 alloy aluminum and other materials with good thermal conductivity and high hardness. In order to increase the strength, it is best to set a ring on the outer ring to strengthen Circle 18; figure 1 The protruding ribs 3 are radial, figure 2 The raised ribs are grid-shaped, image 3 The raised ribs 3 are in a helical structure;

[00...

Embodiment 3

[0064] Such as Figure 1-3 , 10 shown.

[0065] A grooving device for a frozen solidified abrasive polishing pad, which mainly consists of the following components:

[0066] A slotting mold 1, the side of the slotting mold 1 opposite to the frozen solidified abrasive polishing pad 2 is provided with matching raised ribs 3, and the center of the slotting mold 1 is provided with a support column 4 (length Generally between 65mm and 100mm); the structural diagram of the slotting die 1 is as follows Figure 1-3 As shown, it can also be designed into other shapes according to the needs during specific implementation. The material of the slotting mold 1 can be LY12, 6061 alloy aluminum and other materials with good thermal conductivity and high hardness. In order to increase the strength, a circle of reinforcement ring 18 is set on the outer ring ; figure 1 The protruding ribs 3 are radial, figure 2 The raised ribs are grid-shaped, image 3 The raised ribs 3 are in a helic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com