Live center mechanism of cabling machine cradle

A cable forming machine, top-notch technology, applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of low production efficiency, time-consuming and laborious disk replacement, cumbersome operating procedures, etc., to achieve high production efficiency, compact structure, transmission high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

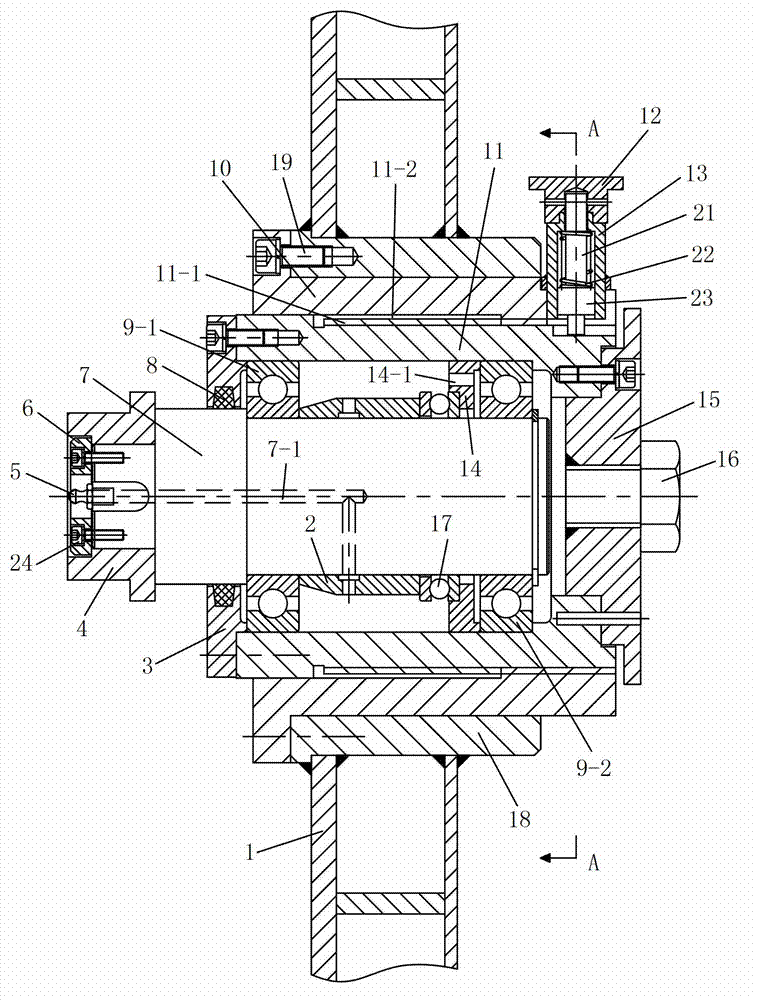

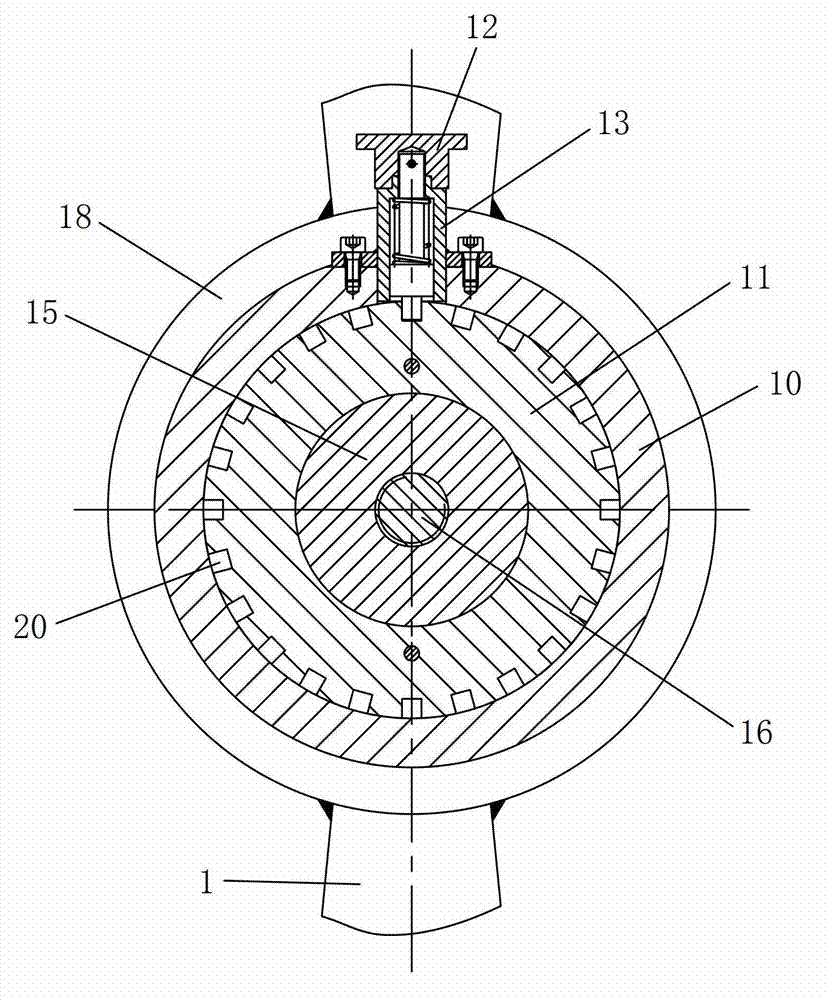

[0033] Such as figure 1 and figure 2 As shown, the present invention comprises a frame 1, an axle 7, a fixed sleeve 10, a moving sleeve 11 and a positioning mechanism for positioning the moving sleeve 11, the shaft 7 is arranged on the frame 1, and the moving sleeve 11 is rotatably mounted on On the shaft 7, the fixed sleeve 10 is arranged outside the moving sleeve 11 and is fixedly connected with the frame 1. The left end of the moving sleeve 11 is fixedly equipped with a bearing cover 3, and the right end of the moving sleeve 11 is fixedly installed with a second press. Cover 15, the left end of the shaft 7 passes through the bearing cover 3 and the end is equipped with a top 4, the right end of the shaft 7 is located inside the moving sleeve 11, and the center of the second gland 15 is provided with a through hole, so An outer hexagonal screw 16 is welded on the through hole; a first thread 10-1 is provided on the inner circle of the fixed sleeve 10, and a first thread 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com