Temporary supporting piece for installation of ropeway of cabling machine

A cableway and temporary technology, applied in the direction of cable cranes, cranes, transportation and packaging, etc., can solve the problems of hoisting machines and ground anchors with large bearing capacity, and achieve the effect of improving safety and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with embodiment the present invention is further described.

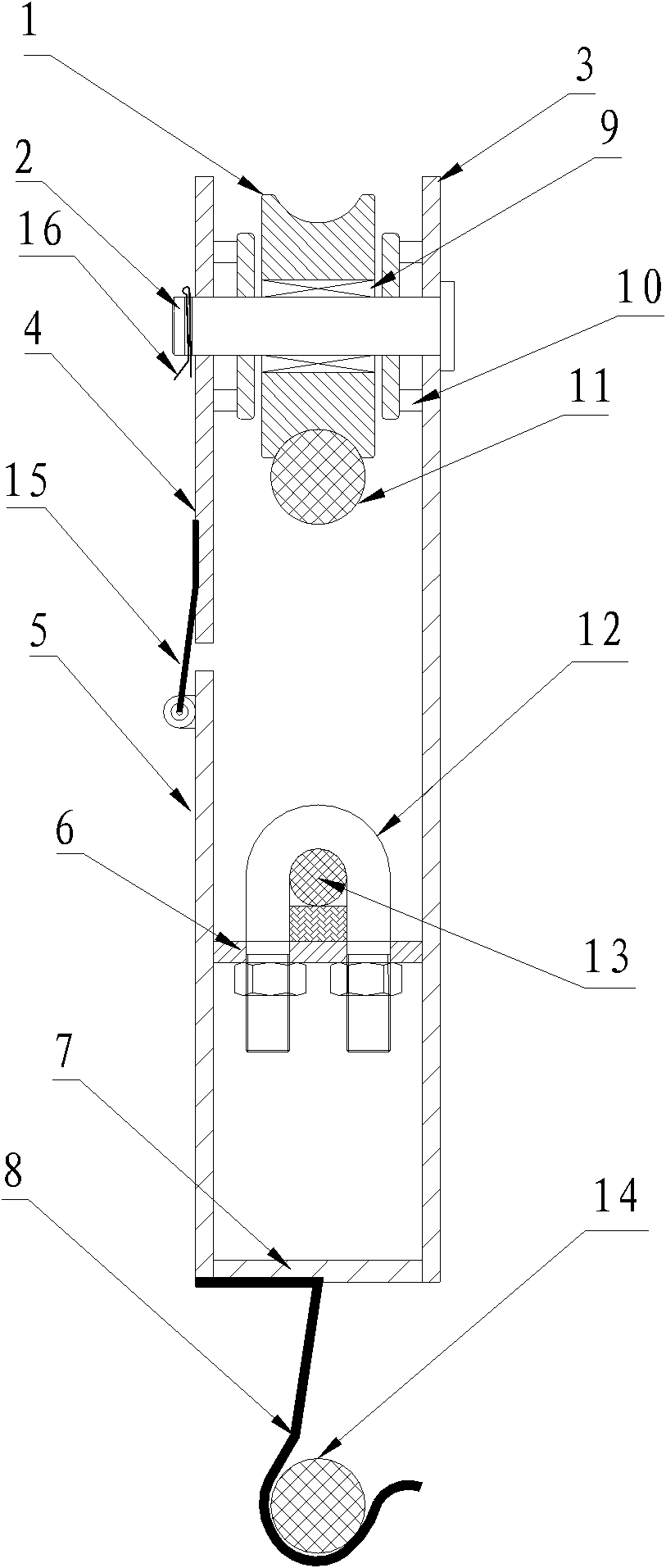

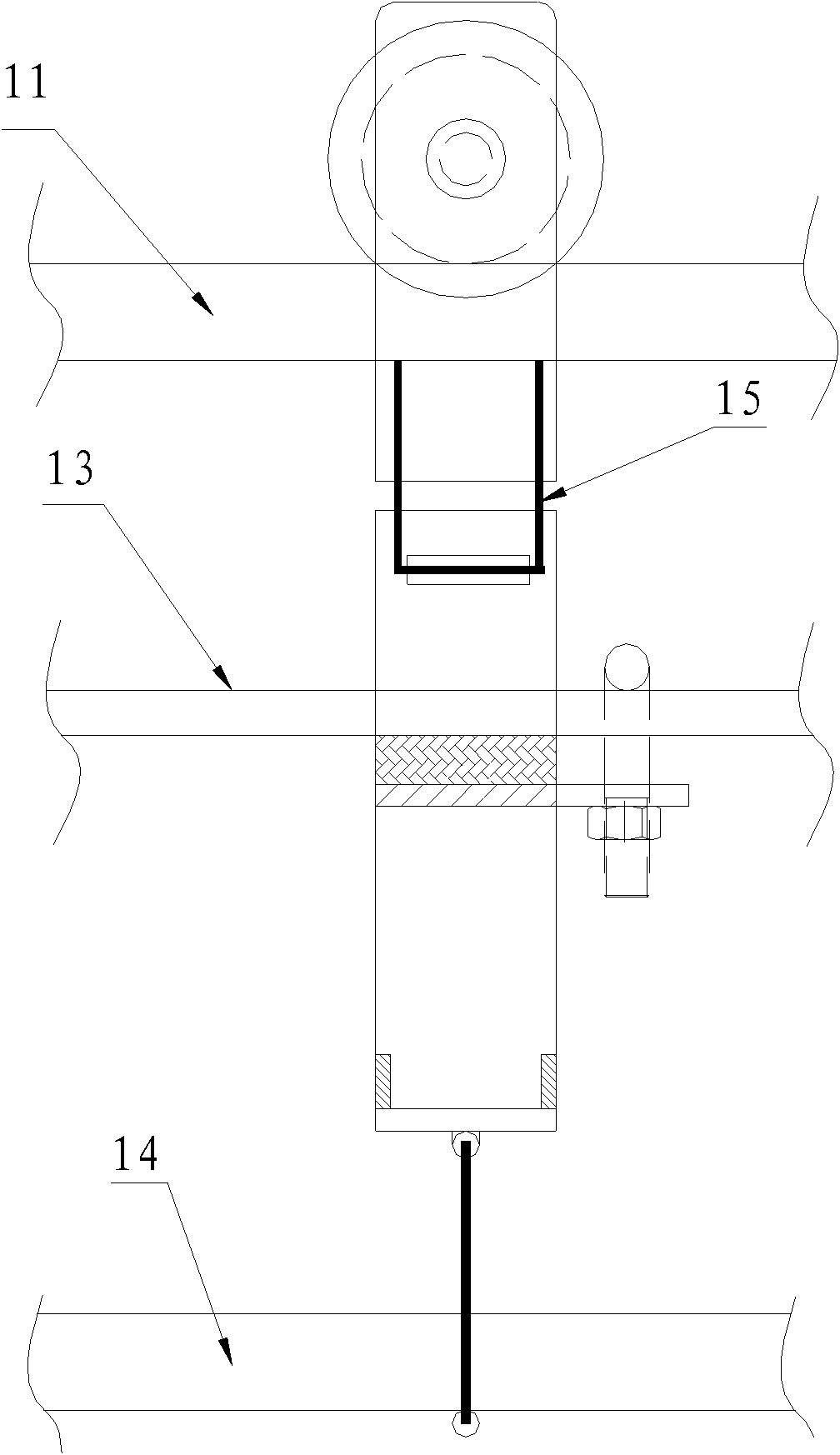

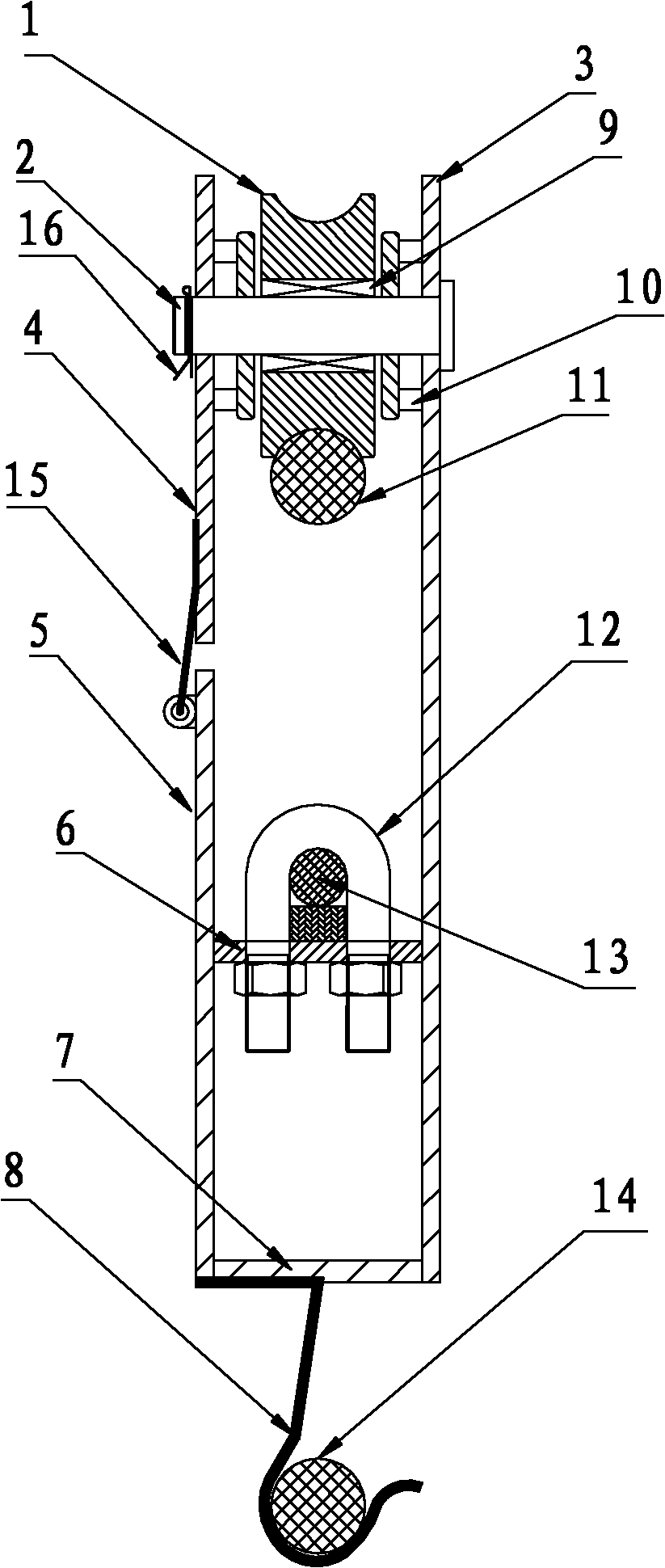

[0013] see figure 1 , 2 , the temporary support horse for cableway installation, including the traveling wheel 1, the bearing 9 embedded in it and the pin shaft 2, and also includes the main side plate 3, the upper side plate 4 and the lower side plate 5; the pin shaft 2 runs through the main side plate in turn 3. The bearing 9 and the upper side plate 4 are locked by the β pin 16; the upper side plate 4 is connected with the lower side plate 5 through the hinge 15; the lower side plate 5 is fixedly connected with the main side plate 3 through the bottom plate 7; the bottom plate 7 The lower end is welded with a bearing hook 8; a partition 6 is welded between the middle part of the lower side plate 5 and the main side plate 3; a connecting hole is provided on the partition 6, and a U-shaped snap ring 12 is set in it, and is fixed by bolts; the traveling wheel 1, a gasket 10 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com