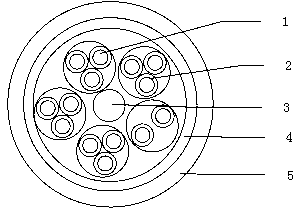

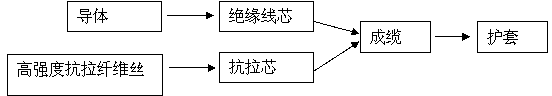

Towline cable and manufacturing process thereof

A towline cable and preparation process technology, used in cable/conductor manufacturing, insulated cables, bendable cables, etc., can solve the problem of no towline cable, etc., and achieve easy dragging, increased flexibility, excellent mechanical properties and electrical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] The sheath material adopts the extrusion process of low temperature resistant elastomer sheath material, extruded with 65 type extruder equipment, and adopts a double screw screw with a compression ratio of 25:1:

[0031] Process flow: preparation - mold matching - heating - adjusting mold - extrusion control - completion

[0032] 1) Preparation: equipment inspection, electrical inspection, turn on the power of the equipment, prepare production tools and product process cards;

[0033] 2) Die matching: the inner diameter of the core d = the outer diameter of the strand + (0.20~0.50) mm, the inner diameter of the mold sleeve = the nominal outer diameter of the finished product + (-0.1 ~ 0.1) mm; after the mold is determined, install the filter screen, Filter plate and die head, and feed after confirming that there is no debris in the hopper;

[0034] 3) Heating: After turning on the heating power, set the temperature of each section according to the extruded material: Z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com