Vertical disc twisting head of cable forming machine

A cable-forming machine and cable-forming technology, applied in the field of machinery, can solve problems such as difficulty in maintaining a uniform back-twisting shape, inconsistent twist of the cabled cables, and short cabled length at one time, achieving less power loss and large cabled length , low production and running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

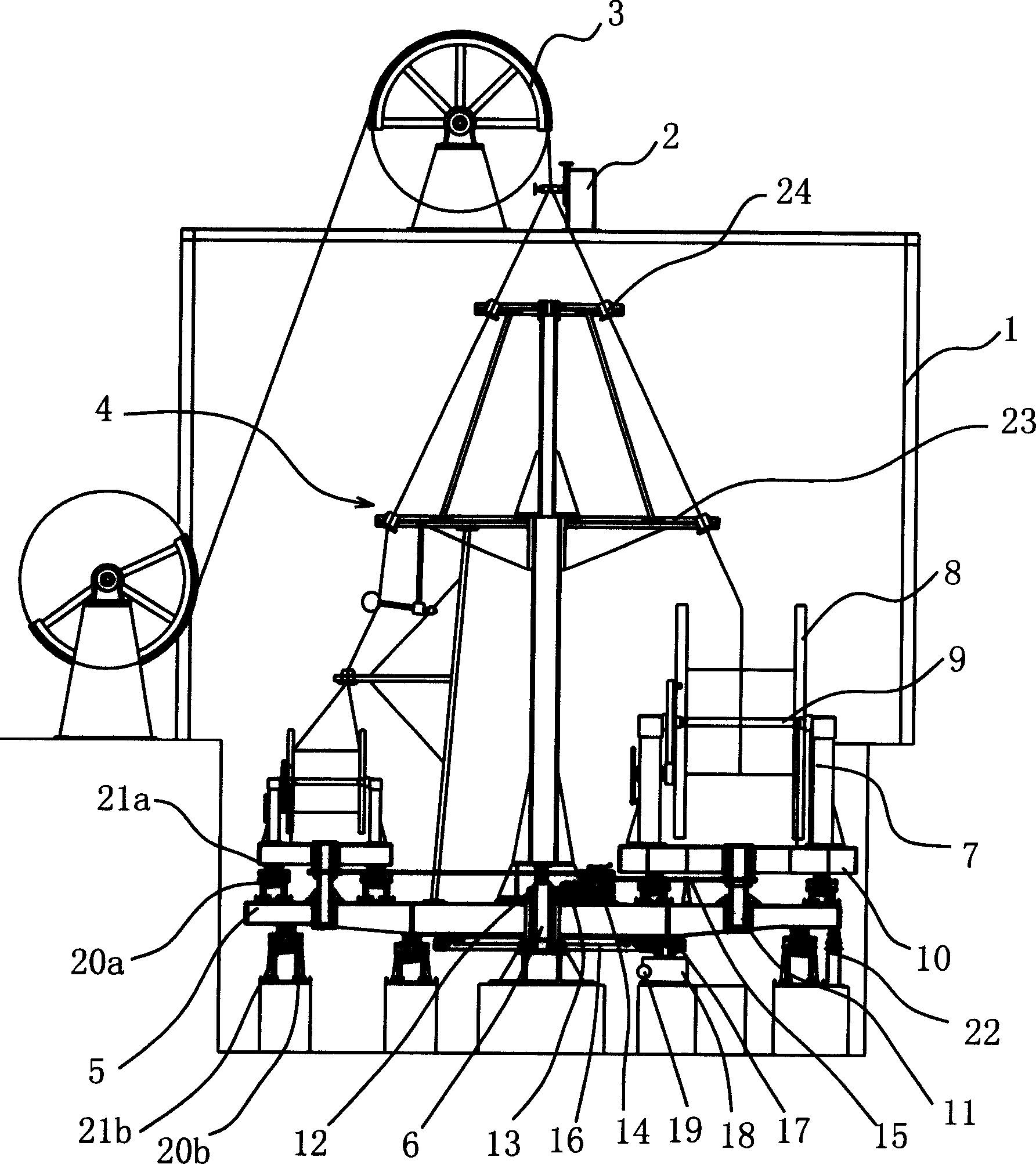

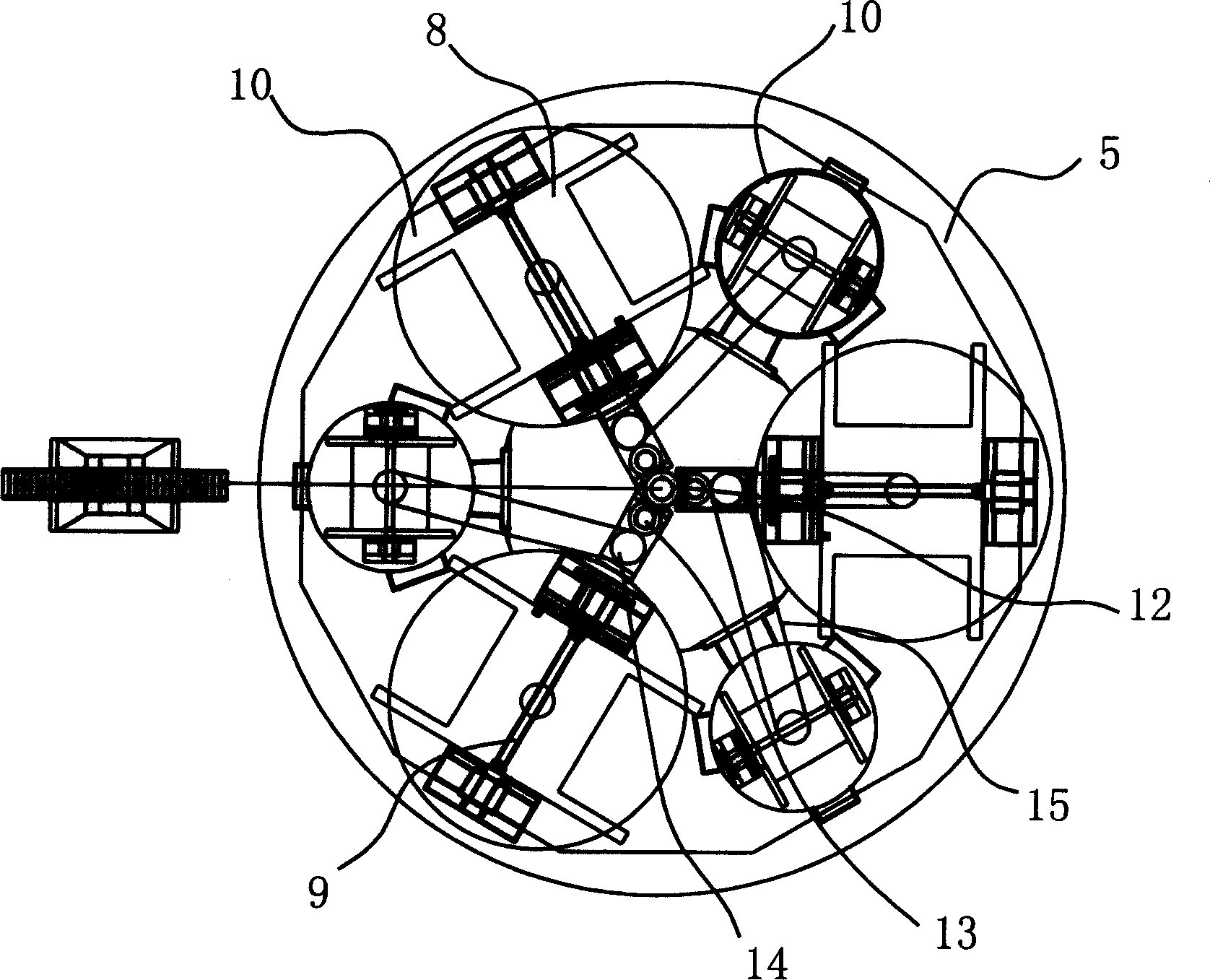

[0026] The vertical coil head of the cable forming machine, such as figure 1 , 2 As shown, it includes a cable-forming operation platform 1, a cable-doubling formwork frame 2 arranged on it, a steering wheel 3 is provided on one side of the cable-forming formwork frame 2, and a steering wheel 3 is provided under the cable-forming formwork frame 2. A support 4 is provided, and the support 4 is matched with the central axis 6 of the cabling turntable 5 . A plurality of crossbeams 23 are arranged on the support 4 , and a plurality of support wire bodies 24 are arranged on the crossbeams 23 . The central axis of the central shaft 6 is perpendicular to the horizontal plane, and several cable pay-off racks 7 are arranged on the cabling turntable 5. The axes are perpendicular to each other. Each cable pay-off rack 7 is respectively arranged on the back twisting disc 10, and the back twisting disc 10 is matched with the cabling turntable 5 through the rotating shaft 11. The centra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com