Cabling machine

A cable forming machine and cable technology, applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve problems such as troubles, loss of support for winding drums, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention provides a cable forming machine. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0028] In this paper, rear refers to the direction of cable movement, i.e. figure 1 The right side in the middle, the front and back are reversed.

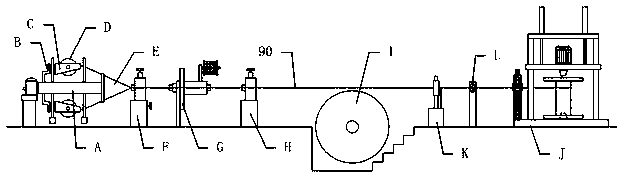

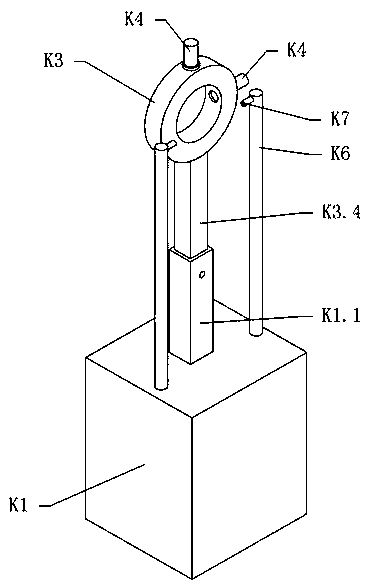

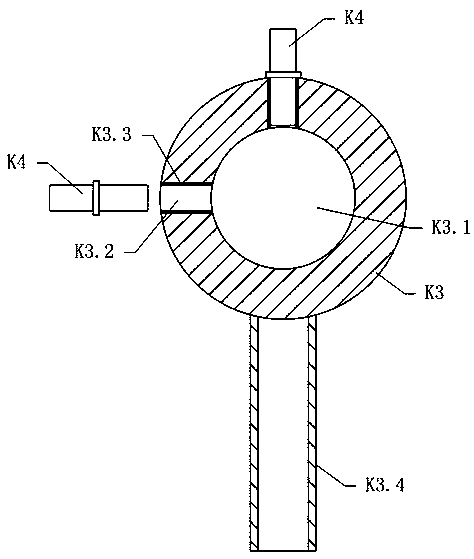

[0029] see Figure 1-9 , a cable forming machine provided by the present invention, comprising a hollow shaft A, an untwisting mechanism B, a hurdle C, a circular pay-off reel D, a splitter plate E, a main formwork frame F, a yarn wrapping head G, and a wrapping headform Frame H, traction wheel I, take-up device J, said take-up device J includes a base J1, a reel J2 vertically arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com