Harness cabling method

A realization method and a cable-forming technology, which are applied in the manufacture of wire harnesses, etc., can solve the problems of cable appearance damage, unstable cable tension, and low cable quality, so as to achieve improved cable quality, constant cable tension, and improved product quality. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

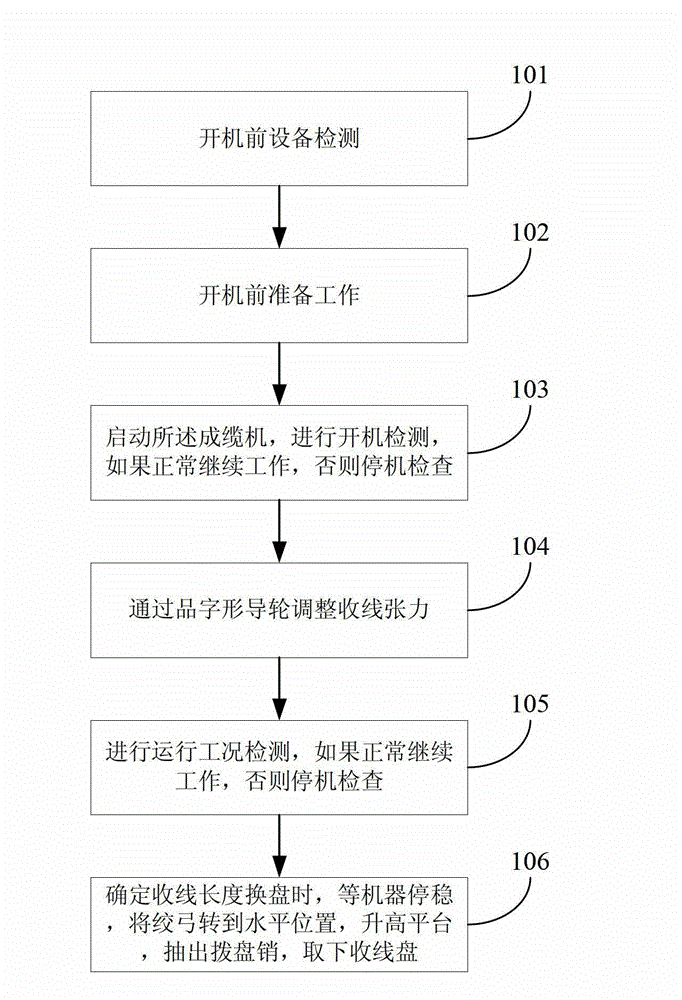

[0025] Embodiment 1 of the present invention provides a method for realizing cable forming of wire harnesses, which is applied to a cable forming machine including a pay-off frame, a wire passing wheel, a line distribution board, a cable forming mold, a wire arranging slider and a take-up reel. The method is as follows: figure 1 shown, including the following steps:

[0026] Step 101, device detection before booting. Specifically include: check whether the safety protection device is complete; check whether the pitch gear is loose; check whether the guide wheel can rotate flexibly; check whether the control handle of the take-up reel is loose and whether the safety pin slot is stuck in place; check the semi-finished pair twisted wire, including the color , Pitch confirmation; observe whether there is a fault display on the operation panel, preset various parameters, and check whether the display of each part is normal; and reset the meter counter to zero. Check the fixed nut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com