Automatic loading and unloading manipulator of drum type brake assembling line

A drum brake, automatic loading and unloading technology, which is applied in the direction of program-controlled manipulators, manipulators, automatic in/out workpieces, etc., can solve the problems of wasting manpower and material resources, low processing production efficiency, and high labor intensity, so as to reduce production and processing costs. , Improve the degree of automation and processing efficiency, reduce the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical solutions, technical features, objectives and automatic control effects realized by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

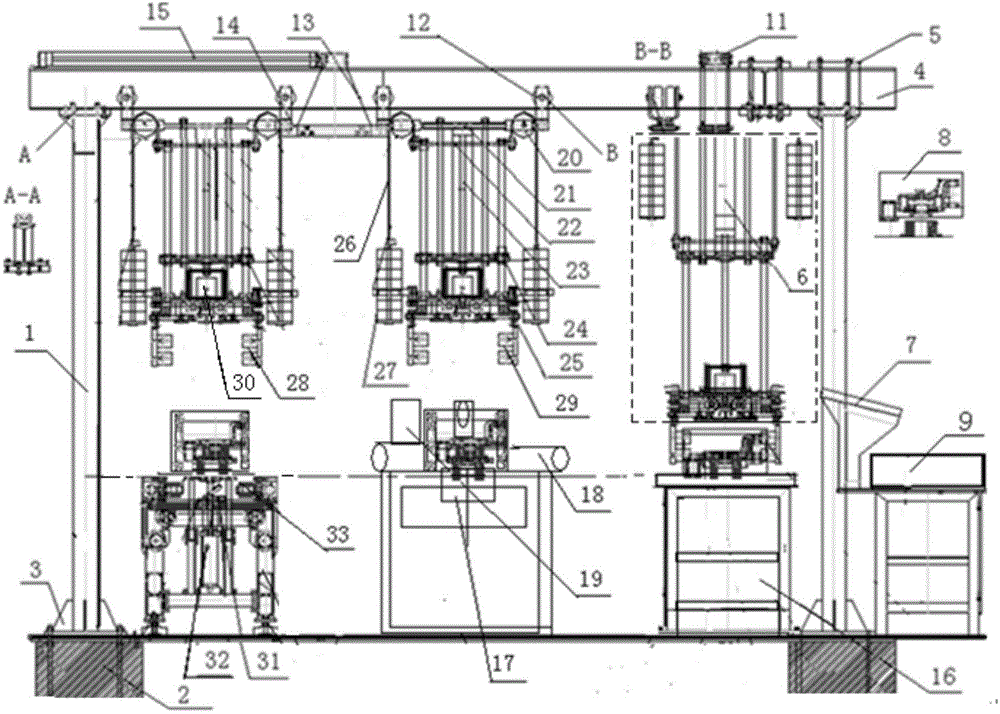

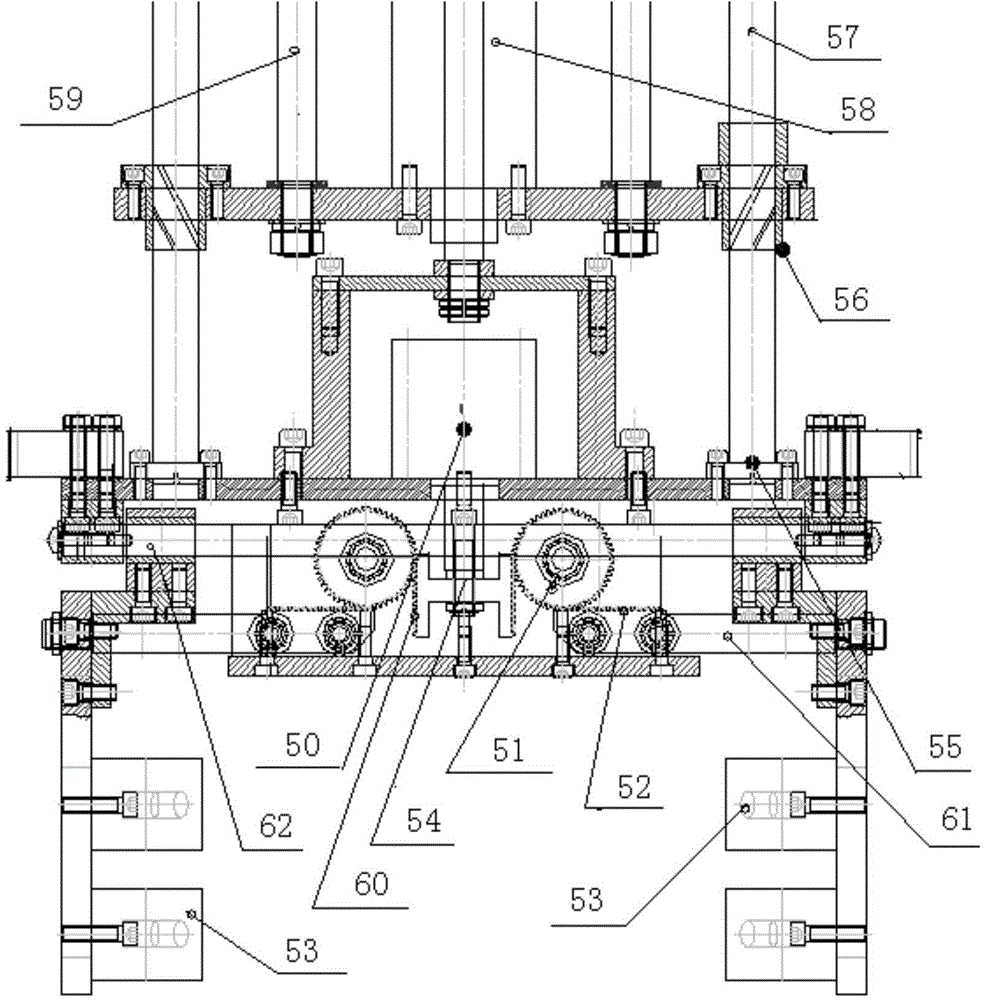

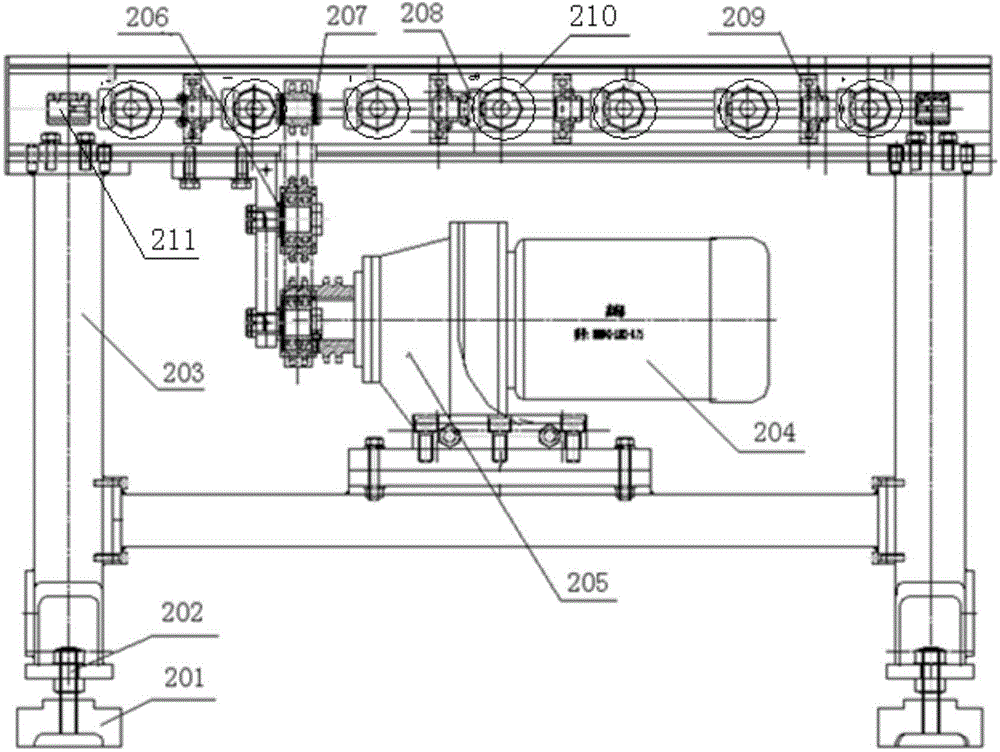

[0021] Such as figure 1 Shown: the automatic loading and unloading manipulator of the drum brake assembly line of the present invention, comprising: the gantry column frame 1 base 3 is integrally fixed on the ground foundation 2, above the gantry is an I-shaped upper beam 4 with a beam connecting plate 5 and 4 and stud bolts are fixed, and two conjoined spearhead hanging rollers 12 are hung on the upper beam 4 of the gantry. The spearhead hanging roller 12 is fixedly connected with the manipulator fixed plate 21, and the two ends of the fixed plate are provided with a sprocket wheel and a balance counterweight 27; It is fixed as a whole with it, and is fixedly connected with the translation cylinder support 13 on the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com