Double-metal hot jacket integrated automobile brake drum and machining method thereof

A processing method and bimetal technology, applied in the field of brake drums, can solve the problems of increased processing and assembly difficulty, poor safety, loose liners, etc., and achieve the effect of light weight, compact material and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

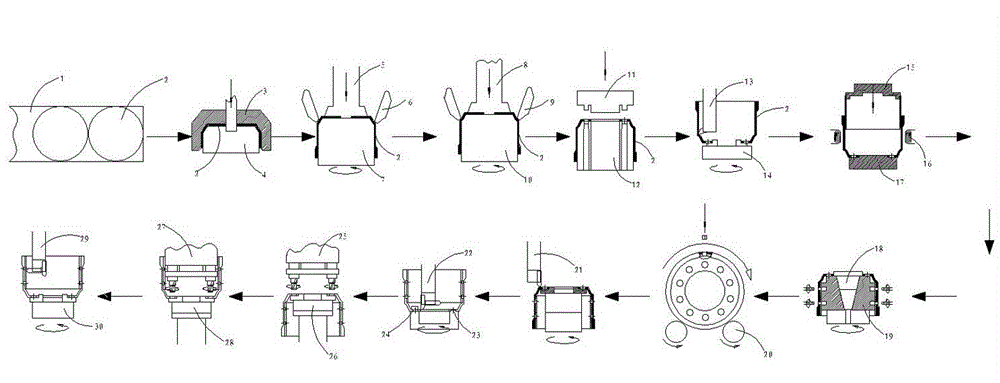

[0029] Such as figure 1 Shown, a kind of processing method of bimetallic heat sleeve integrated automobile brake drum, its processing steps are:

[0030] In the first step, the steel plate 1 is selected, and the laser cutting machine cuts the circular blank 2 first.

[0031] The second step is to use the frame hydraulic press to preform and punch the positioning hole. a. The circular blank 2 workpiece is placed on the lower mold 4. b. After the center of the outer circle is roughly positioned, the upper mold 3 goes down. c. Preform the workpiece and punch the center positioning hole.

[0032] The third step is "coarse spinning" of spinning. The workpiece is placed on the mandrel 7. After the center is roughly centered, the upper press seat 5 moves down to position and compress the workpiece. The spindle drives the workpiece to rotate, and the rotary wheel 6 of the spinning machine moves Spinning.

[0033] The fourth step is "fine spinning" of spinning. The workpiece is plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com