Carbon composite materials comprising particles of metal carbides dispersed therein and method for producing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

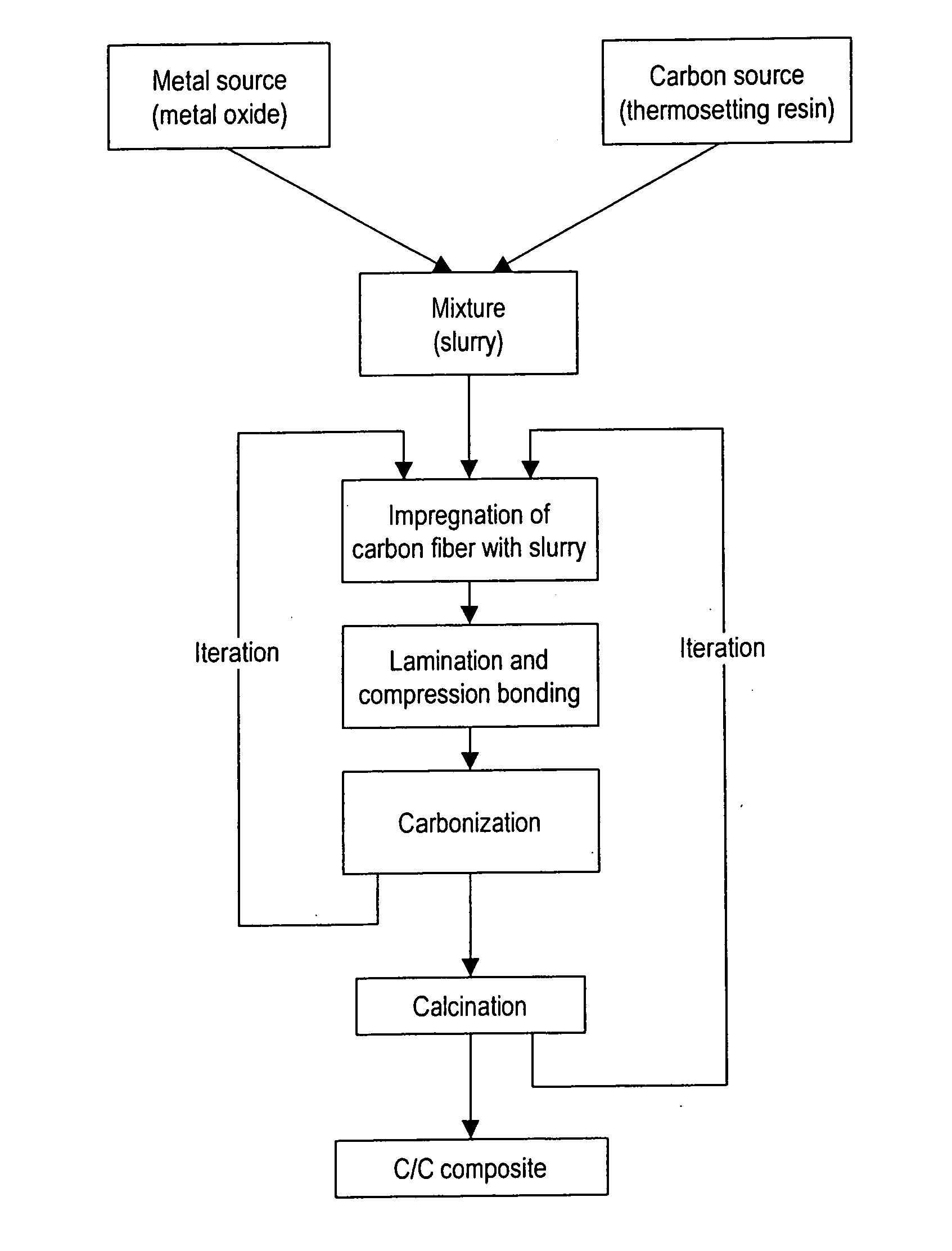

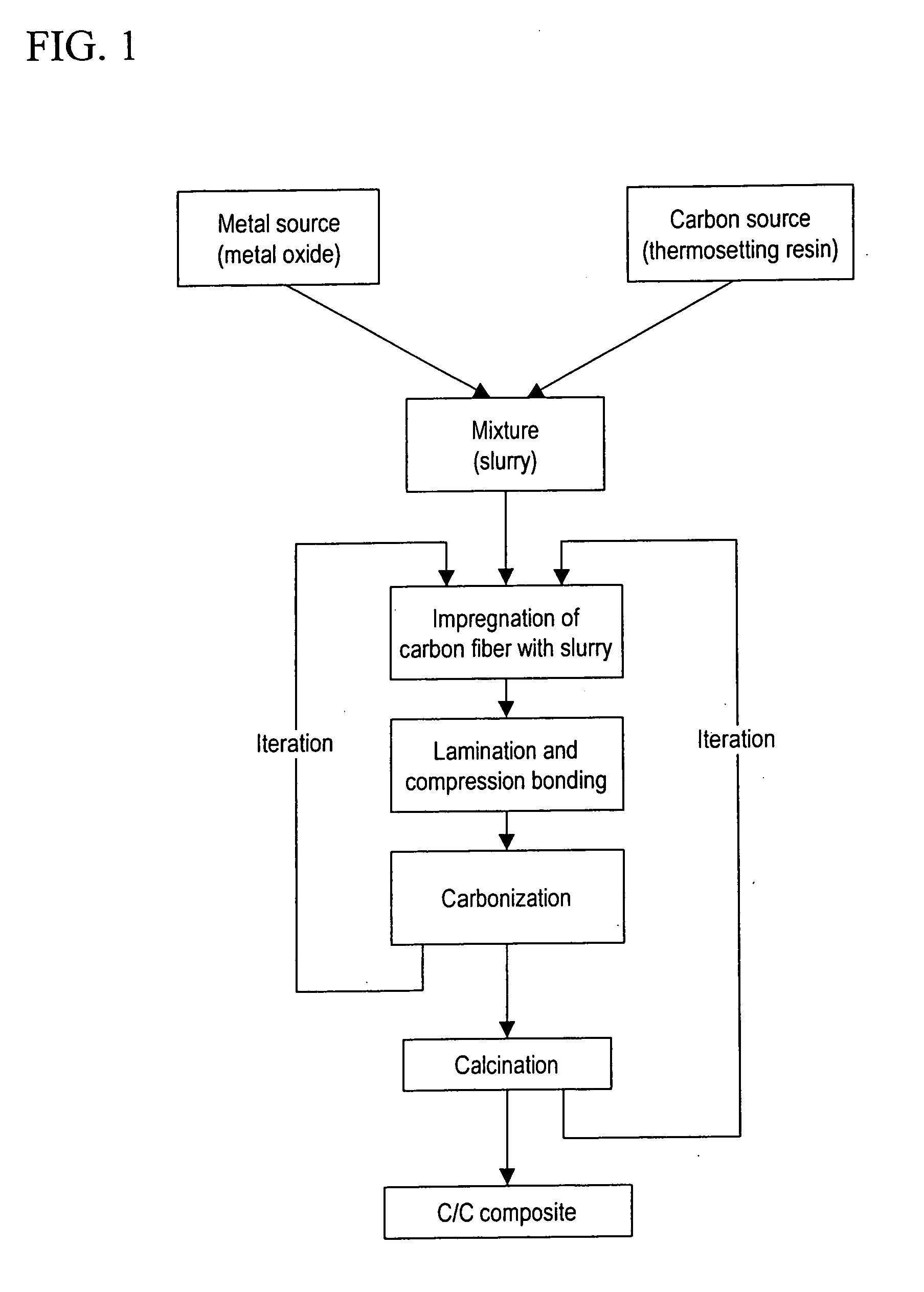

Method used

Image

Examples

examples

[0058] Starting materials of 1) silica particles with an average particle diameter of 3 μm and 2) liquid phenol resin were used. Silica particles were introduced into liquid phenol resin with a dispersant to adjust their concentrations to a C:Si ratio of at least 3:1, in terms of molar ratio. In this example, silica particles were mixed at a ratio of C:Si of 9:1, in terms of molar ratio.

[0059] A carbon sheet was impregnated with the aforementioned slurry, followed by molding via heating. After molding, the dispersion state of silica particles was observed under an electron microscope, and the photograph shown in FIG. 2 was obtained.

[0060] The molding product was subjected to carbonization in an inert gas atmosphere at 1000° C.

[0061] The carbon sheet was reimpregnated with phenol resin in a vacuum container, followed by recarbonization. Thereafter, the molding product was subjected to calcination in an inert gas atmosphere at 1650° C. The resulting test piece was observed under an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com