Method and device for monitoring brake lining wear and air clearance of an operating brake in motor vehicles

A technology of service brakes and brake linings, applied in the direction of brake type, axial brake, brake safety system, etc., can solve the problem of unrecognizable brake unintentional feeding, incompatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

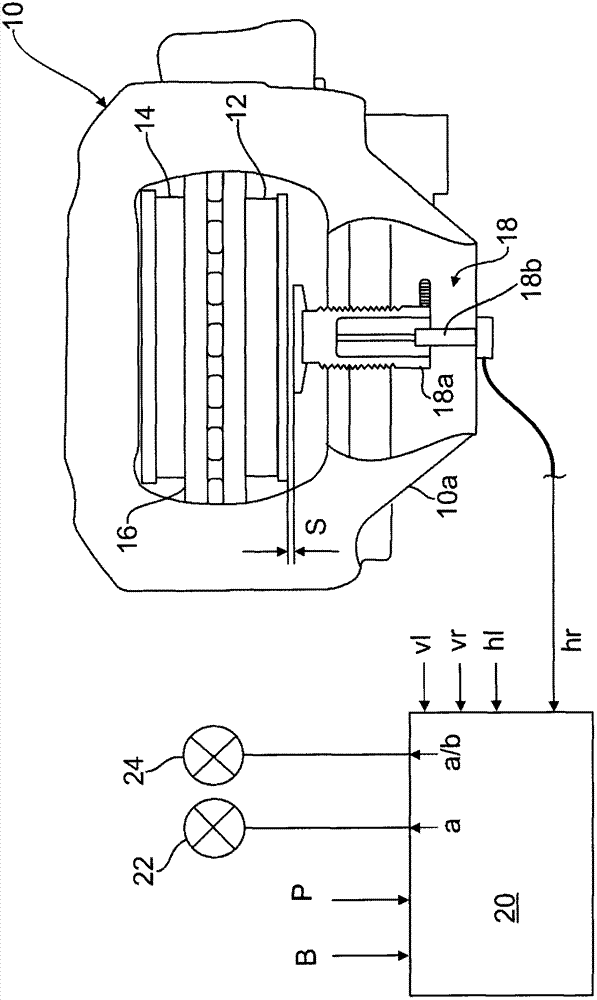

[0013] 10 in the drawing indicates a brake caliper, which forms part of a disc brake of a wheel of a motor vehicle and whose brake linings 12 , 14 with the lining carrier pass through the not shown of the service brake of the motor vehicle. The feed unit can be pressed against a brake disc 16 (only partly shown). The brake caliper 10 may be of a known construction type and is shown and described only as necessary for the understanding of the invention.

[0014] A linear displacement sensor 18 is integrated into the brake caliper 10 , which is functionally connected with its housing 18 a on the one hand to the feed device or hydraulic piston (not visible) and on the other hand with its measuring probe 18 b to the brake caliper. At the housing 10a of the movable caliper 10 and with an actuated service brake, it detects the changed position of the feed device relative to the housing 10a of the brake caliper 10 as signal value a.

[0015] In the case of an unactuated service brak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com