Braking equipment for motor vehicles

A technology of braking equipment and motor vehicles, applied in the direction of brakes, vehicle components, brake transmissions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

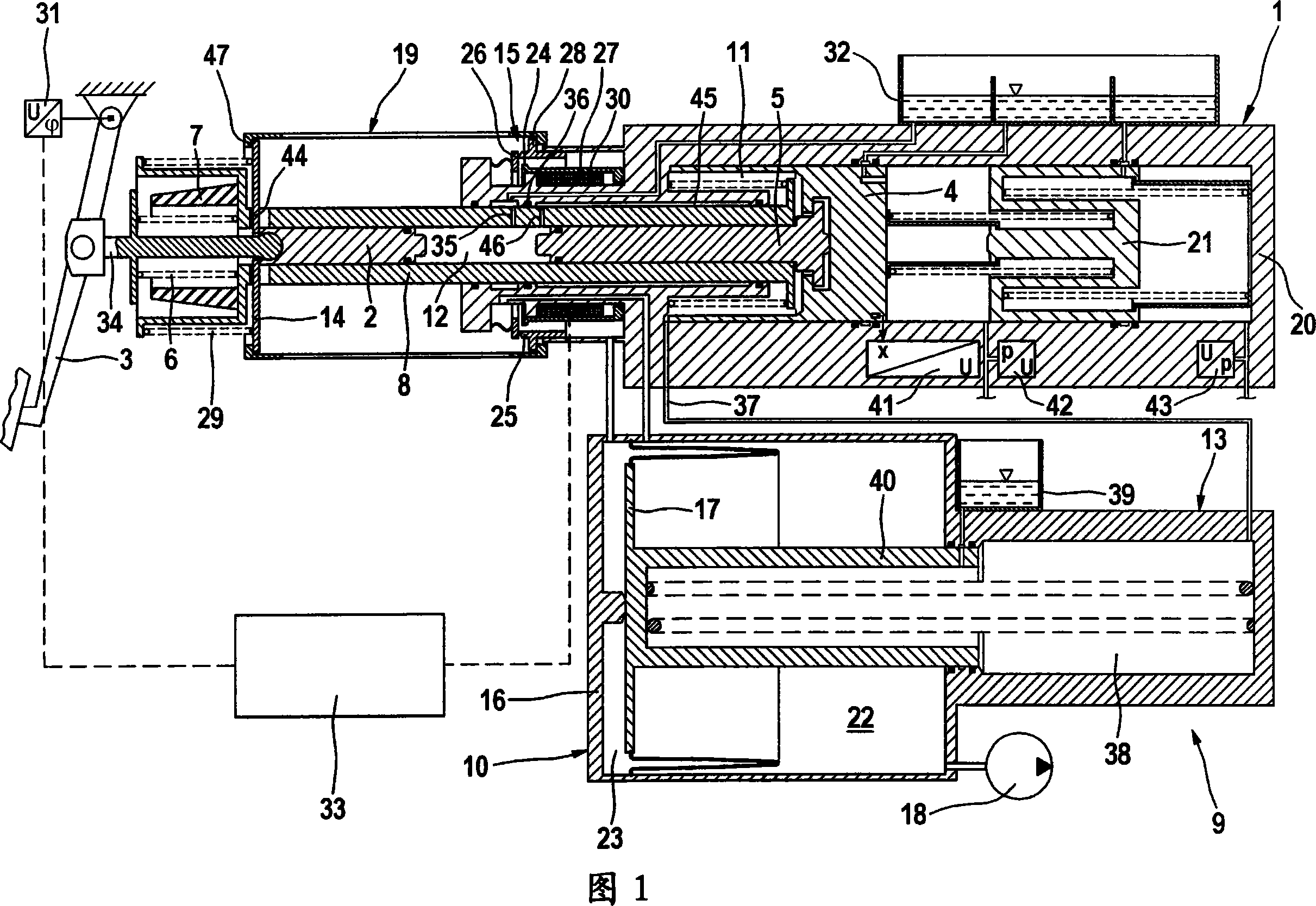

[0035] The brake system according to the invention shown in the figures has a brake pedal 3 which is operatively connected to the first piston 2 via an operating rod 34 . The brake pedal stroke can be detected by a rotational angle sensor 31 . Furthermore, a second piston 4 is provided, which is the actuating piston of master brake cylinder 1 . In the example shown, the master actuating cylinder 1 is designed as a tandem master cylinder, in whose master cylinder housing 20 a further piston 21 is connected to the second piston 4 . The wheel brakes of the vehicle can be connected to master brake cylinder 1 via a controllable wheel brake pressure modulation module, not shown, wherein an electronic control unit and regulating unit, also not shown, is assigned to the wheel brakes. Pressure modulation module. As an alternative or in addition to the angle of rotation sensor shown, a travel sensor can be provided which detects the actuation travel of the push rod 34 or of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com