System with valve device for a pneumatically operated brake system, valve device, brake actuation device, trailer control valve device, and device for controlling for the system, brake system, vehicle, use of a component, and method for retrofitting

A technology of brake equipment and brake control, which is applied in the system field of valve devices, and can solve the problems of initial equipment and modification costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

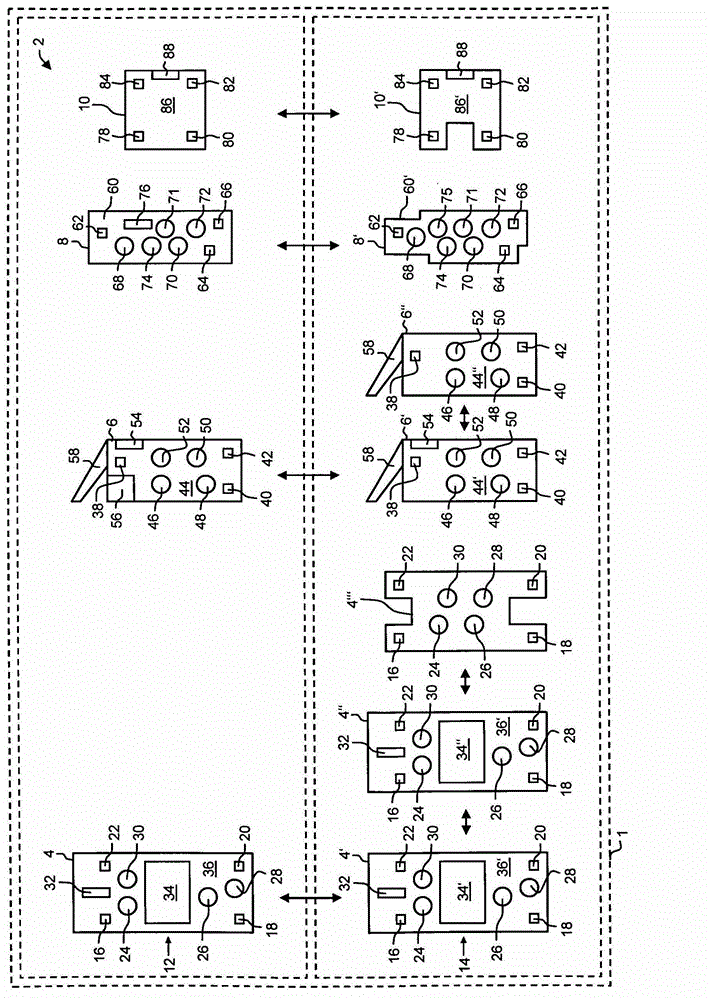

[0056] figure 1 A system 1 for a pneumatic braking device is shown. The system 1 is designed modularly, in particular as a modular system, and has a plurality of replacement components 2 . The replacement component 2 is a valve device 4 , a brake actuating device 6 , a trailer control valve device 8 and a device 10 for control. From these replacement components 2 , the system each has at least one first variant 12 and at least one second variant 14 . The first and second variants 12 and 14 of each replacement component 2 can each alternatively be installed or installed in the brake system.

[0057] For example, the brake system can initially have all replacement components 2 in the form of the first variant 12 . All or individual replacement components 2 can, for example, be replaced by a respective second variant 14 of the respective replacement component 2 for a changeover of the brake system. The replacement of identically or identically configured variants 12 or 14 wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com